Spark plug for removing residual exhaust gas and associated combustion chamber

A technology of spark plug and pre-combustion chamber, applied in the field of fuel ignition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Reference throughout this specification to "one embodiment," "an embodiment," or similar language means that a particular feature, structure, or characteristic described in connection with the embodiment is included in at least one embodiment. Thus, appearances of "in one embodiment," "in an embodiment," and similar phrases throughout this specification may, but do not necessarily, all refer to the same embodiment.

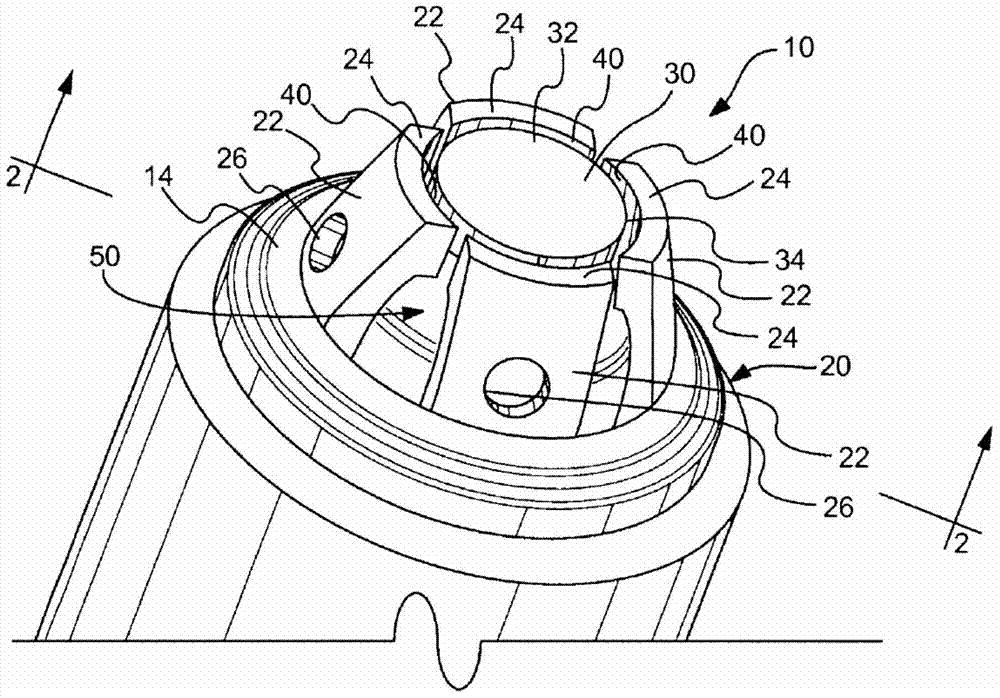

