A shockproof safety toy gun

A toy and safety technology, applied in the field of gun making, can solve problems such as insufficient safety, achieve high safety, improve extrusion resistance, and prolong the effect of chemical reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

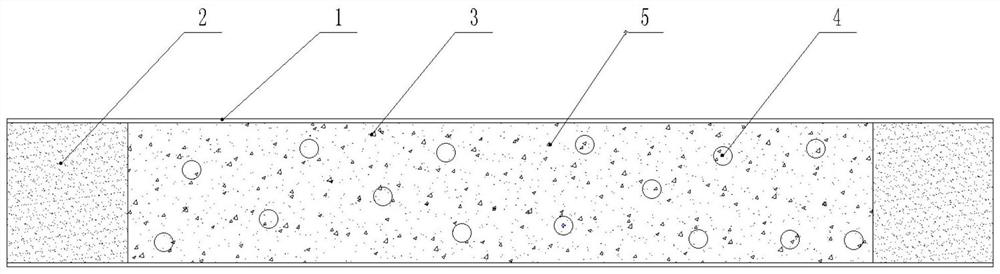

[0047] Embodiment 1: the anti-shock safety toy cannon of the present embodiment comprises wrapping paper tube, immobilizing agent, detonating medicine, sand; The two ends of wrapping paper tube are sealed with immobilizing agent, and the cavity filling that seal forms is filled with detonating medicine that mixes uniformly and sand;

[0048] The detonating medicine includes phosphorus, sulfur, and androsulphur; the total weight of the detonating medicine and the oxidizer in each toy cannon is 0.05 grams, and the weight of the detonating medicine and the oxidizing agent is limited to improve the safety of the toy cannon.

[0049] The particle size of the sand is 1-3mm. The sand includes river sand, angular sand and fuze sand. The ratio of river sand, angular sand and fuze sand is 20:10:1;

[0050] The invention discloses a method for making fuze sand, which comprises the following steps:

[0051] A1: Mix potassium perchlorate, potassium chlorate and potassium manganate powder ...

Embodiment 2

[0068] Embodiment 2: Embodiment 1: the shockproof safety toy cannon of the present embodiment comprises wrapping paper tube, immobilizing agent, detonating medicine, sand; Uniform detonation of drugs and sand;

[0069] The detonating drugs include phosphorus, sulfur, and androsulphur; the total weight of the detonating drugs and the oxidizing agent in each toy gun is 0.045 grams, and the weight of the detonating drugs and the oxidizing agent is limited to improve the safety of the toy gun.

[0070] The particle size of the sand is 1-3mm, and the sand includes river sand, angular sand and fuze sand,

[0071] Preferably; the ratio of river sand, angular sand and fuze sand is 30:15:2 by quantity;

[0072] The invention discloses a method for making fuze sand, which comprises the following steps:

