Method for designing non-circular gear planetary system through Fourier function segment transmission ratios

A segmented transmission ratio, non-circular gear technology, applied in planting methods, transmissions, gear transmissions, etc., can solve the problem that it is difficult to find non-circular gear pitch curve function expressions, designers have high experience requirements, and it is difficult to Find the needle trajectory of the planting mechanism and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the present invention more comprehensible, it will be described in detail as follows in conjunction with the embodiments and accompanying drawings.

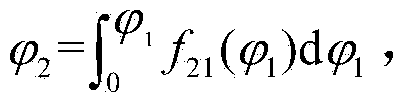

[0039] The rotary splitting mechanism of the high-speed rice transplanter is mainly composed of a sun gear 1, a first middle wheel 2, a second middle wheel 4, a first planetary wheel 3, a second planetary wheel 5, a first needle 6, and a second needle 8 and a gear box 7; the gear box 7 is a planet carrier H, and the rotation axes of the sun gear 1, the first intermediate gear 2, the second intermediate gear 4, the first planetary gear 3, and the second planetary gear 5 are located on the same straight line , the sun gear 1 is fixedly connected to the frame, its rotation axis coincides with the rotation center of the planet carrier H, and the rotation center D of the first intermediate gear 2 is in the middle of the rotation center O of the sun gear 1 and the rotation center A of the first planetary gear 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com