Automatic pneumatic punching machine

A pneumatic punching machine and automatic technology, applied to punching machines, presses, manufacturing tools, etc., can solve the problems of cost waste, high punching force, and high purchase cost of punching machines, and achieve the effects of reducing production costs, low cost, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

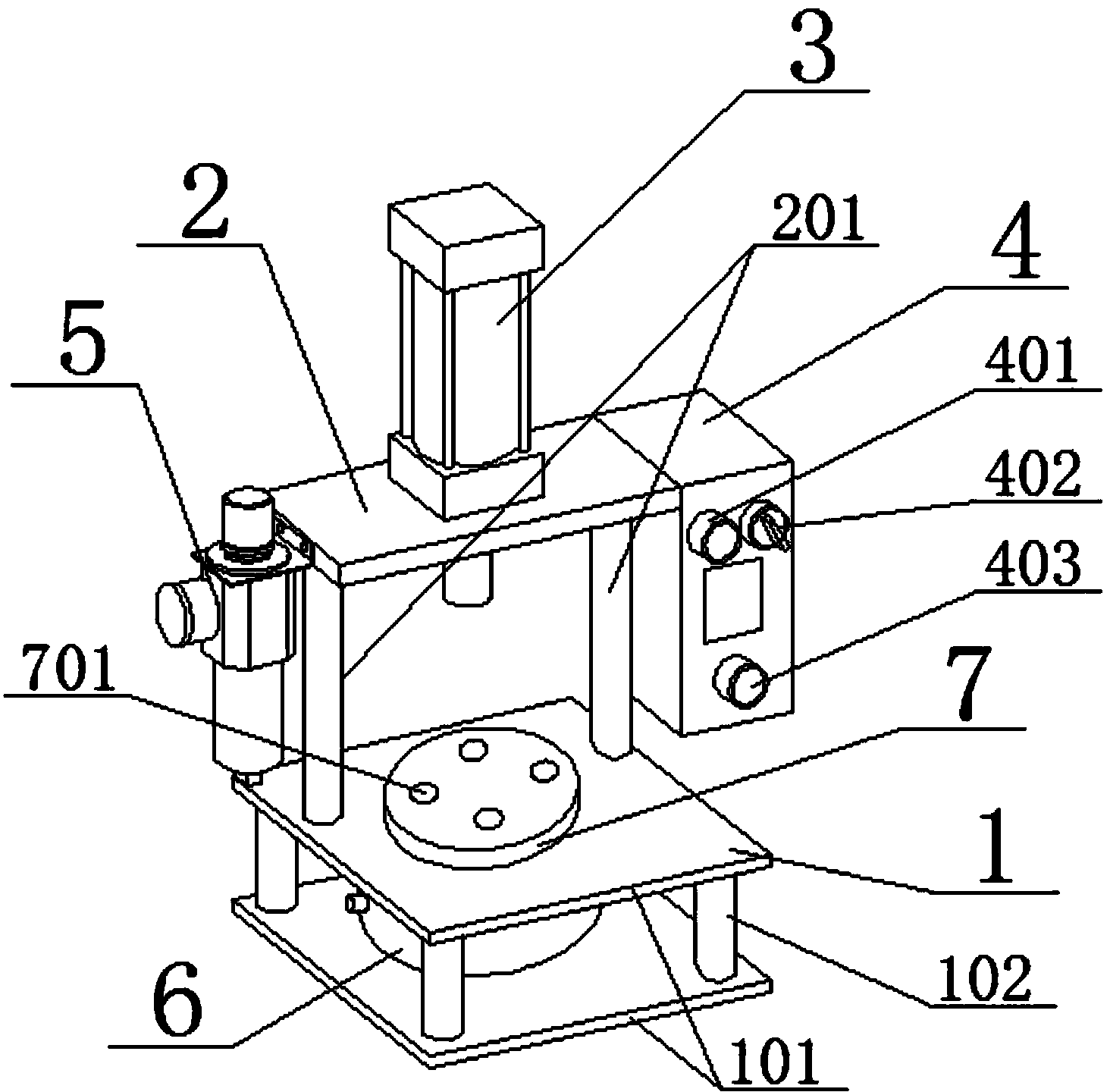

[0014] Referring to the accompanying drawings, an automatic pneumatic punching machine includes a base 1, a frame 2, a stamping mechanism 3, a workbench 7 and a control box 4, and is characterized in that: the stamping mechanism 3 is a cylinder, and the cylinder is inverted on the frame 2 On the crossbeam, the base 1 is a sandwich mechanism supported by two metal plates 101 through a number of support rods 102. A rotating cylinder 6 is installed in the middle of the interlayer, and the rotating cylinder 6 is connected to the workbench 7. On the frame 2 An air valve 5 is provided; the frame 2 is installed on the base 1 as a crossbeam through the support rods 201 on both sides; Stop switch 403; the workbench 7 is a circular workbench, and the workbench is provided with some installation holes 701; the two metal plates 101 of the base 1 are square, and the support rods 102 are 4, and the support rods support respectively at the corner of the sheet metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com