A grinding roller removal mechanism of a pulverizer

A technology of milling machine and grinding roller, which is applied in the direction of grain processing, etc., and can solve the problems of heavy disassembly workload, affecting production, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

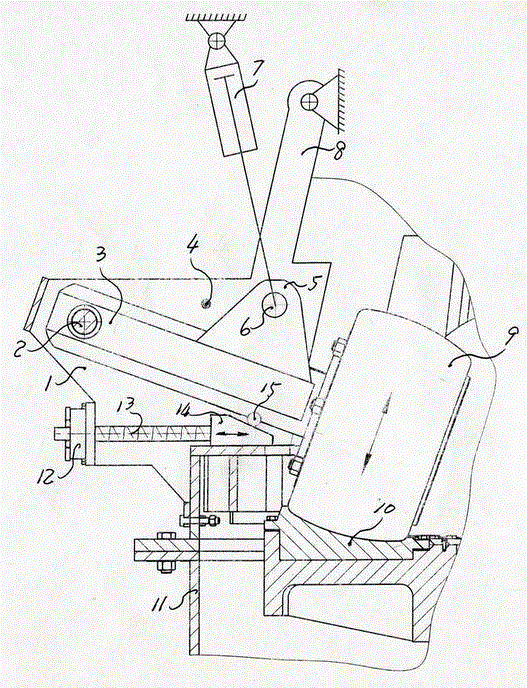

[0008] The present invention has the following embodiments, each grinding roller 9 has a cantilever shaft 3, the outer end of the cantilever shaft is hinged with the pin shaft 2 fixed on the grinding roller bracket 1, and a limit position is fixed on the grinding roller bracket above the cantilever shaft The shaft 4 is opposite to the above-mentioned cantilever shaft, and the upper side of the above-mentioned cantilever shaft is provided with an outwardly protruding ear plate 5, and the piston rod of the hydraulic cylinder 7 fixed on the frame 11 is hinged to the pin shaft 6 on the above-mentioned ear plate. The pendulum plate 8 on the support top is hinged with the pin on the frame.

[0009] The slide block 14 is slidably supported on the guide rail of the frame, the upper end surface of the slide block has an inclined surface, the roller bar 15 is supported between the above-mentioned cantilever shaft and the inclined surface of the slide block, and one end of the screw rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com