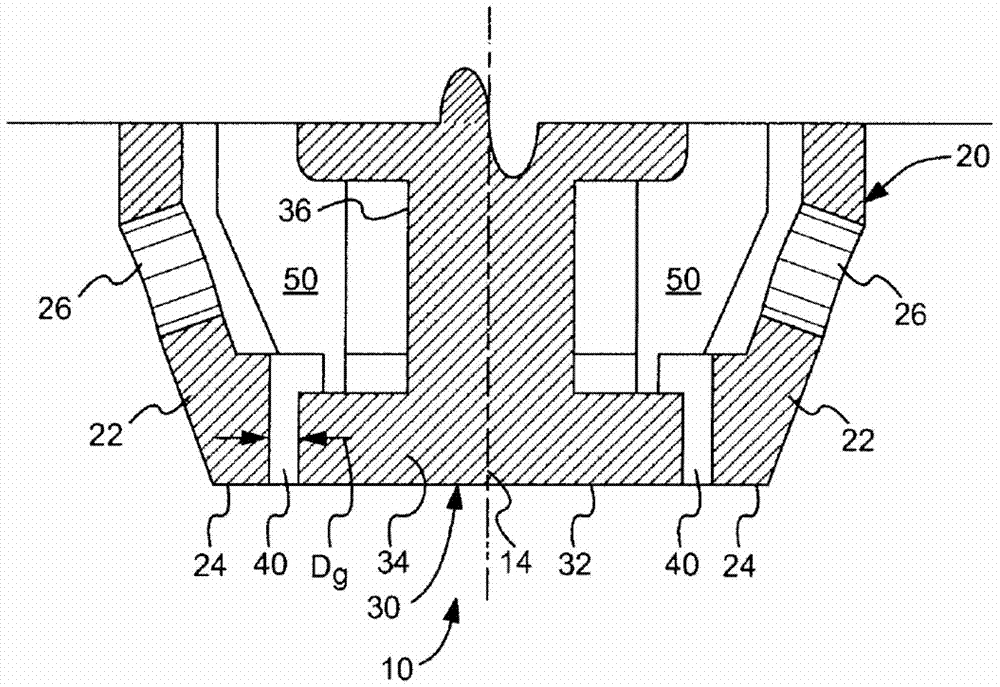

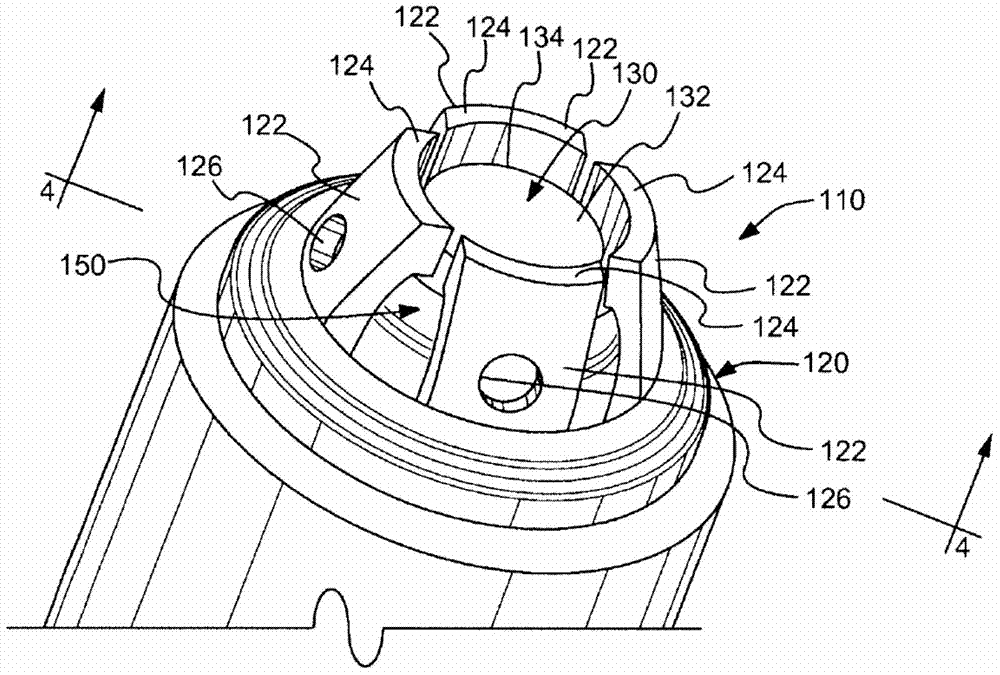

[0035] refer to figure 1 and figure 2 , shows a spark plug 10 according to one embodiment, comprising an outer ground electrode portion 20 with a plurality of outer ground electrodes 22 . The external ground electrode 22 may be defined as an external anode or anode electrode. The spark plug 10 may further include a central cathode electrode 30 around which the outer ground electrode 22 is located. Generally, the outer electrode 22 partially surrounds the central electrode 30 at least laterally or lies laterally around the central electrode 30 . In othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com