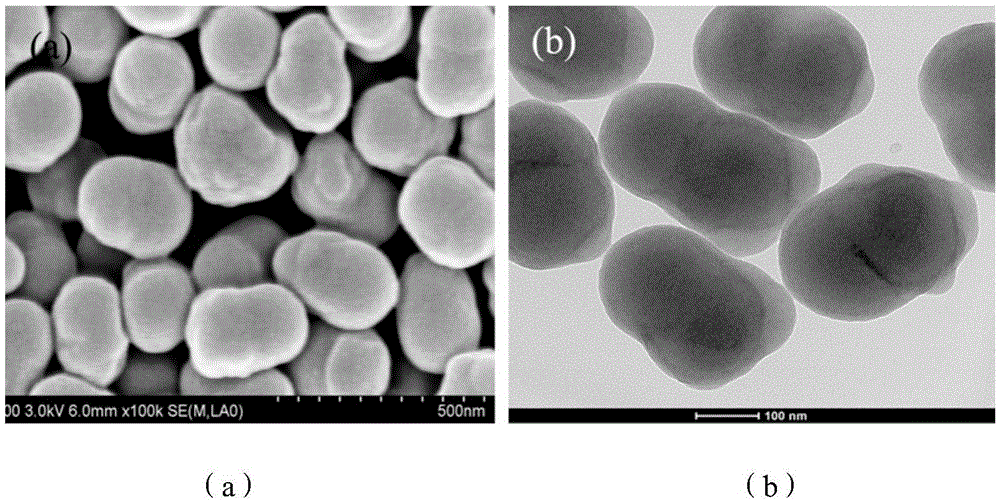

Preparation method of dumbbell-shaped janus colloidal particles

A colloidal particle and dumbbell-shaped technology, which is applied in the field of colloidal particle preparation, can solve the problems of wide particle size distribution, large Janus particle size, and restrictions on the preparation and application of Janus particles, and achieve the effect of simple operation and easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Disperse 0.08g sodium dodecylbenzenesulfonate in 95mL deionized water, stir and disperse for 0.5h in a 250mL four-neck flask equipped with a stirrer, reflux condenser, nitrogen protection device and water bath heating, and the stirring speed is 350rpm; Under the protection of nitrogen, add 4.5g of vinyltriethoxysilane and 5.5g of styrene monomer mixture that has been ultrasonically treated (power 200W; frequency 40KHz) for 10 minutes into a four-necked flask, continue to stir for 30 minutes, and heat up to 75°C. Add 5 mL of ammonium persulfate (concentration: 0.018 g / mL) aqueous solution dropwise, and continue to react at the reaction temperature for 8 hours, then stop stirring, cool to room temperature, and obtain a stable white emulsion, which is centrifuged and washed to obtain dumbbell-shaped Janus colloidal particles .

Embodiment 2

[0019] Disperse 0.05g sodium dodecylsulfonate in 95mL deionized water, stir and disperse for 0.5h in a 250mL four-neck flask equipped with a stirrer, reflux condenser, nitrogen protection device and water bath heating, stirring speed 350rpm; Under protection, add 4g of vinyltrimethoxysilane and 5g of styrene monomer mixture that has been ultrasonically treated (power 200W; frequency 40KHz) for 10 minutes into a four-necked flask, continue stirring for 30 minutes, raise the temperature to 75°C, and drop 5mL of Ammonium persulfate (concentration: 0.018g / mL) aqueous solution, and continue to react at the reaction temperature for 8h, then stop stirring and cool to room temperature to obtain a stable white emulsion, which is centrifuged and washed to obtain dumbbell-shaped Janus colloidal particles.

Embodiment 3

[0021] Disperse 0.064g sodium dodecylsulfonate in 95mL deionized water, stir and disperse for 0.5h in a 250mL four-necked flask equipped with a stirrer, reflux condenser, nitrogen protection device and water bath heating, stirring speed 350rpm; Under protection, add 3g of methylvinyldiethoxysilane and 6g of styrene monomer mixture that has been ultrasonically treated (power 200W; frequency 40KHz) for 10min into a four-necked flask, continue stirring for 30min, raise the temperature to 75°C, and pour into the system Add 5mL of 2,2'-azobisisobutylamidine dihydrochloride (concentration: 0.018g / mL) aqueous solution dropwise, and continue to react at the reaction temperature for 10h, then stop stirring and cool to room temperature to obtain a stable white The emulsion was centrifuged and washed to obtain dumbbell-shaped Janus colloidal particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com