Transmission device for conical press

A transmission and cone technology, applied in other household appliances, household appliances, metal processing equipment, etc., can solve the problems of low efficiency, waste, large errors, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

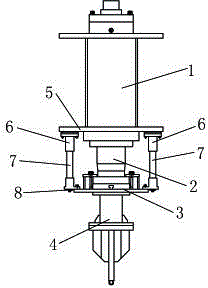

[0011] Combine below figure 1 Specific description embodiment:

[0012] A kind of transmission device of conical press, it is characterized in that, the transmission device of described conical press comprises hydraulic oil cylinder 1, and the output end of described hydraulic oil cylinder 1 is connected with output shaft 2, and described output shaft 2 The lower end of the connection seat 3 is welded, the bottom of the connection seat 3 is connected with a conical die 4, the conical die 4 is separable from the connection seat 3, and the conical die 4 is hydraulically Under the promotion of oil cylinder 1, it can move up and down in the vertical direction. The outer wall of the hydraulic cylinder 1 is provided with a fixed plate 5, and the fixed plate 5 is fixed with two sliding sleeves 6, and the two sliding sleeves 6 are located on the corresponding sides of the hydraulic cylinder 1. The sliding sleeve 6 is provided with a sliding rod 7 that can slide up and down in the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com