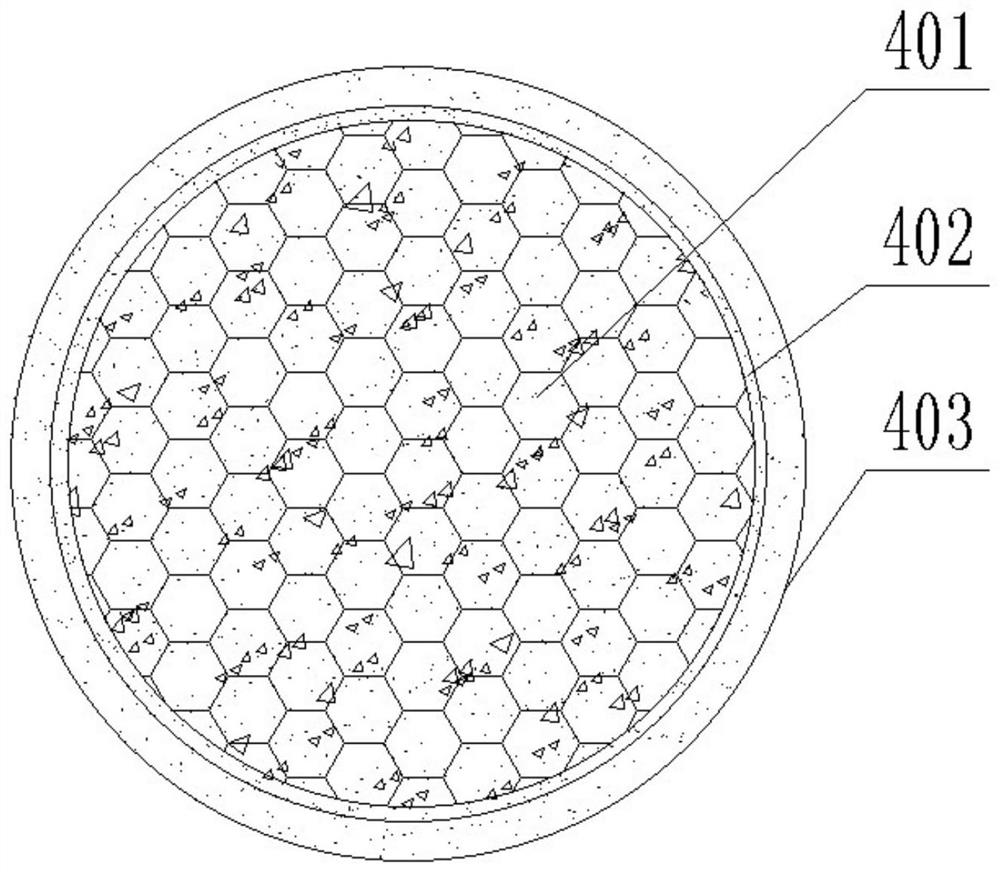

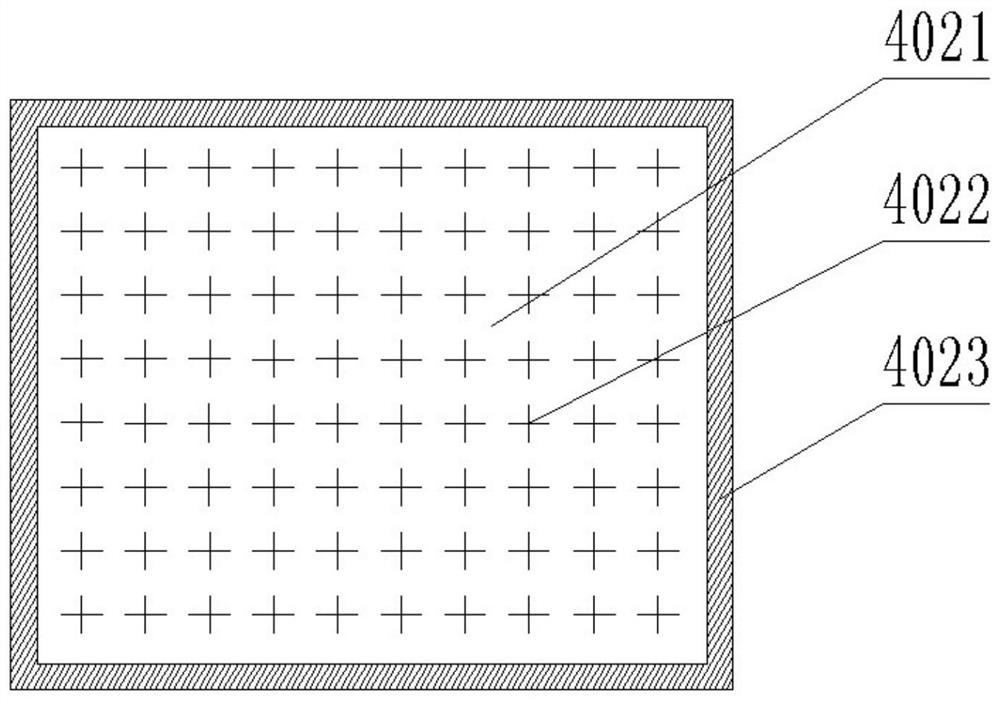

[0073] A1: Mix potassium perchlorate, potassium chlorate and potassium manganate powder evenly; fill in porous sand, and the porous sand is tightly wrapped with composite plant fiber ...

Embodiment 3

[0090] Embodiment 3: Embodiment 1: the anti-shock safety toy cannon of the present embodiment comprises packing paper tube, immobilizing agent, detonating medicine, sand; Uniform detonation of drugs and sand;

[0091] Detonating drugs include phosphorus, sulfur, and androsulphur; the total weight of detonating drugs and oxidizers in each toy gun should not exceed 0.05 grams, and the weight of detonating drugs and oxidants should be limited to improve the safety of toy guns.

[0092] The particle size of the sand is 1-3mm, and the sand includes river sand, angular sand and fuze sand; the ratio of river sand, angular sand and fuze sand is 25:12:1;

[0093] The invention discloses a method for making fuze sand, which comprises the following steps:

[0094] A1: Mix potassium perchlorate, potassium chlorate and potassium manganate powder evenly; fill in porous sand, and the porous sand is tightly wrapped with composite plant fiber paper;

[0095] A2: The outer periphery of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com