Method for detecting backlash

A backlash and measurement error technology, applied in the field of gap crossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

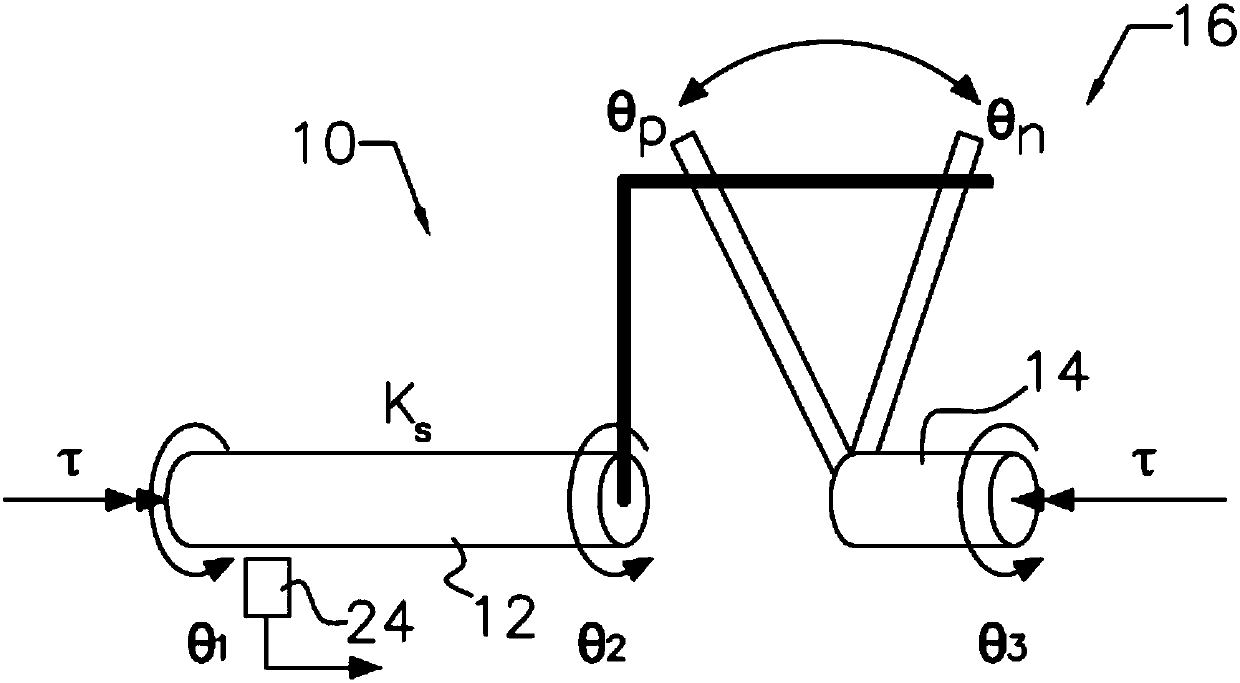

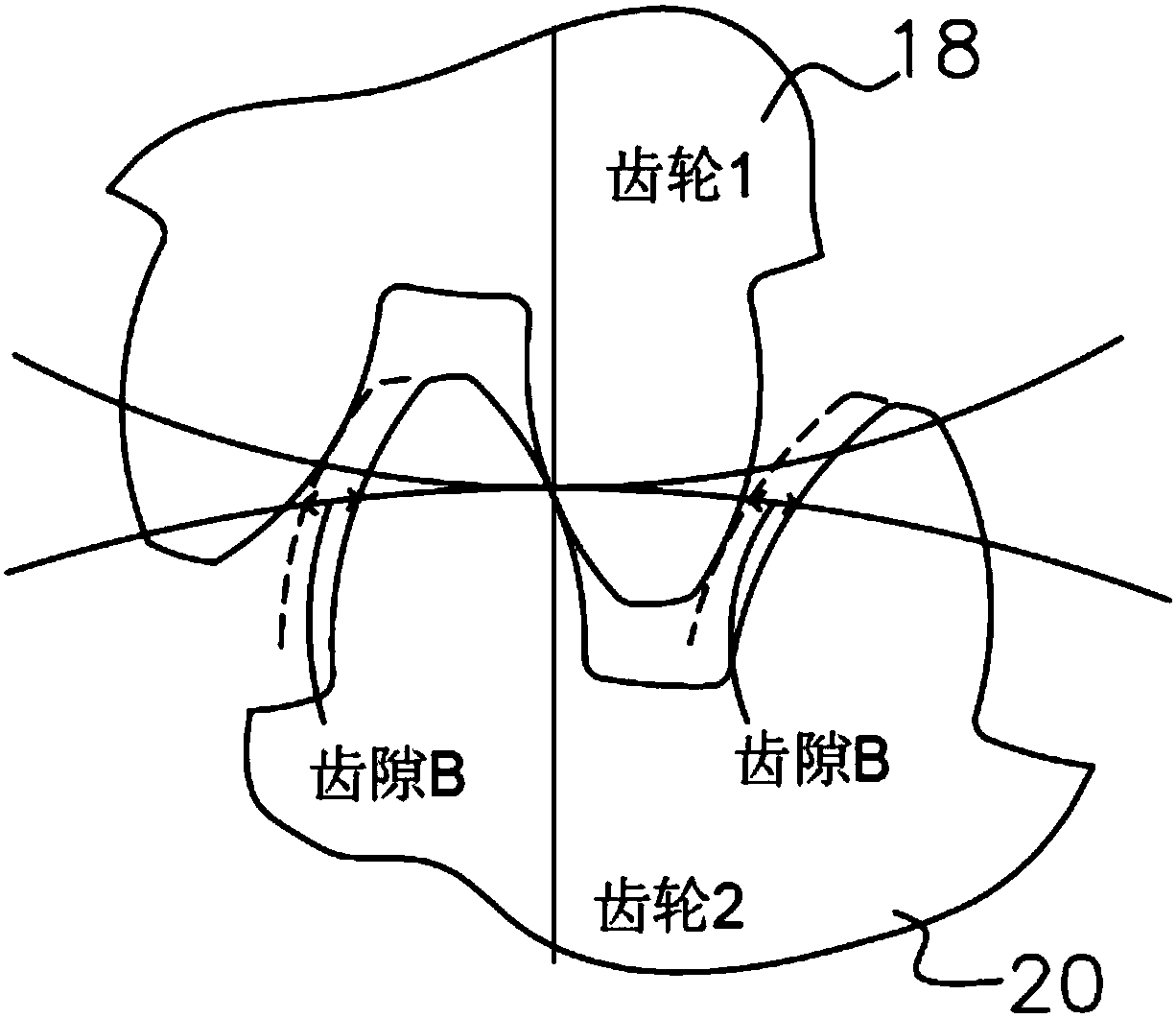

[0017] figure 1 A drive train 10 is shown having two shafts 12 , 14 connected by a torsional discontinuity 16 in which backlash may occur. pass figure 2 The discontinuity 16 is represented by meshing gears 18 , 20 , each fixed to one of the shafts 12 , 14 . The magnetoelastic shaft torque sensor 24 suitable for mass production and capable of directly measuring the torque at the transmission input shaft or output