Carbon fiber composite aircraft window frame and manufacturing method thereof

A manufacturing method and carbon fiber technology are applied in the field of carbon fiber composite aircraft window frames and their manufacturing, and can solve problems such as the inability of metal materials to meet requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

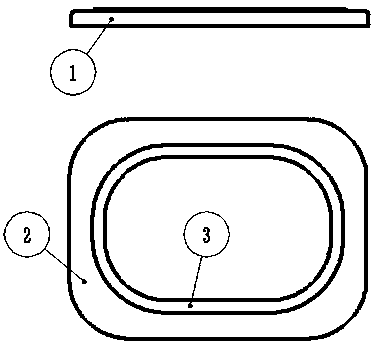

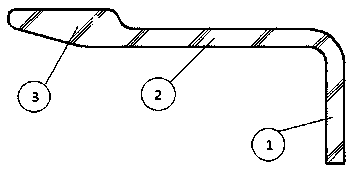

[0019] like figure 1 As shown, a carbon fiber seamed aircraft window frame includes a flange 1, a web 2 and a lip 3, and the web 2 is connected to the fuselage skin by fasteners. The window frame is a laminated structure, adopts an integrated design, and is formed as a whole. After laying the sub-prefabricated body, it is RTM formed, and the transparent part is clamped in the variable thickness area.

[0020] The manufacturing method of the carbon fiber jointed aircraft window frame specifically comprises the following steps:

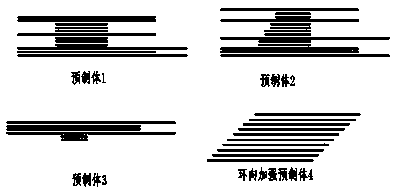

[0021] Step 1: Through the joint laying process, four sub-prefabricated bodies are manufactured; as image 3 shown.

[0022] Step 2: Lay the four sub-prefabricated bodies in a certain order into the inner cavity of the mold, and then put them into the oven to prepare the prefabricated body of the entire aircraft window frame....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com