Gas chromatograph for analysing total-hydrocarbon constituents of gasoline and diesel catalytic cracking products

A gas chromatograph and catalytic cracking technology, which is applied in the field of instruments for analyzing catalytic cracking products, can solve the problems of large space occupation, high development cost, complex system, etc., and achieve the effect of convenient operation, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

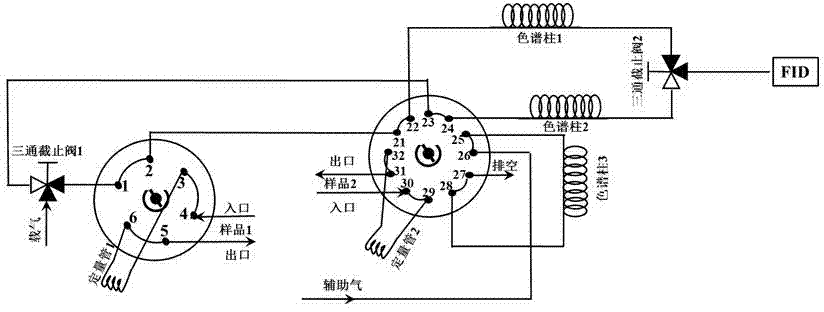

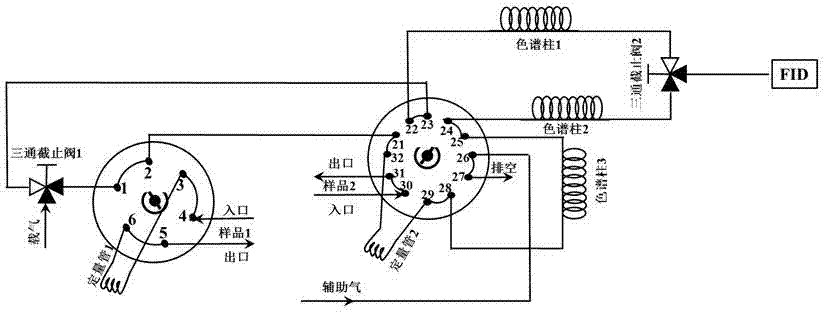

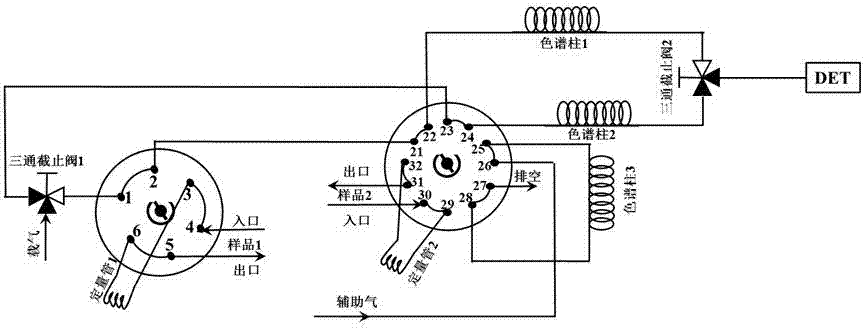

[0026] refer to figure 1 , the instrument is in standby backflush state, carrier gas N 2 The circuit is: carrier gas inlet → three-way stop valve 1 middle path → three-way stop valve 1 right path → six-way valve channel 1 → six-way valve channel 2 → twelve-way valve channel 21 → twelve-way valve channel 22 → chromatographic column 1→Three-way stop valve 2 left path→Three-way stop valve 2 middle path→FID detector; sample 1 circuit is: six-way valve channel 4→six-way valve channel 3→quantitative tube 1→six-way valve channel 6→six-way Valve channel 5; sample 2 circuit is: 12-way valve channel 30→12-way valve channel 29→quantitative tube 2→12-way valve channel 32→12-way valve channel 31; backflush circuit is: auxiliary gas→10 Two-way valve channel 26→twelve-way valve channel 25→chromatographic column 3→twelve-way valve channel 28→twelve-way valve channel 27; in column selection, from three-way stop valve 1 to chromatographic column 2 to three-way stop The detailed route of valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com