A manufacturing process of a microporous wire drawing die cemented carbide core

A cemented carbide and manufacturing process technology, which is applied in the field of manufacturing process of microporous wire drawing die cemented carbide core, can solve the problems of difficult forming, difficult product forming, high material requirements, etc., and achieve good air quality and flexible product aperture , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

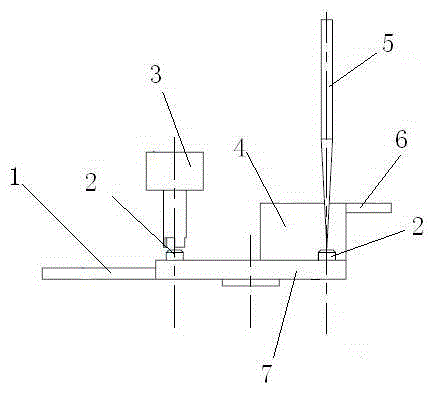

[0023] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0024] like figure 1 As shown, the present invention works and is implemented in this way, and is characterized in that the method steps are as follows:

[0025] 1. Ingredients: 0.3um ultra-fine-grained WC powder is used as the main material, and the content of the added Co powder is controlled at 5-8%, so that after the raw materials are ground with alcohol and spray-dried, the hardness of the resulting mixture, that is, the HRA value 90 to 95, so that the wear resistance of the wire drawing die material meets the needs of production;

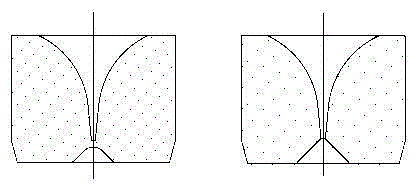

[0026] 2. Molding, the mixture is then molded by a mechanical powder molding press. In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com