Portable mobile small 3D printer

A 3D printer and mobile technology, applied in the field of rapid prototyping, can solve the problems of complex mechanical device structure, inability to carry, and large overall volume, and achieve the effect of simple door lock mechanism, ingenious structural design, and compact structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical contents of the present invention are further explained in detail below in conjunction with examples.

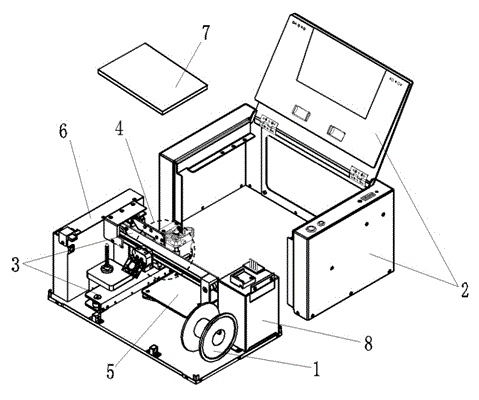

[0032] like figure 1 Shown is an exploded schematic view of the portable mobile 3D printer of the present invention. In this embodiment, a portable mobile 3D printer includes: a storage device 1 , a casing 2 , a transmission device 3 , a discharge device 4 , a printing table 5 , a control box 6 , a manipulation device 7 and a power supply 8 .

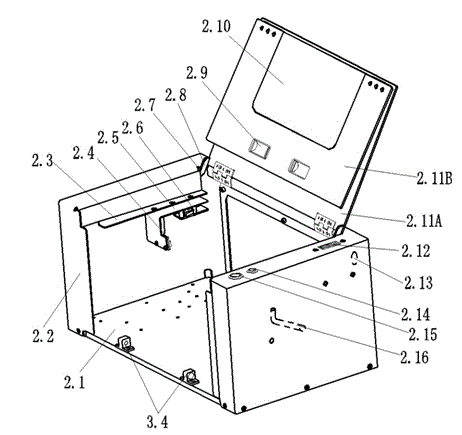

[0033] to combine figure 2 and Figure 10 , it can be clearly seen that the housing 2 includes a base plate 2.1, a housing frame 2.2, and a folding upper cover 2.11, the housing frame 2.2 is connected to the base plate 2.1 through a screw group, and the folding upper cover 2.11 is connected to the housing frame 2.2 through a hinge;

[0034]The folding upper cover 2.11 includes A panel 2.11A and B panel 2.11B, tail hooks 2.8 are provided at the lower corners of the left and right sides of the A panel 2.11A, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com