A kind of igbt drive protection circuit

A technology for driving protection circuits and suppressing circuits, which is applied in the field of converters, can solve the problems of IGBT damage, long delivery period, and poor anti-interference performance, and achieve the effects of simple hardware circuit structure, short pulse suppression, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

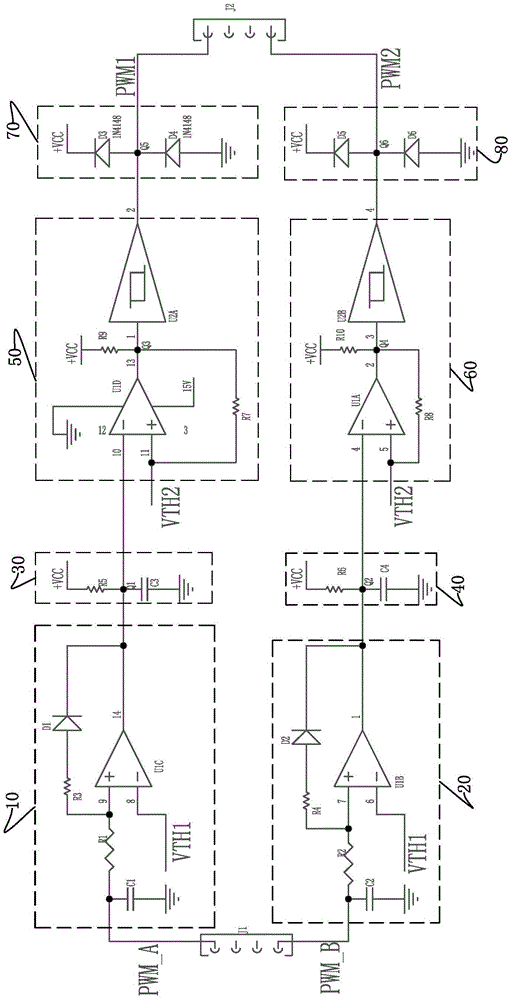

[0032] refer to figure 1 As shown, an IGBT drive protection circuit includes:

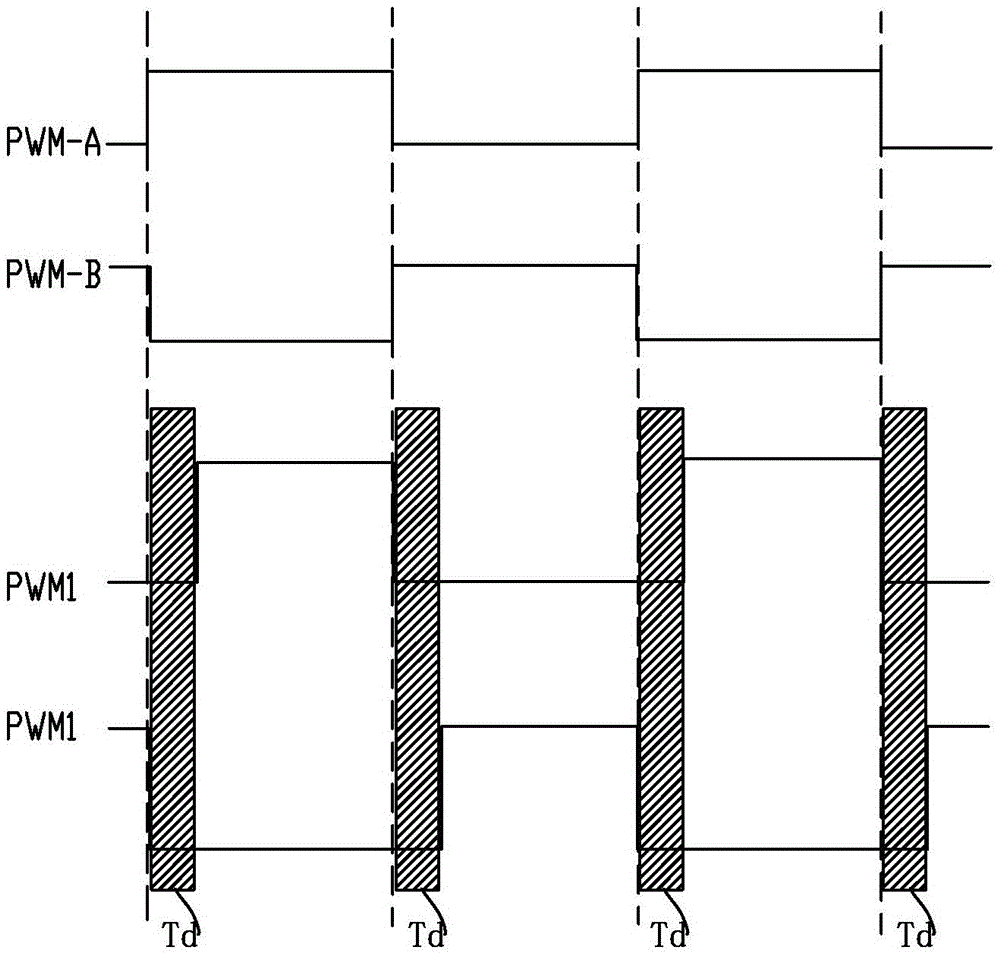

[0033] An input terminal J1, which receives two channels of PWM signals output by an external controller, and the two channels of PWM signals are marked as PWM-A and PWM-B;

[0034] An upper transistor short pulse suppression circuit 10, the upper transistor short pulse suppression circuit 10 includes a first capacitor C1, a first comparator U1C, a third resistor R3, and a first diode D1; one end of the first capacitor C1 is connected to the PWM- A signal terminal, the other end is grounded; the third resistor R3 and the first diode D1 are connected in series between the positive input terminal and the output terminal of the first comparator U1C, and the positive input terminal of the first comparator U1C is connected to the PWM-A signal A first resistor R1 is connected between the terminals, the negative input terminal of the first comparator U1C is the threshold voltage VTH1 input terminal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com