metal bead gasket

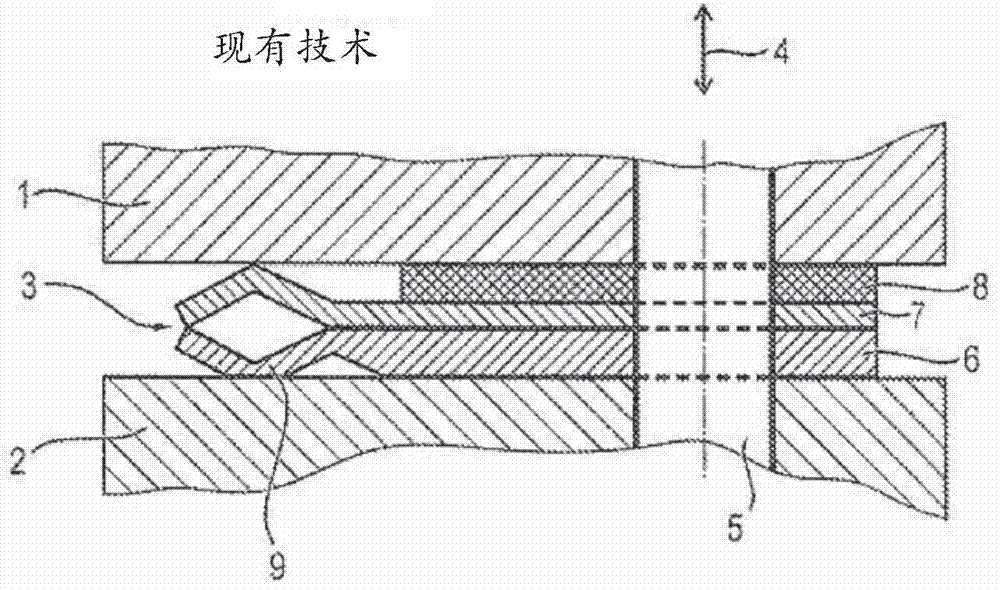

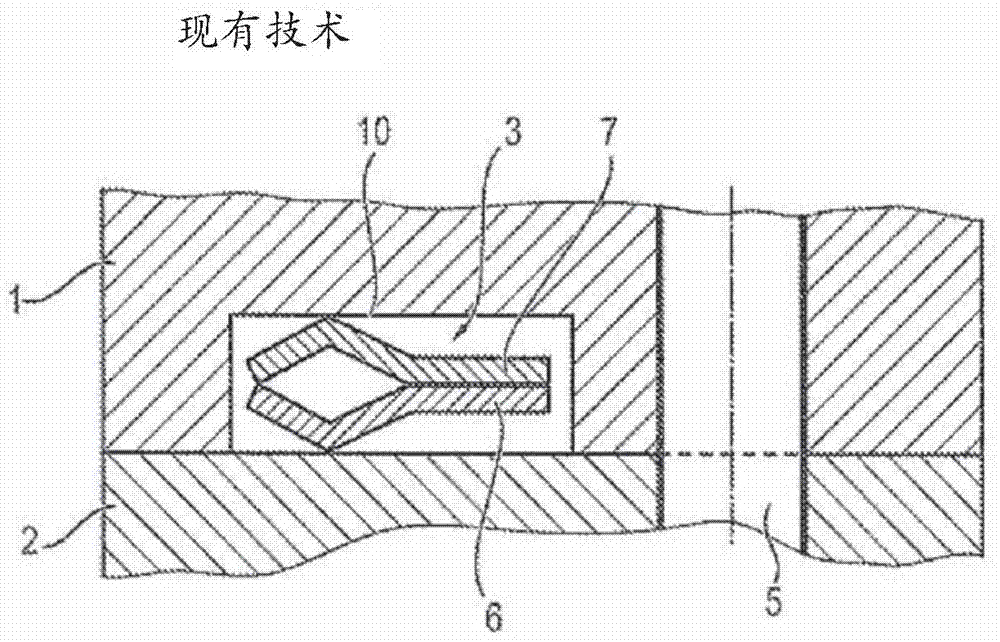

A metal bead and gasket technology, applied in the direction of engine sealing, engine sealing device, machine/engine, etc., can solve the problems of complex and expensive machining of the first element 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

