Low-pressure EGR control during compressor bypass valve operation

一种压缩机、旁通阀的技术,应用在发动机操作、发动机控制、电气控制等方向,能够解决发动机性能衰退、不能实现进气空气稀释等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

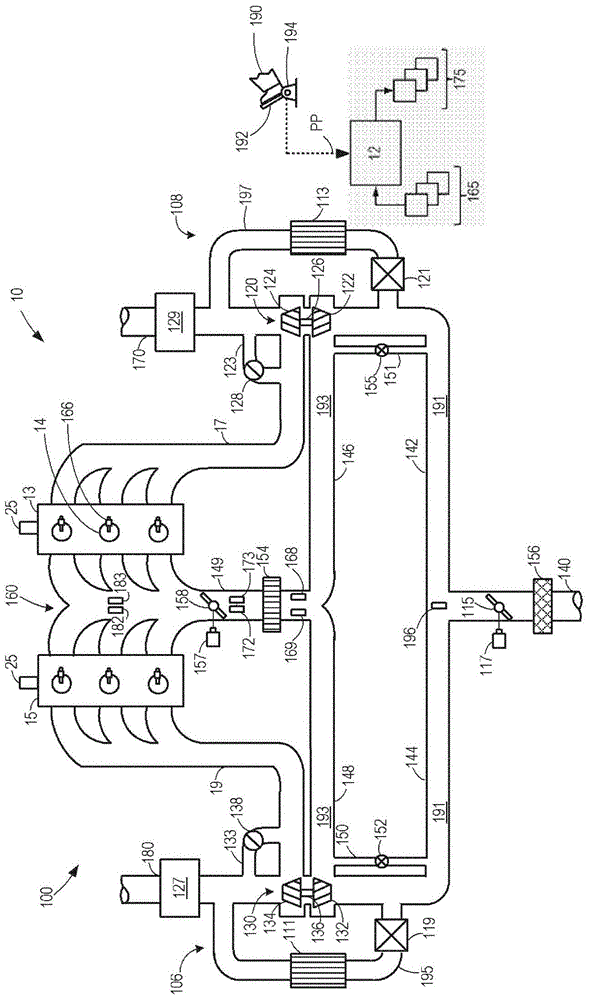

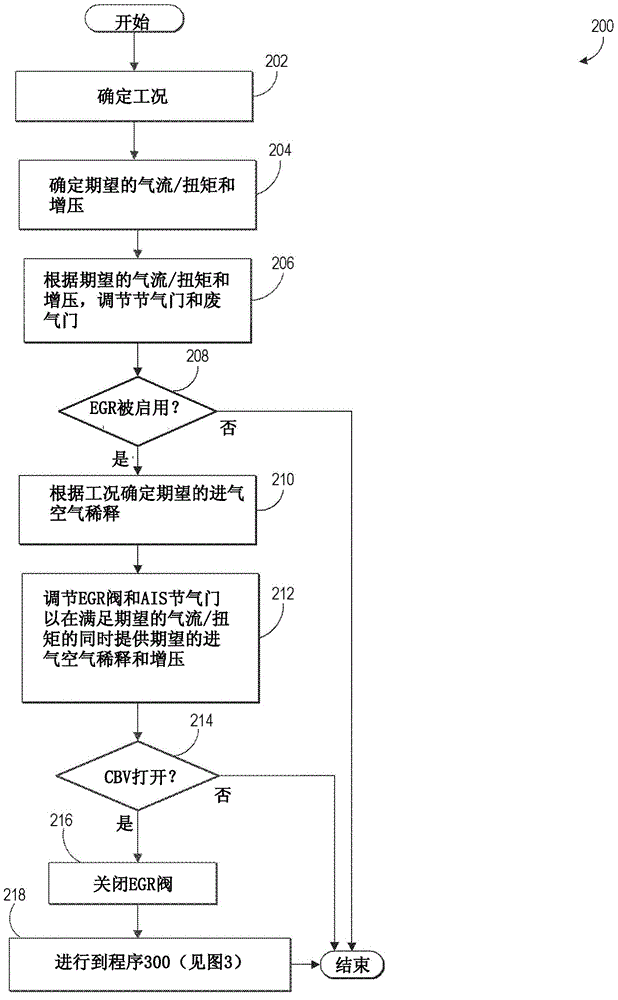

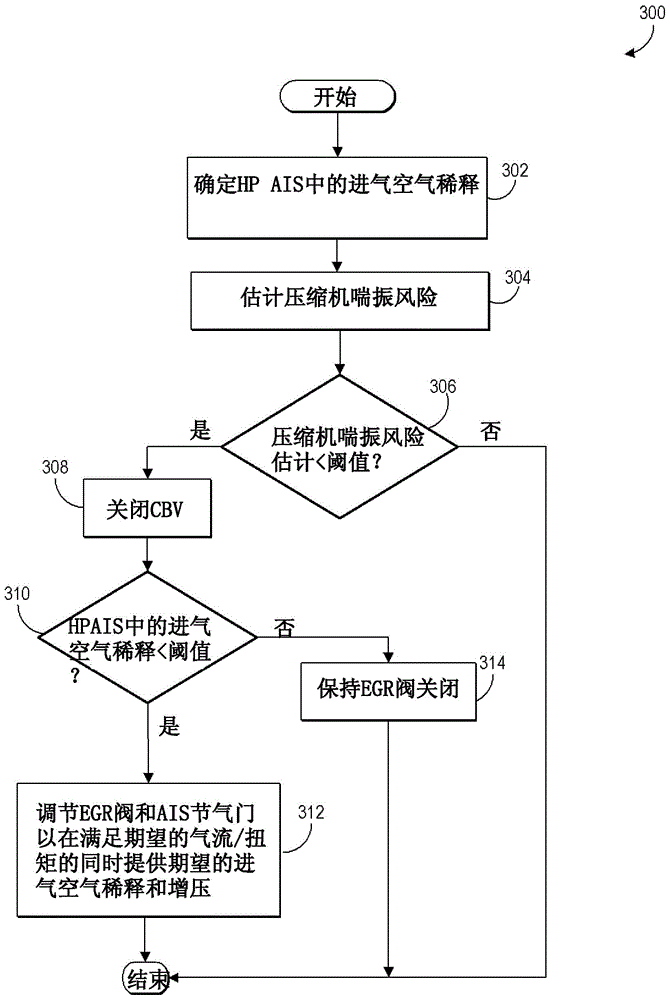

[0010] The following description relates to controlling LP EGR during CBV operation in an internal combustion engine. Such as figure 1 As shown in the exemplary embodiment of , an engine system may include two branches, each branch having a turbocharger and an EGR system. An intake oxygen sensor placed downstream of the compressor can measure the dilution of the intake air, which can be used as a basis for adjusting CBV and EGR, as described in the figure 2 and 3 The procedure is described in detail. For example, if figure 2 and 3 As shown, when the CBV is open, the EGR valve may be closed to avoid excessive dilution of the intake charge. Such as Figure 4 As shown in the timing diagram of , once the CBV closes (for example, due to compressor surge risk estimates falling below a threshold), and once the measured intake air dilution reflects that the intake system contains little or no EGR, then EGR may be increased as needed to achieve the desired dilution of intake a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com