Wastewater anaerobic reaction system for recycling waste heat through heat pipes

An anaerobic reaction and anaerobic reactor technology, which is applied in the field of energy saving and emission reduction, can solve problems such as polluting the environment, and achieve the effects of increasing temperature, improving energy utilization rate, and enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

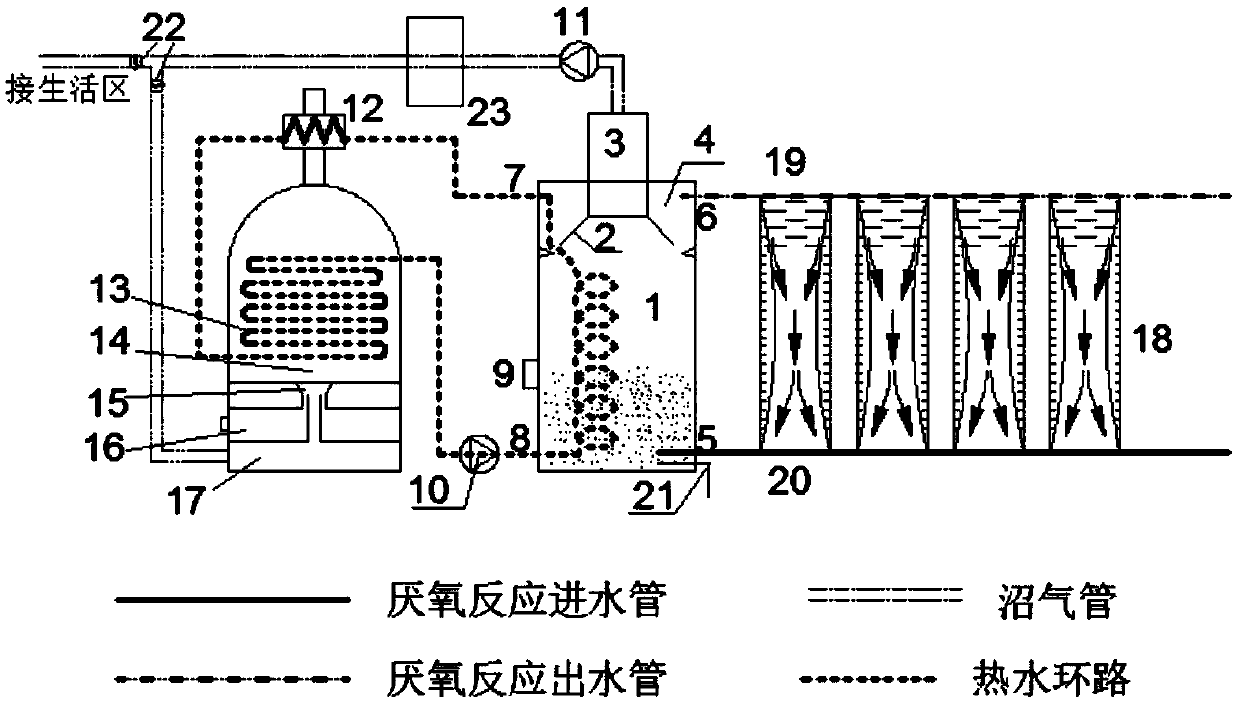

[0016] Such as figure 1 As shown, the upflow anaerobic reactor includes an upflow anaerobic reaction tank 1, and there is a large amount of anaerobic sludge in the sludge reaction zone at the bottom of the reaction tank 1. The anaerobic sludge with good sedimentation performance and coagulation performance is A sludge layer is formed in the lower part. One side of the bottom of the anaerobic sludge layer has a heating water inlet pipe 8, and the other side has an anaerobic reaction inlet pipe 5 and a sludge discharge pipe 21. In the sedimentation area at the top of the upflow anaerobic reaction tank 1 There is an anaerobic reaction outlet pipe 6 on one side of 4, and a heated hot water outlet pipe 7 on the other side; there is also a three-phase separator 2 and a gas collection chamber 3 at the top of the reactor. The sewage to be treated enters the sludge reaction zone in the upflow anaerobic reaction tank 1 from the anaerobic reaction inlet pipe 5, and is fermented by the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com