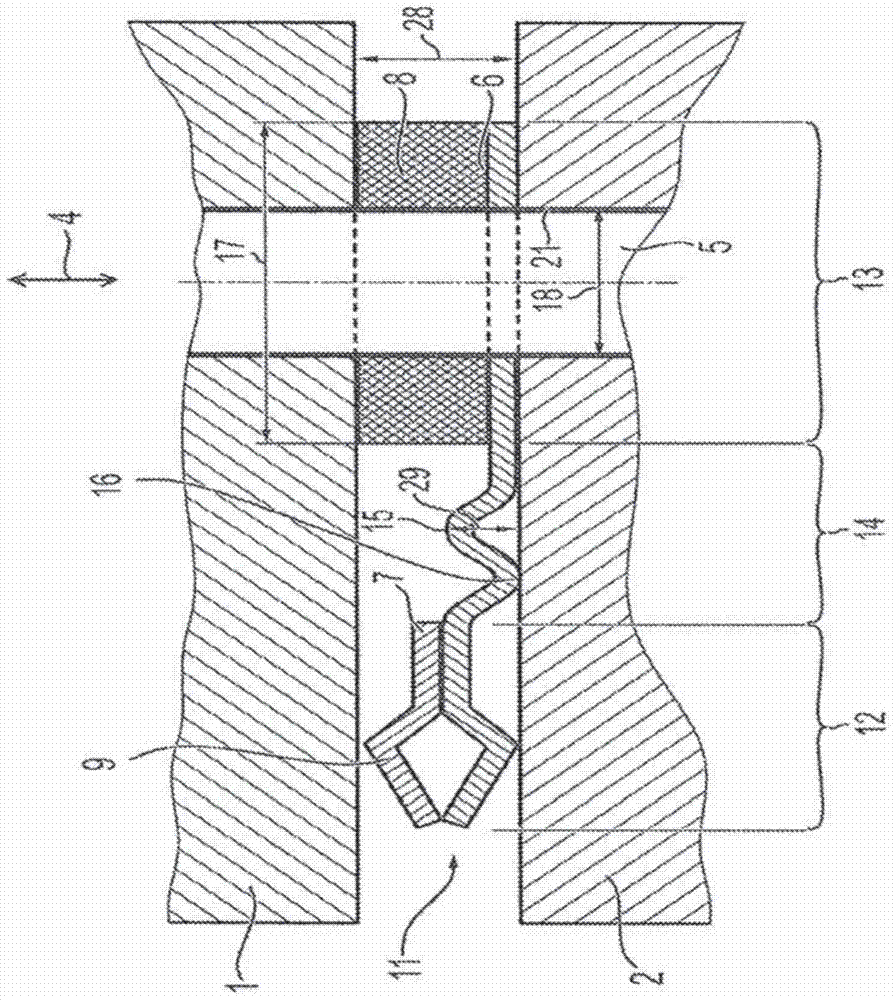

[0025] reference below Figures 3 to 5 Several exemplary embodiments of the present invention are explained in detail.

[0026] image 3 The metal bead gasket 11 is shown in the installed state between a first element 1 and a second element 2 . The metal bead gasket 11 seals the opposing faces of the first and second elements 1, 2 to each other.

[0027] The two elements 1 , 2 are pressed together via a connecting means 5 formed as a screw. The connecting device 5 extends in the supporting direction 4 . A recess 21 formed as a through hole is provided in the metal bead pad 11 . The connection means 5 extend through this recess 21 from the first element 1 to the second element 2 .

[0028] In a direction perpendicular to the supporting direction 4 , the metal bead gasket 11 is divided into a sealing area 12 , a supporting area 13 and an intermediate area 14 . This intermediate region 14 is located between the sealing region 12 and the support region 13 . The sealing area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com