Spindle blade of textile machine spindle

A spindle and spindle rod technology, which is applied in the direction of textiles and papermaking, can solve the problems that affect the twist of the yarn and cannot be matched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

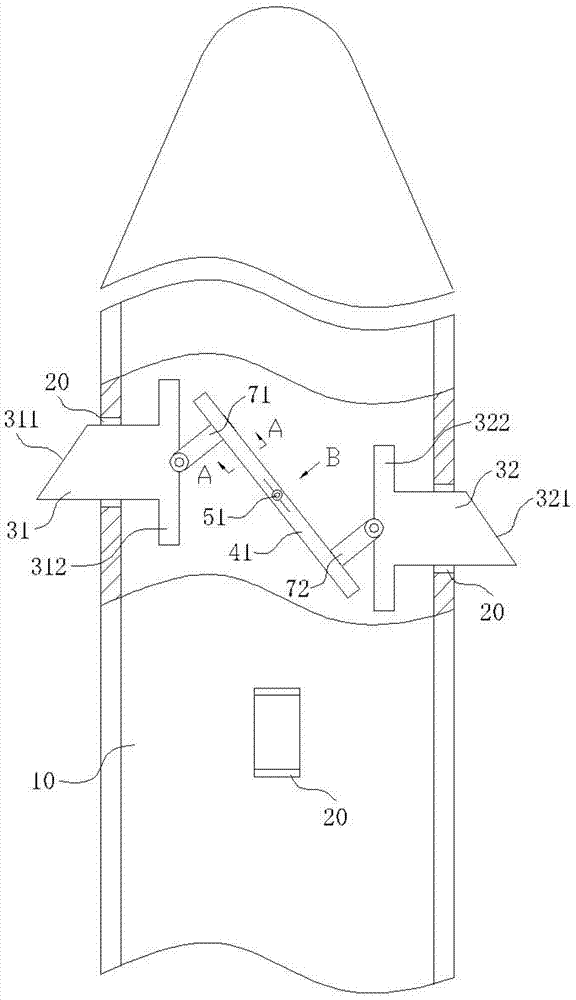

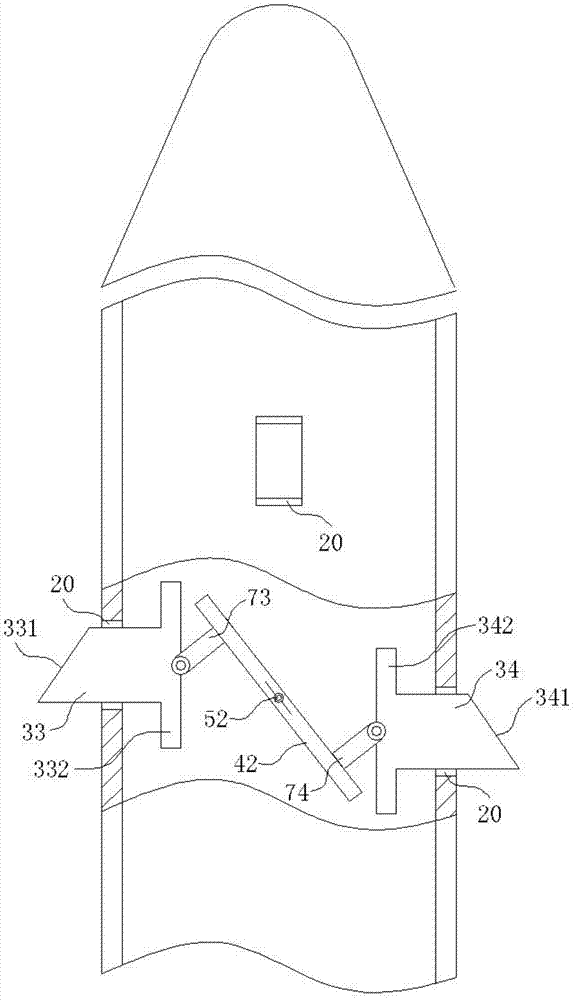

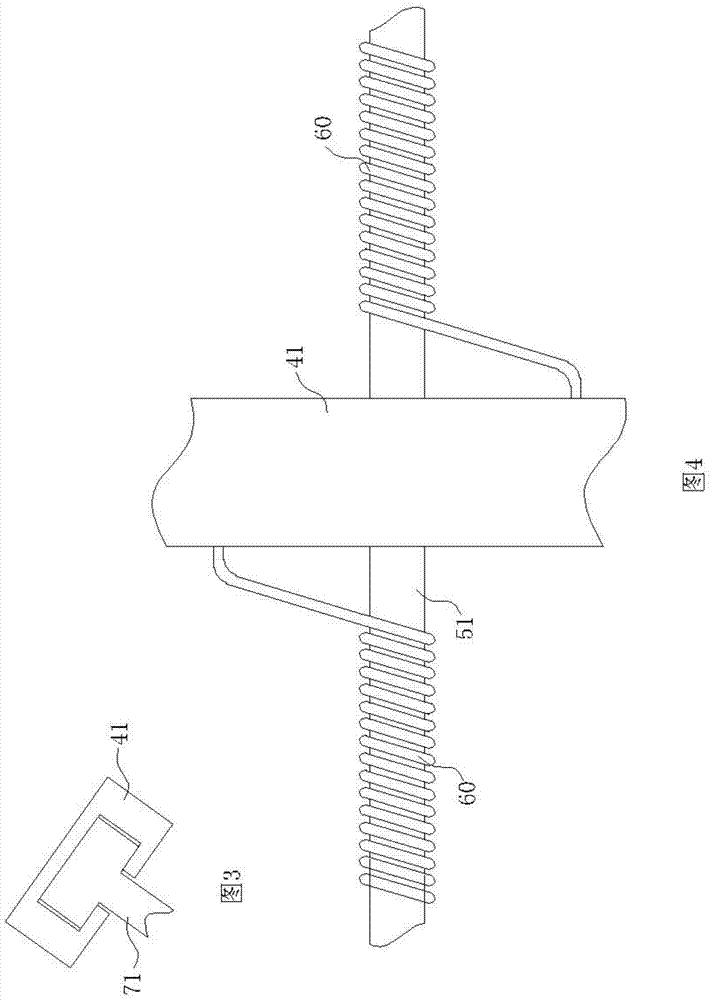

[0024] like Figure 1~4 As shown, a spindle rod of a spinning machine spindle includes a hollow rod body 10, four openings 20 provided on the rod body 10, a telescopic block 31, a telescopic block 32, a telescopic block 33, and a telescopic block that can expand and contract in the opening 20. Block 34, the four openings 20 are evenly distributed along the circumference of the rod body 10, the telescopic block 31, the telescopic block 32, the telescopic block 33, and the telescopic block 34 are located on the outer part of the rod body and are provided with inclined surfaces 311, 321, and 331. The slope 341, the telescopic block 31, the telescopic block 32, the telescopic block 33, and the telescopic block 34 are located inside the rod body 10 and are provided with a protruding part 312, a protruding part 322, a protruding part 332 and a protruding part 342. It also includes a lever 41 and a lever 42. The telescopic block 31 and the telescopic block 32 are movably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com