Rotary rapid eyeglass leg replacement structure

A mirror foot and mirror frame technology, which is applied in the field of rotating and quick-changing mirror foot structures, can solve problems such as inconvenient operation, achieve the effects of easy disassembly and carrying, satisfying mirror foot matching, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

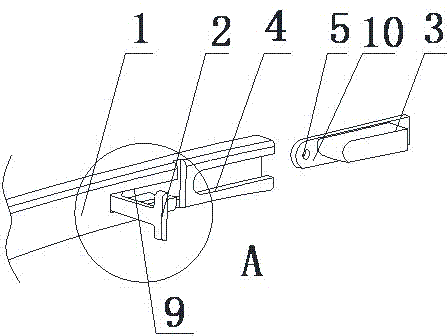

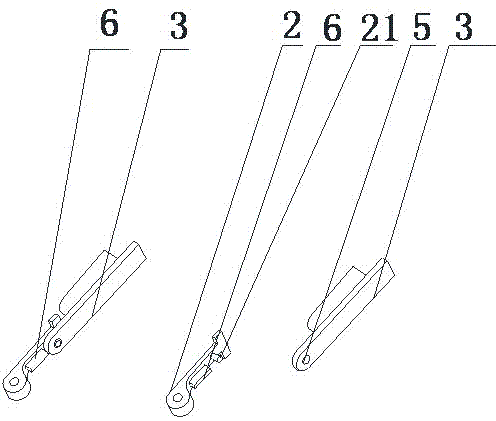

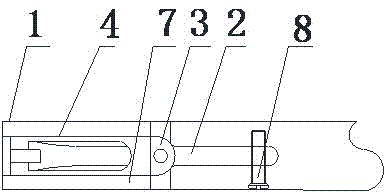

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a mirror frame with a frame foot connection 3 and a mirror foot 1 matched with the frame foot connection 3, a "T" shaped pressure block 2 is arranged on the mirror foot 1, and a A groove 9 is provided to cooperate with the "T"-shaped pressure block, and the groove 9 is provided with a sliding groove 4 near the connection of the frame foot connection 3, and the frame foot connection 3 is arranged in the sliding groove 4, the "T"-shaped pressing block 2 is provided with a positioning post 21, and the frame foot connection 3 is provided with a positioning connection hole 5 that cooperates with the positioning post 21.

[0019] Such as figure 1 As shown, the "T"-shaped pressing block 2 is provided with a positioning protrusion 6, and the groove 9 is provided with a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com