Isotropic high-strength polypropylene composite material and preparation method thereof

An isotropic, composite material technology, applied in the field of high-strength polypropylene composite materials and their preparation, can solve the problem that the isotropy of whiskers is not fully exerted, the effect interval is not at the same level, and the four-needle whiskers are very different. Large and other problems, to achieve fine distribution, ensure processing performance, and improve the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

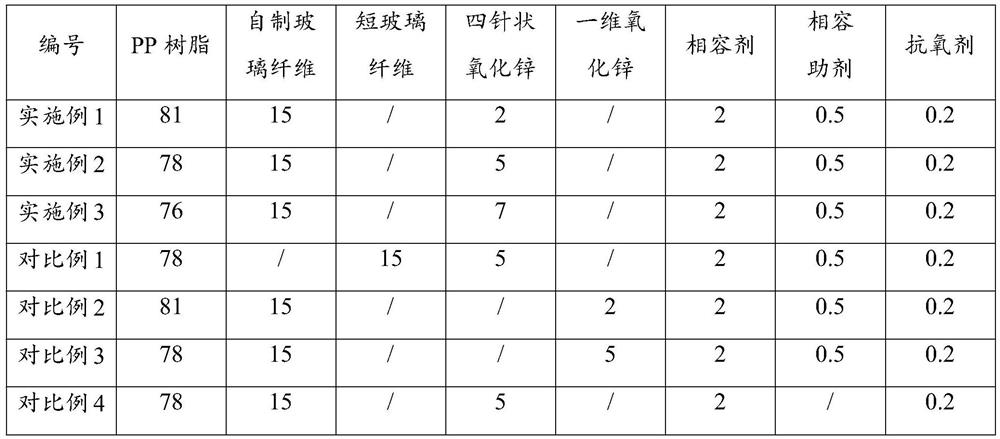

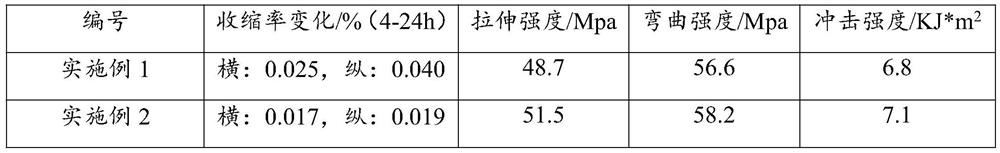

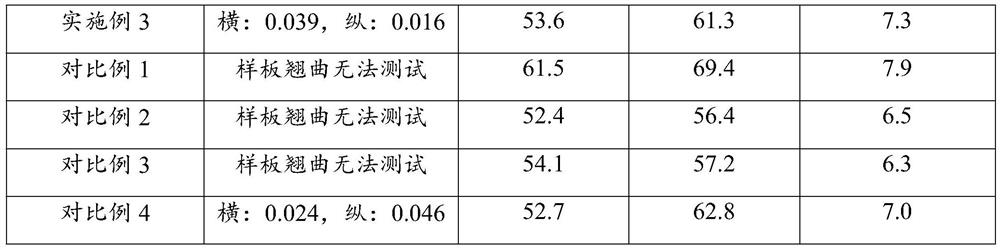

Examples

preparation example Construction

[0047] The preparation method of described self-made glass fiber comprises the steps:

[0048] S1. Material selection

[0049] The raw materials are weighed according to the proportion, wherein the mass proportion of each component is: alkali-free glass fiber 1-40, acrylic resin 55-94 and compatibilizer 5;

[0050] S2, mixing

[0051] Slowly mix the above raw materials in the air, and control the mixing speed to 80-100r / min;

[0052] S3, feed extrusion

[0053] Add the mixed material from the main feeding port of the twin-screw extruder, control the speed of the main machine to 300-400r / min, and control the extrusion temperature to 190-210°C;

[0054] S4, preprocessing

[0055] The extruded strips are water-cooled, air-dried and fully homogenized;

[0056] S5. Calcination

[0057] Put the pretreated strip into a muffle furnace for calcination to remove excess matrix, and control the calcination temperature at 650-750°C. The residue obtained after calcination is the finis...

Embodiment 1

[0067] An isotropic high-strength polypropylene composite material includes the following components, and the mass ratio of each component is: PP resin 81, self-made glass fiber 15, tetrapod zinc oxide whisker 2, compatibilizer 2, Compatibility additive 0.5, antioxidant 0.2.

[0068] The production raw materials of the self-made glass fiber include the following components, and the mass ratio of each component is: alkali-free glass fiber 1, acrylic resin 55 and compatibilizer 5.

[0069] The preparation method of described self-made glass fiber comprises the steps:

[0070] S1. Material selection

[0071] Weigh the raw materials according to the ratio;

[0072] S2, mixing

[0073] Slowly mix the above raw materials in the air, and control the mixing speed to 80r / min;

[0074] S3, feed extrusion

[0075] Add the mixed material from the main feed port of the twin-screw extruder, control the speed of the main machine to 300r / min, and control the extrusion temperature to 190°...

Embodiment 2

[0088] An isotropic high-strength polypropylene composite material includes the following components, and the mass ratio of each component is: PP resin 78, self-made glass fiber 15, tetrapod zinc oxide whisker 5, compatibilizer 2, Compatibility additive 0.5, antioxidant 0.2.

[0089] The production raw materials of the self-made glass fiber include the following components, and the mass ratio of each component is: 40 alkali-free glass fibers, 94 acrylic resins and 5 compatibilizers.

[0090] The preparation method of described self-made glass fiber comprises the steps:

[0091] S1. Material selection

[0092] Weigh the raw materials according to the ratio;

[0093] S2, mixing

[0094] Slowly mix the above raw materials in the air, and control the mixing speed to 100r / min;

[0095] S3, feed extrusion

[0096] Add the mixed material from the main feeding port of the twin-screw extruder, control the speed of the main machine to 400r / min, and control the extrusion temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com