shaft realizes many functions in vehicle control. The dynamic response of axle torque sensor 24 is within a fraction of a millisecond, which far exceeds any currently available on-board torque estimate. Therefore, this torque measurement enables robust backlash detection and useful feedback for motor vehicle drivability control.

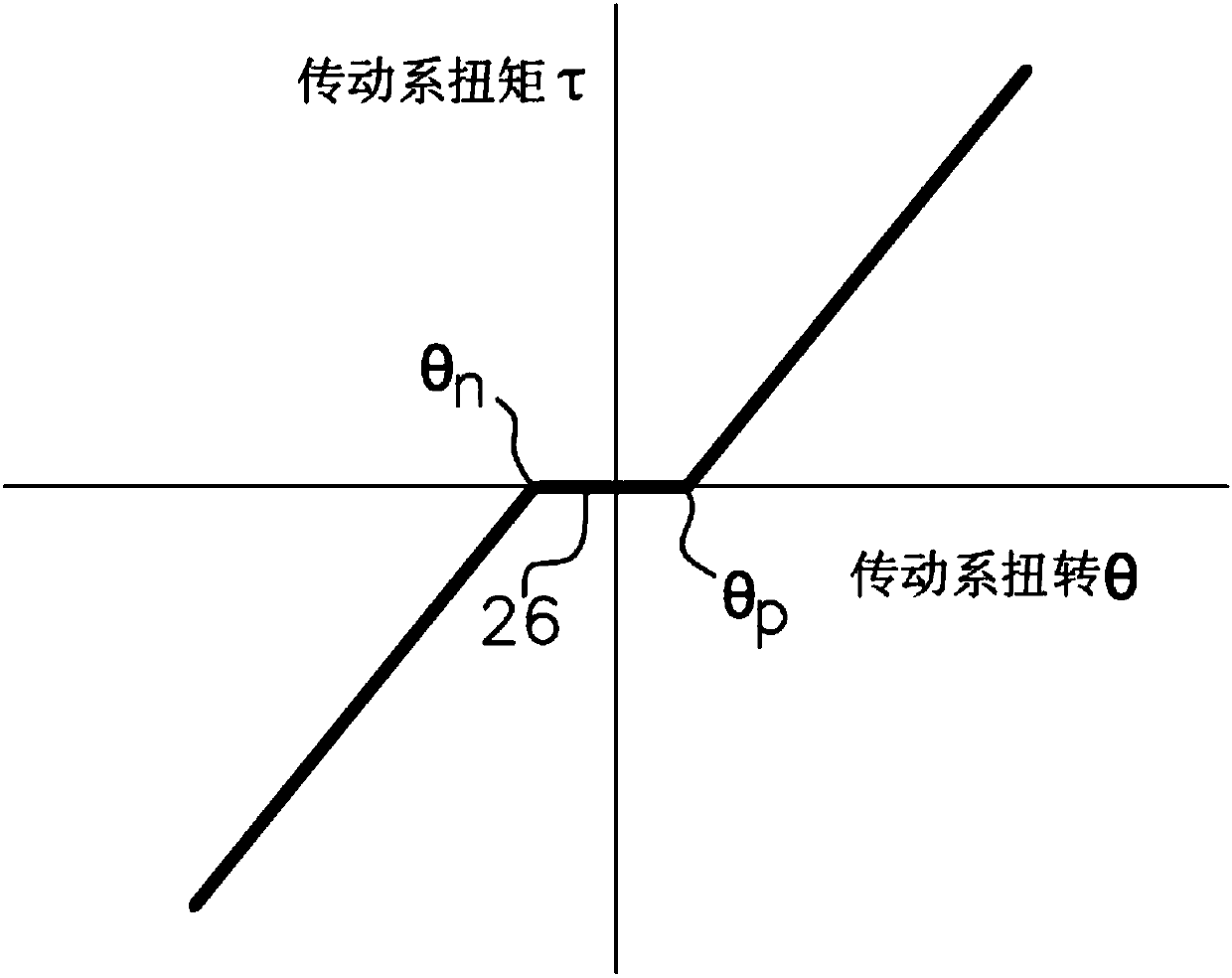

[0018] image 3 is a graph showing the change in driveline torque τ and twist θ from negative torsion angles to positive torque angles (including discontinuities θn, θp entering or leaving lash region 26 (ie, gap crossing).

[0019] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com