A reciprocating self-propelled mechanical manure scraper

A self-propelled, mechanical technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of poor flexibility, single use effect, low work efficiency, etc., and achieve simple structure, convenient operation, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

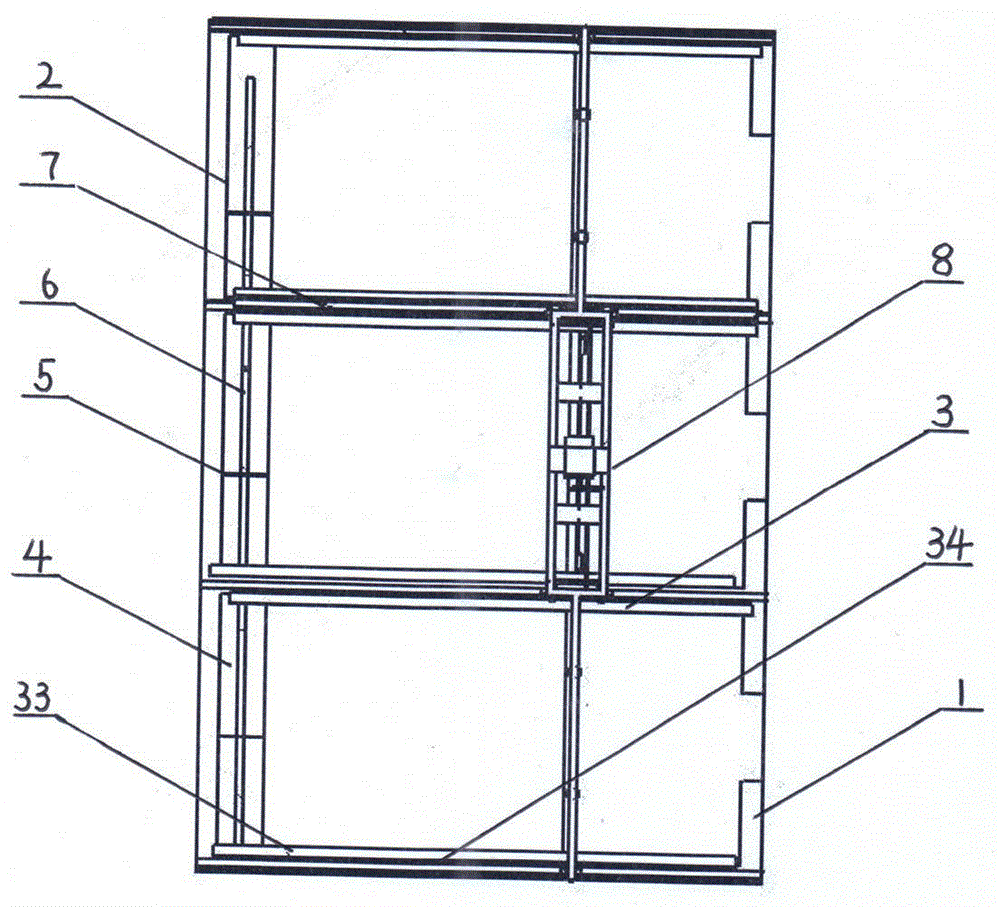

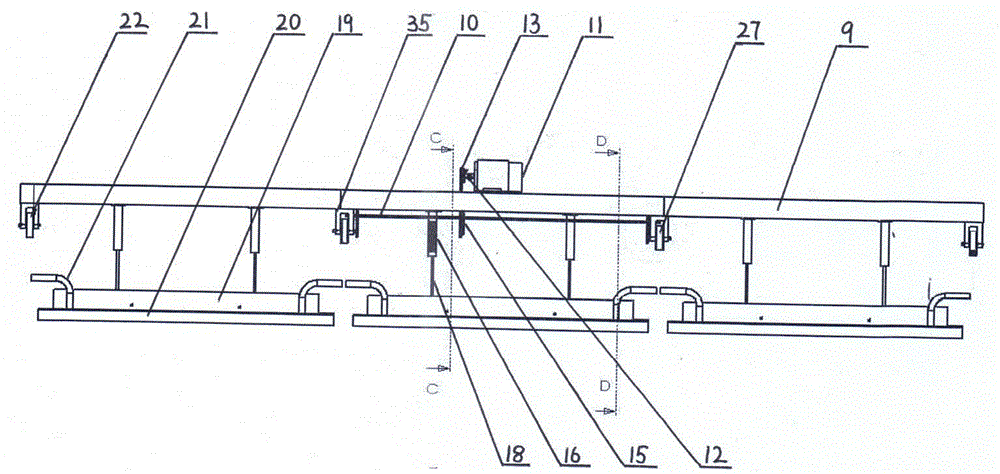

[0022] Such as figure 1 and figure 2 As shown, the excrement cleaning machine 8 of the present invention runs between the front wall 1 and the rear wall 2 along the track on the upper end surface of the two partitions 3 or the partition and the side wall 33, wherein the floor at the lower end of the rear wall is provided with a defecation ditch.

[0023] The present invention can choose to install different numbers of scraper seats according to the cleaning needs to be used for scraping and cleaning the feces in different fences. When a fence is formed between the walls), you only need to install a scraper group at the lower end of the frame corresponding to the fence; if you want to clean the fences of multiple pigpens, install 2~ 3 scraper groups, so that each scraper group is connected side by side to the lower end of the frame, and it can be cleaned.

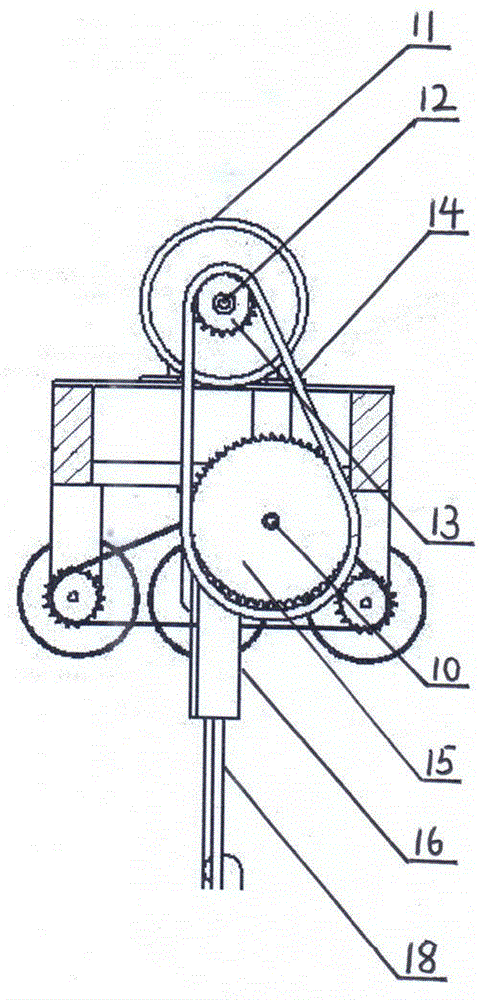

[0024] A reciprocating self-propelled mechanical manure scraper is mainly composed of a mobile platform, a driving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com