Method and device for sleeving central air-conditioning capillary tube with heat shrink tube

A central air-conditioning and capillary technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low work efficiency, high labor intensity, poor consistency of casing position, etc., to achieve simple action and reduce labor intensity. , good effect of casing position consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

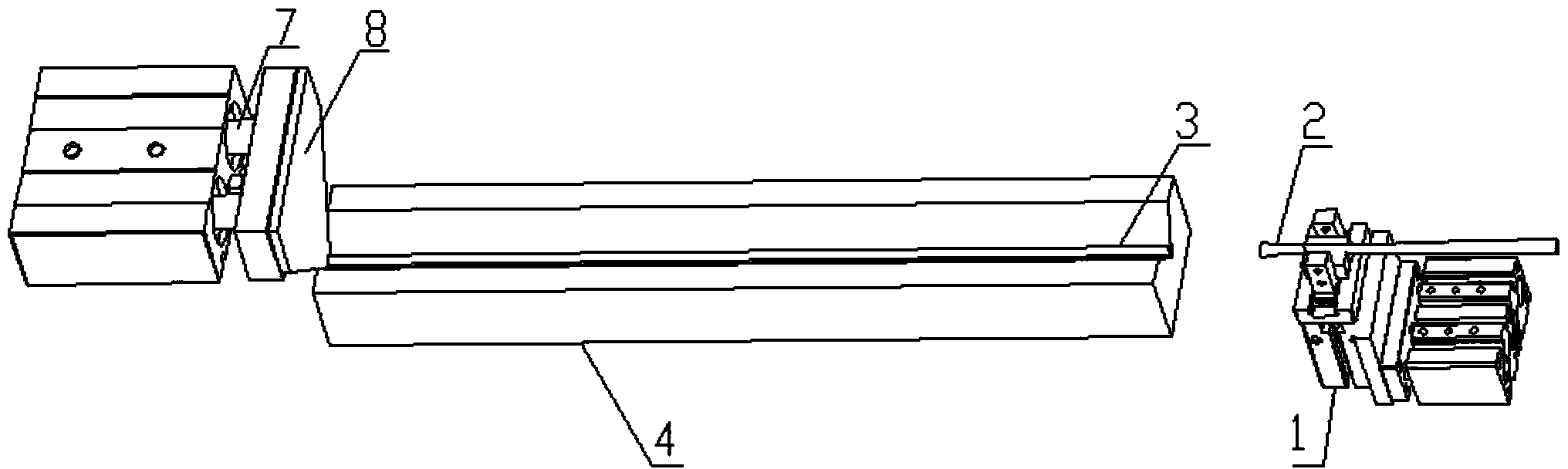

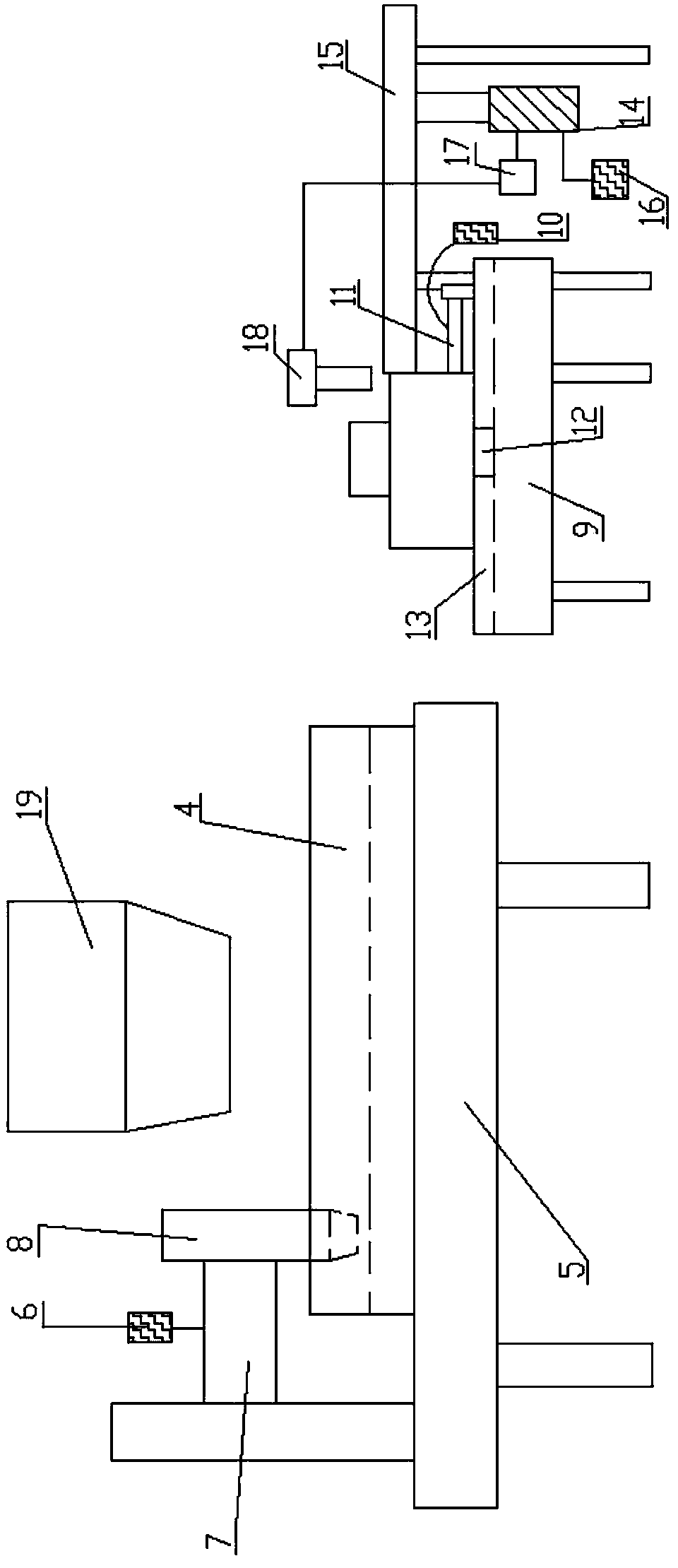

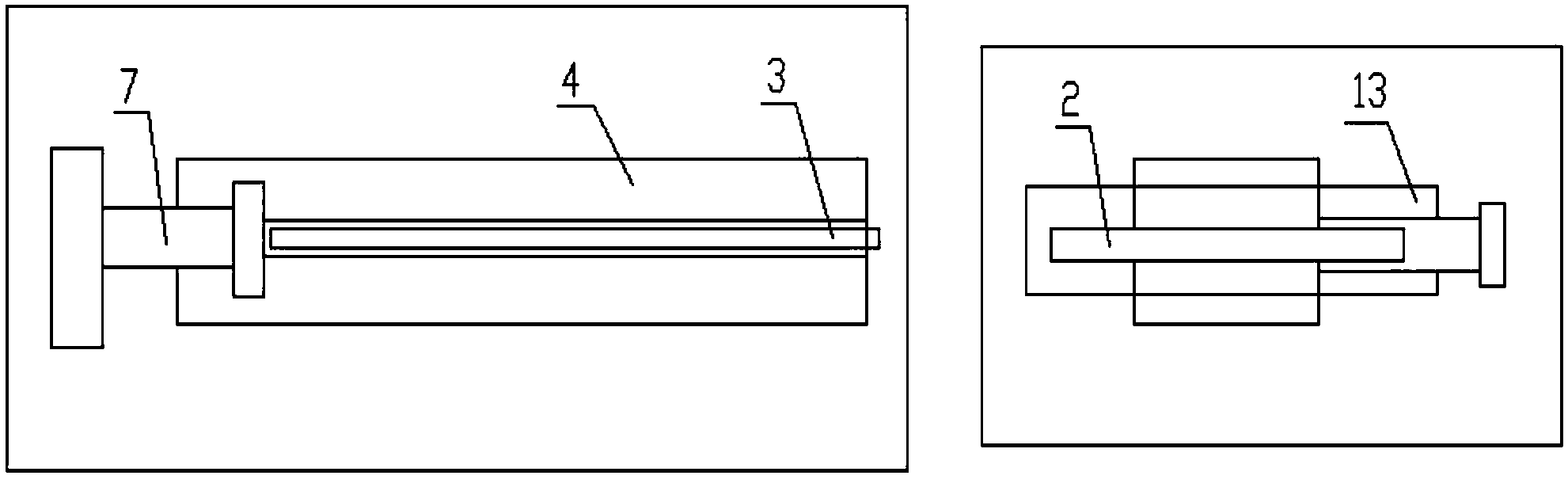

[0031] combine figure 1 , figure 2 , image 3 , a method for covering heat-shrinkable tubes on central air-conditioning capillary tubes, comprising the following steps:

[0032] (1) Clamp the outer surface of one end of the heat-shrinkable tube 2 with the clamp 1; the heat-shrinkable tube 2 can be firmly restrained. During the process of inserting the capillary 3 into the heat-shrinkable tube 2, the friction between the capillary 3 and the heat-shrinkable tube 2 It will not cause the heat-shrinkable tube 2 to move, which solves the problem of automatically placing the capillary 3 on the designated position of the soft heat-shrinkable tube;

[0033] (2) Place the capillary 3 on the V-shaped track 4 so that the center of the capillary 3 is aligned with the center of the heat-shrinkable tube 2;

[0034] (3) Use the first driving device to drive the capillary 3 to move toward the clamp 1 , and insert the capillary 3 into the heat shrinkable tube 2 .

[0035] A device for putt...

Embodiment 2

[0043] combine figure 1 , figure 2 , Figure 4 , a method for covering heat-shrinkable tubes on central air-conditioning capillary tubes, comprising the following steps:

[0044] (1) Clamp the outer surface of one end of the heat-shrinkable tube 2 with the clamp 1; the heat-shrinkable tube 2 can be firmly restrained. During the process of inserting the capillary 3 into the heat-shrinkable tube 2, the friction between the capillary 3 and the heat-shrinkable tube 2 It will not cause the heat-shrinkable tube 2 to move, which solves the problem of automatically placing the capillary 3 on the designated position of the soft heat-shrinkable tube;

[0045] (2) Place the capillary 3 on the V-shaped track 4 so that the center of the capillary 3 is aligned with the center of the heat-shrinkable tube 2;

[0046] (3) Use the first driving device to drive the capillary 3 to move toward the clamp 1 , and insert the capillary 3 into the heat shrinkable tube 2 .

[0047] A device for put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com