A monitoring system for ladle rotary table of continuous casting machine

A large-bag turntable and monitoring system technology is applied in the field of large-bag turntable monitoring systems for continuous casting machines, and can solve problems such as hidden dangers in production safety, crushed nylon cages, and inability to accurately determine working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

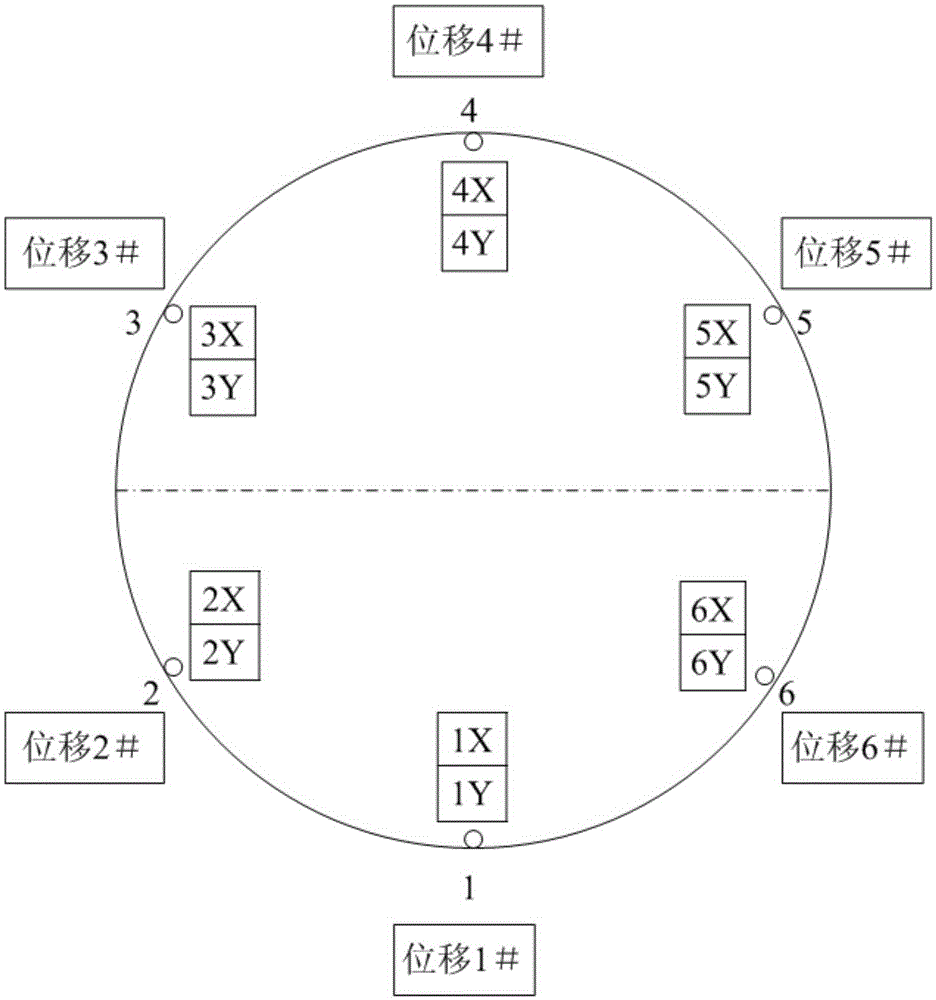

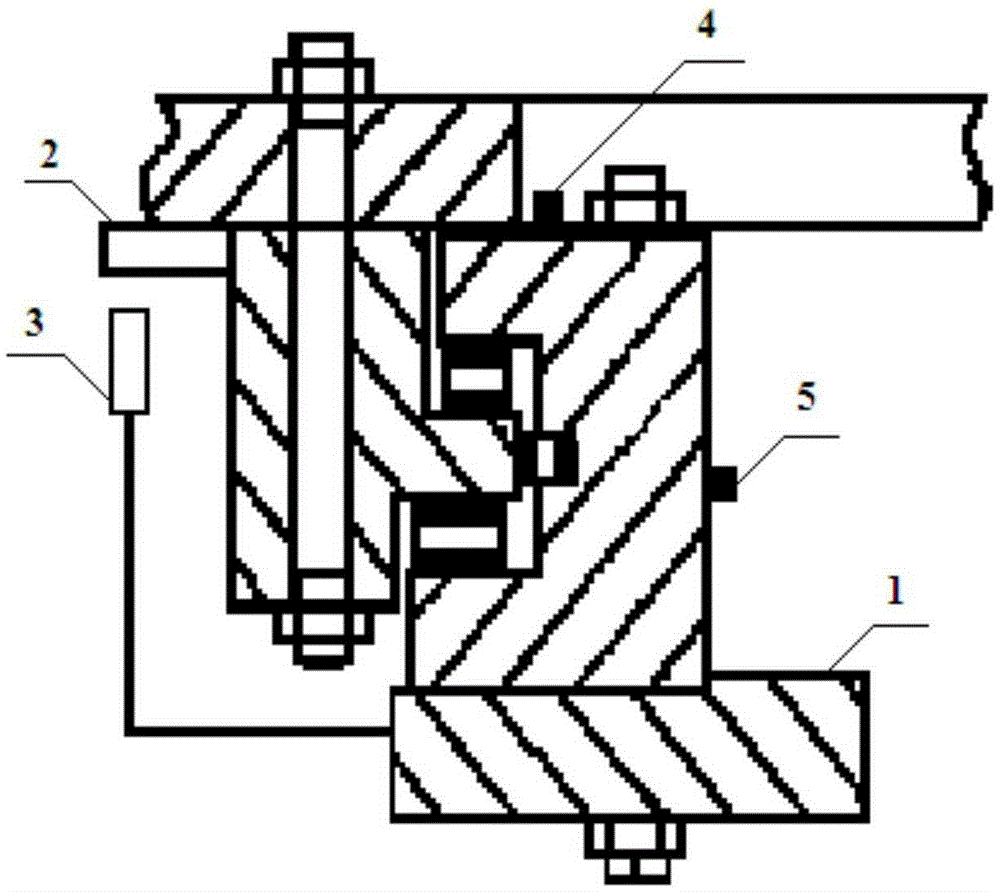

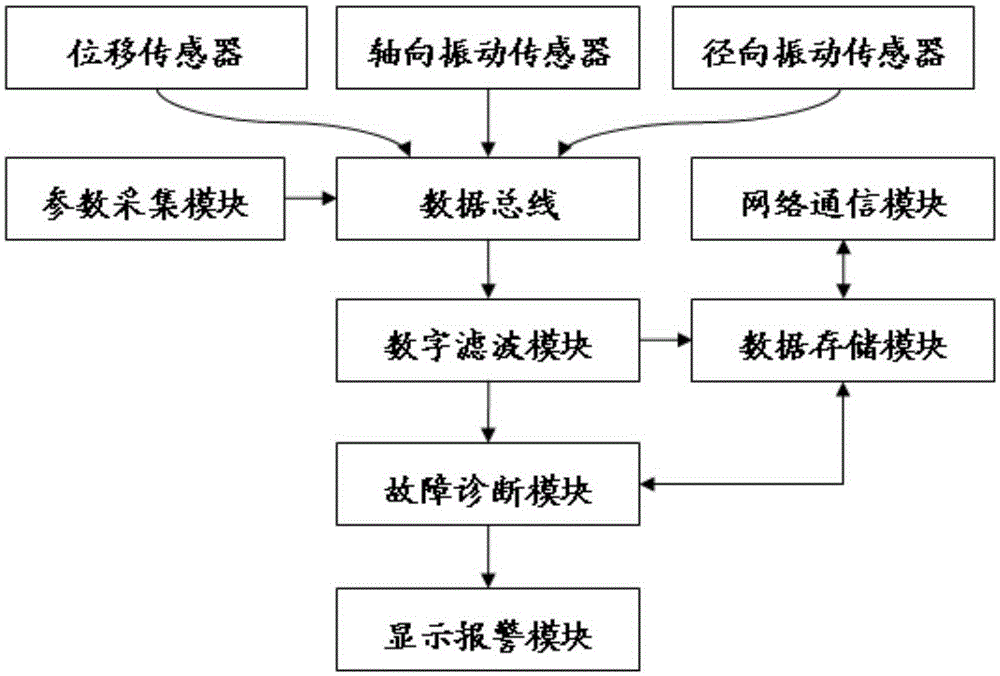

[0020] see figure 1 , the continuous casting machine ladle turret monitoring system provided by the embodiment of the present invention is characterized in that it includes: a vibration monitoring unit, a displacement monitoring unit, a communication bus, an industrial computer, and an audible and visual alarm; the vibration detection unit includes: a plurality of vibration Sensor group; multiple vibration sensor groups are arranged around the rotating tower bearing of the continuous casting machine to form multiple state monitoring points (1~6); the displacement monitoring unit includes: multiple displacement sensors; one is set at any state monitoring point Displacement sensor; the vibration sensor and displacement sensor at any state monitoring point are connected to the industrial computer through the communication bus, and the monitored vibration parameters and displacement parameters are sent to the industrial computer; the safety warning threshold of the preset vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com