Novel self-dumping tractor-semitrailer

A semi-trailer and self-unloading technology, which is applied to vehicles with inclined bearing motion, vehicles with endless chains/belts, etc., can solve the problems of scattered goods, unable to unload goods, and unable to rotate chains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

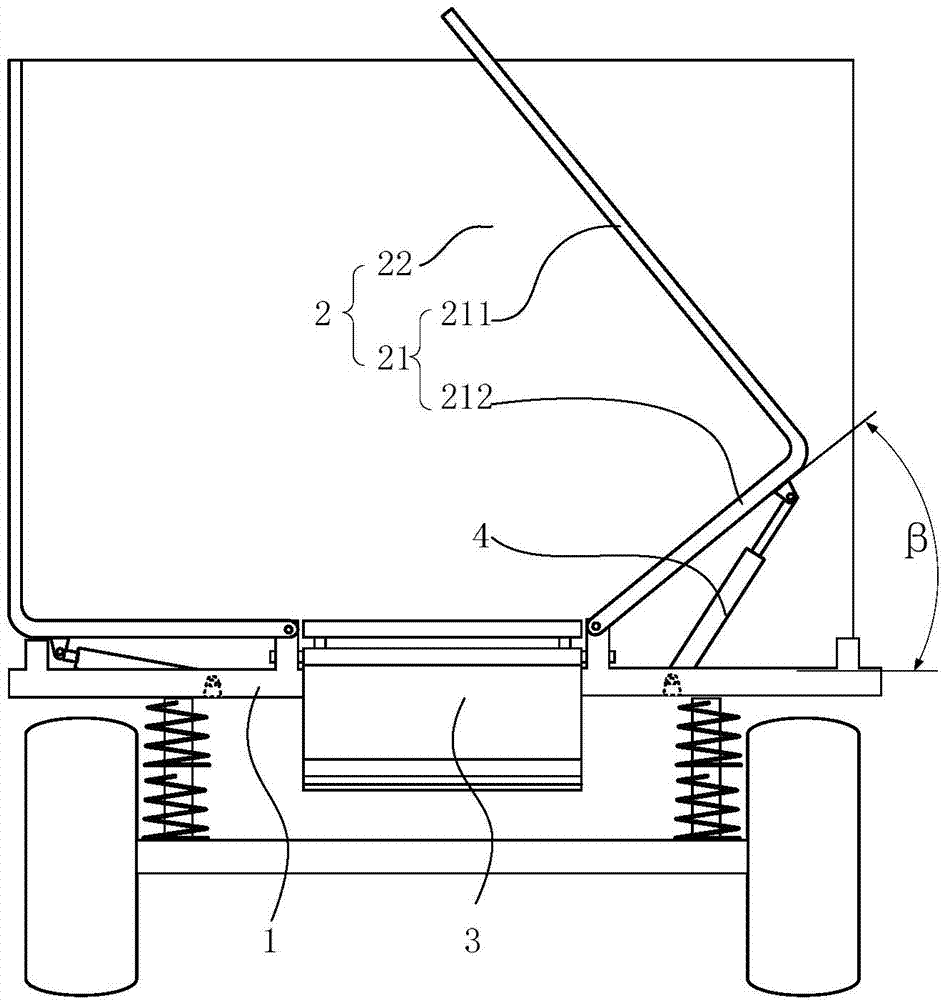

[0026] Example 1, see attached figure 1 , 3 -6.

[0027] A self-unloading semi-trailer with fully reversible left and right side panels of the carriage, comprising a carriage 1, a carriage 2 mounted on the carriage 1, a cargo unloading device 3, and two sets of oil cylinders 4.

[0028] The compartment 2 includes a front baffle 22, a rear upturn door (not shown in the drawings), and two left and right mirror-symmetric L-shaped movable corner panels 21. The L-shaped movable corner panels 21 include movable side panels 211 and The free end of the movable bottom plate 212 is hinged with the frame 1, and one end of the oil cylinder 4 is hinged with the frame 1 and the other end is hinged with the movable bottom plate 212. The front baffle 22 and the rear upturn door are respectively fixed to the frame 1 and cooperate with the L-shaped movable corner plate 21 through manual or automatic locking devices.

