Optimization method for aging temperature and time of automotive electronic components

A technology of electronic components and aging temperature, applied in the direction of unstructured text data retrieval, etc., can solve the problems of reducing aging efficiency, too long time, affecting aging effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is applicable to the optimization method of aging temperature and time of automobile electronic components and comprises the following steps:

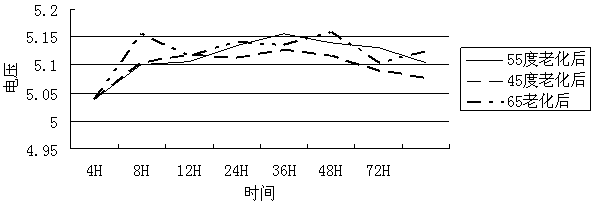

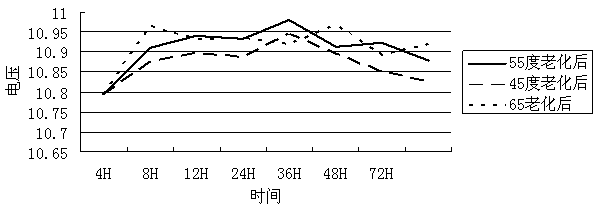

[0030] Step 1. Set the aging temperature of the electronic components to 45°C, 55°C, and 65°C, and the aging time to 4 hours, 8 hours, 12 hours, 24 hours, 36 hours, 48 hours, and 72 hours;

[0031] Step 2. Set the electronic component aging monitoring point, measure and record the representative key parameters of the electronic component after each aging time at each aging temperature;

[0032] Step 3. Use the PPK long-term process capability index to analyze and judge, according to the calculation formula of the PPK long-term process capability index:

[0033] (AVE(M)-LSL(Lower Tolerance)) / 3*Standard Deviation (1)

[0034] (USL(Upper Tolerance) - AVE(M)) / 3*Standard Deviation (2)

[0035] In formula (1) and formula (2): AVE (M) is the average value of all sample data corresponding to the measurement par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com