LED drive power supply and LED fluorescent lamp

An LED fluorescent lamp and LED driving technology, applied in the direction of electric light source, electric light source, electric lamp circuit layout, etc., can solve the problems of affecting the service life of power supply and LED, reducing product stability and reliability, adverse product quality improvement and automatic production, etc. , to achieve good environmental protection and recycling, easy assembly and maintenance, simple and convenient after-sales service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

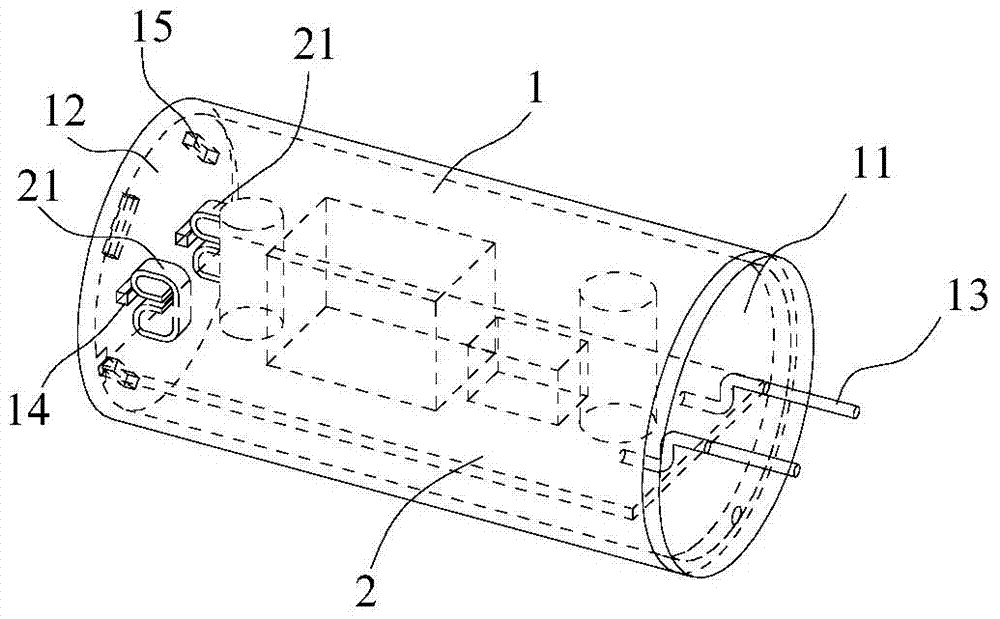

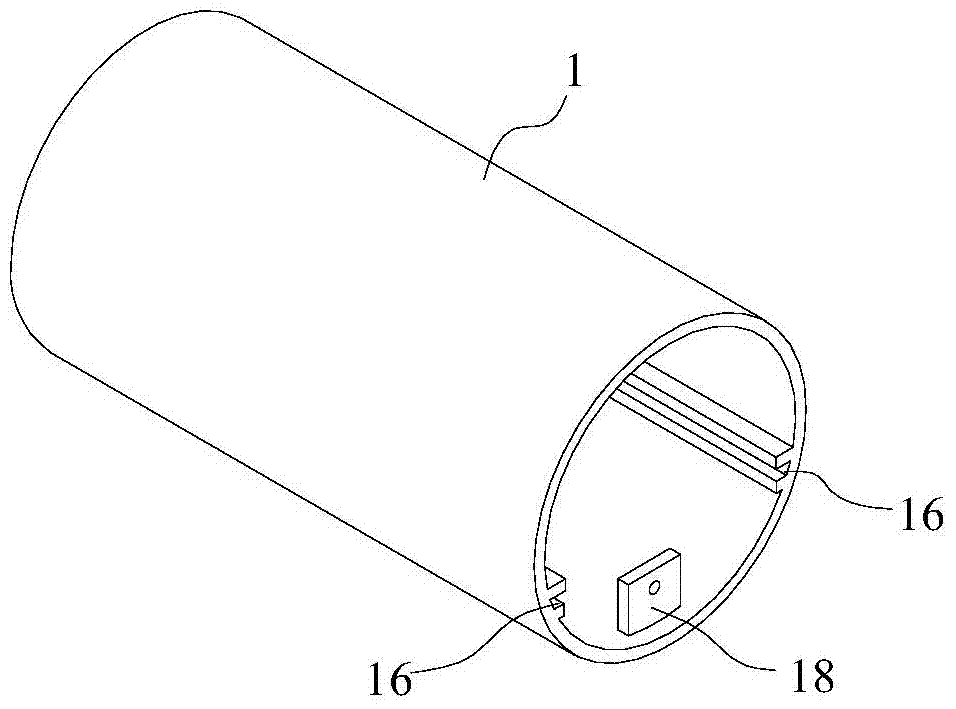

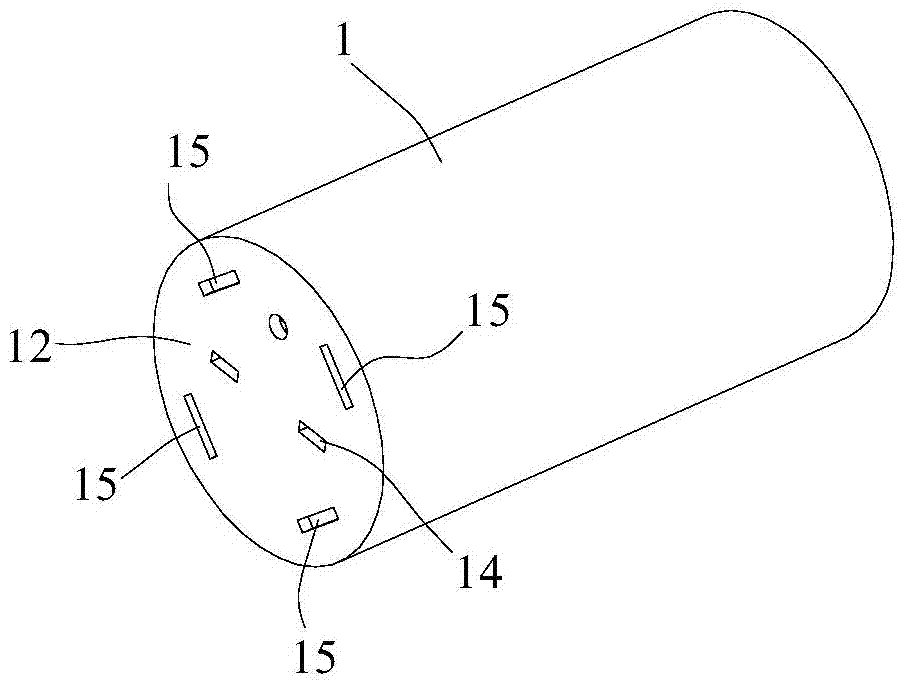

[0029] refer to Figure 1 to Figure 9 , the present invention provides an LED driving power supply, including a cylindrical casing 1, a rectifier circuit board 2 arranged in the casing 1, and a front end cover 11 and a rear end cover 12 that close the casing 1. The front end cover 11 leads out Two circular pins 13 connected to the rectifier circuit board 2, the rear end of the rectifier circuit board 2 is provided with two output contact card slots 21, and the rear end cover 12 is provided with two opposite output contact card slots The socket 14 of 21, the rear end cover 12 is provided with a plurality of connecting holes 15 around the socket 14, and the socket 14 and the connecting holes 15 are both square. Two opposite chute 16 are provided along the inner wall of the housing 1 . The rectifier circuit 2 board is embedded in the chute 16 and is clamped and fixed by the front end cover 11 and the rear end cover 12 .

[0030] The cover 1 and the rear end cover 12 are integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com