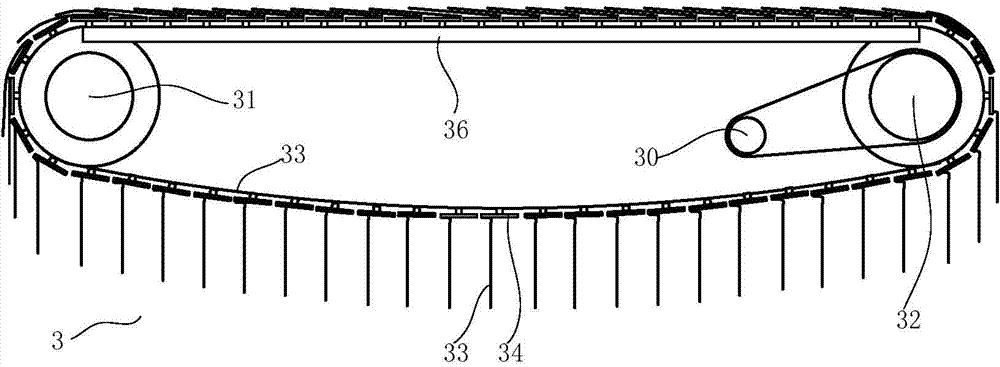

[0029] The unloading device 3 includes a driven sprocket 31 and a driving sprocket ...

Embodiment 2

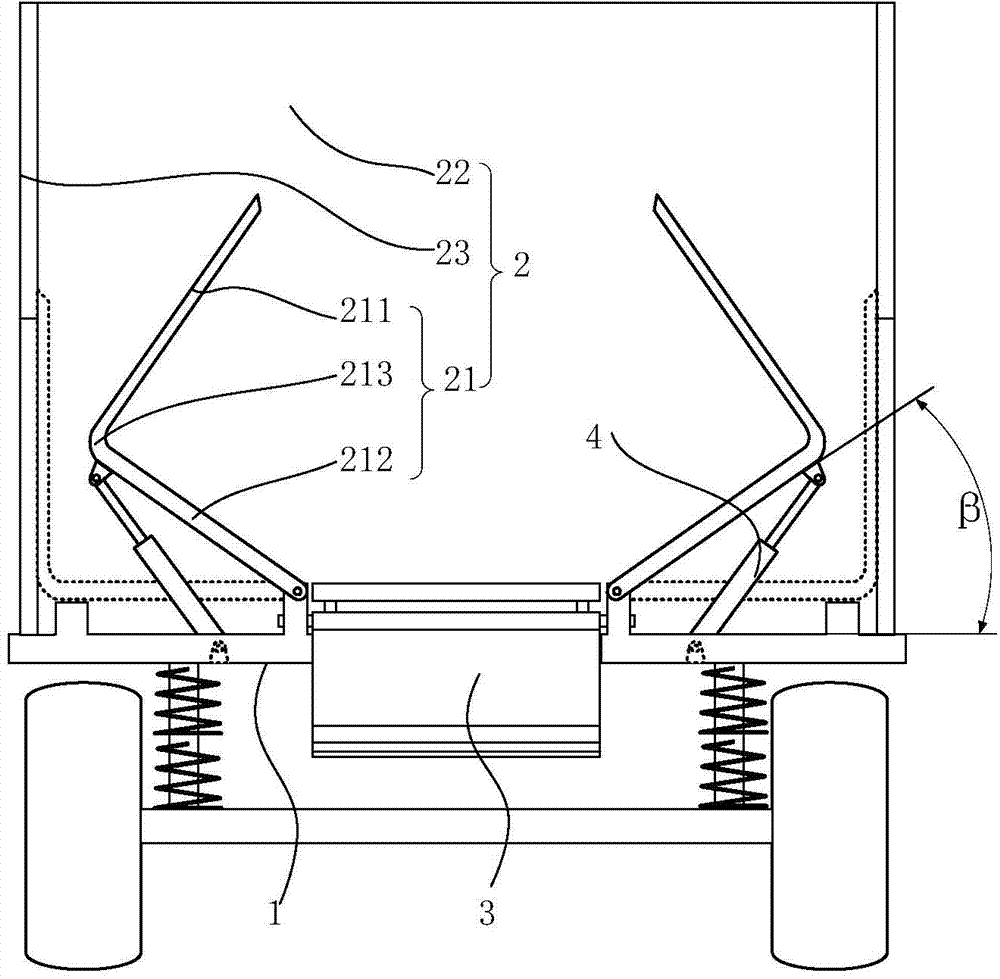

[0035] Example 2, see attached Figure 2-6 .

[0036] A dump semi-trailer in which the left and right side panels of the carriage can be partially reversed. Others are the same as Embodiment 1, but the difference is: the carriage 2 of this kind of dump semi-trailer also includes a fixed side panel 23, which is located in the movable side panel. The outer side of the side plate 211 is respectively fixed with the frame 1 and the front baffle 22, and cooperates with the rear upturn door through a manual or automatic locking device. The height of the movable side plate 211 is 800 cm, and the height of the fixed side plate 23 is 1800 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com