Hydraulic mechanical drive device for electric vehicle

A technology of hydraulic machinery and transmission devices, which is applied to multi-ratio transmissions, transmissions, fluid transmissions, etc., and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

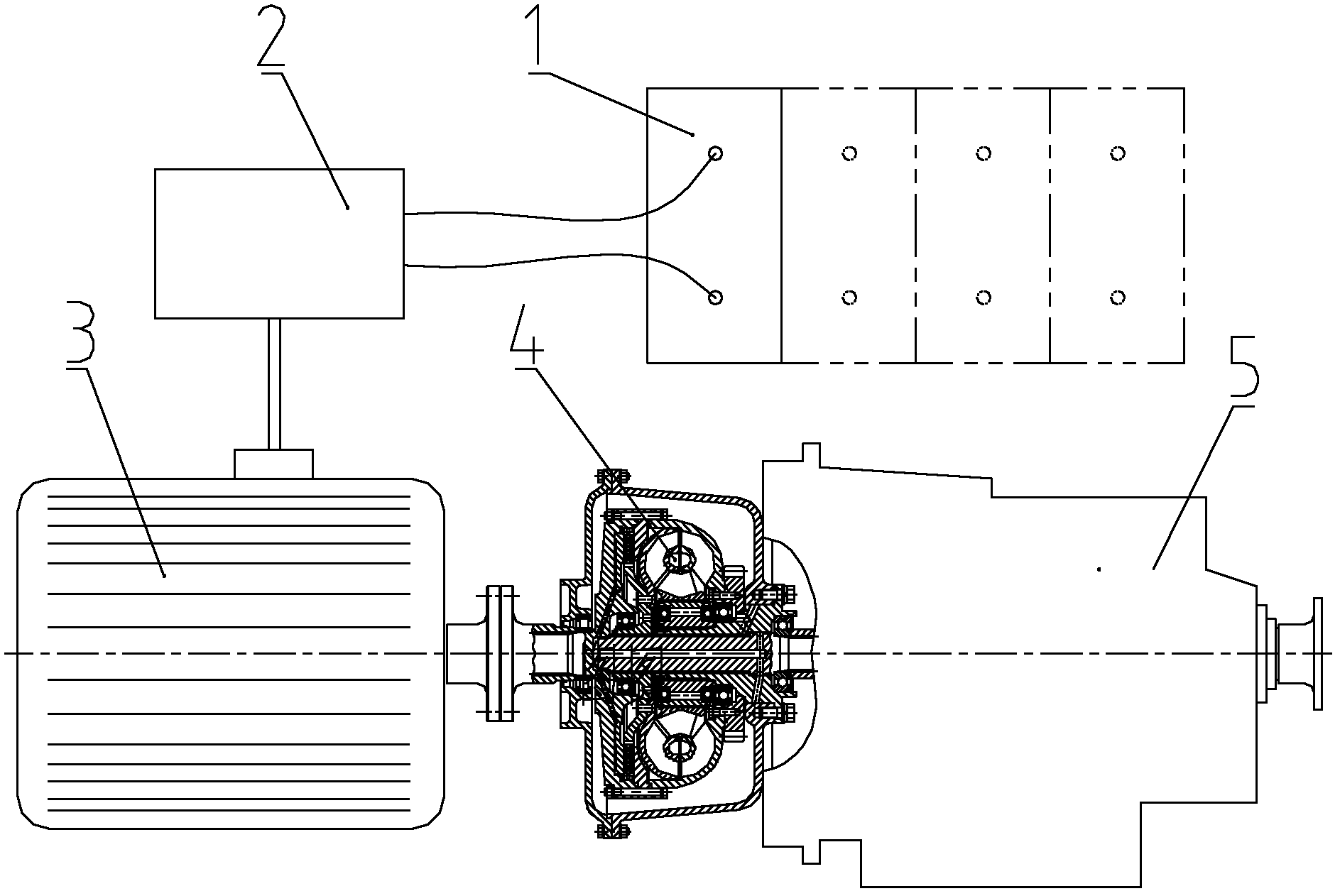

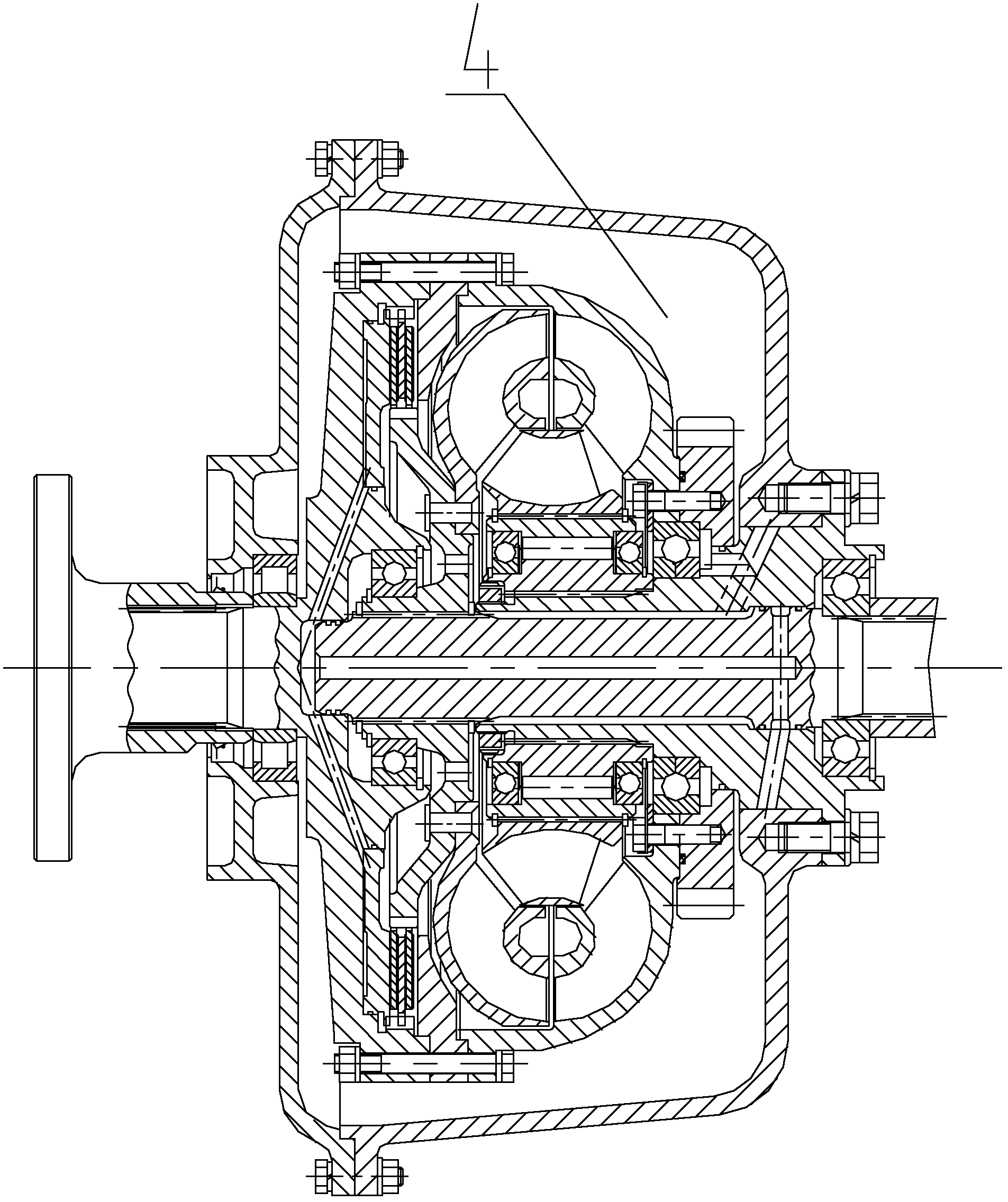

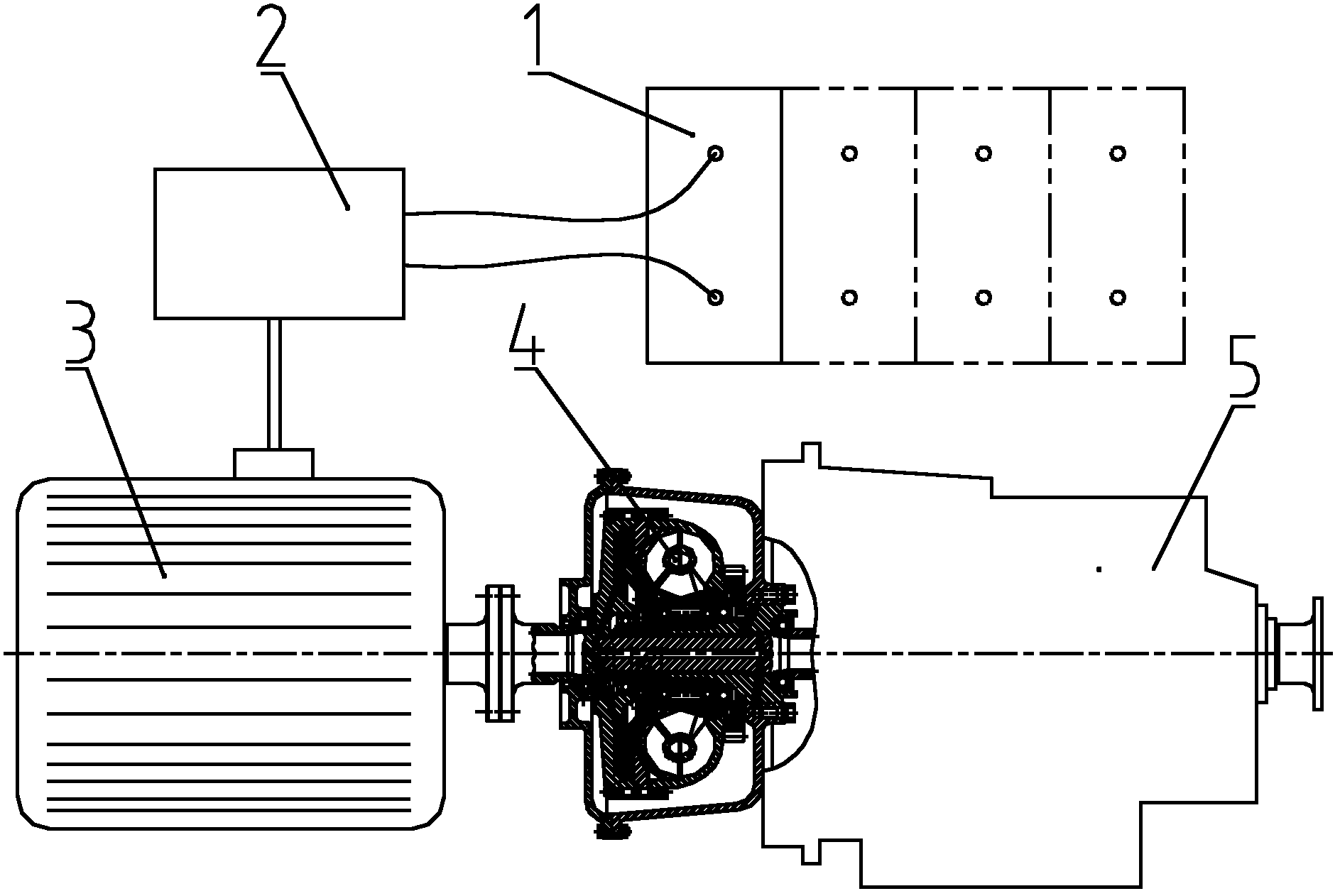

[0021] A hydromechanical transmission device for an electric vehicle, comprising a battery pack 1, a motor 3, a motor controller 2, a comprehensive hydraulic torque converter with a lock-up clutch 4, and a power shift gearbox 5, and the battery pack 1 supplies power to the motor 3. The motor controller 2 controls the motor 3 to drive the integrated torque converter 4 with a lock-up clutch, the integrated torque converter 4 with a lock-up clutch is connected to the power shift gearbox 5, and the power shift gearbox 5 is connected to The driving axle carries out the hydromechanical transmission of the vehicle to realize the walking of the vehicle.

[0022] Typically, motors start on load with very high currents. This necessarily leads to an increase in the number of battery packs. Normal operation does not require extra batteries, which again becomes a burden on the car, reducing its operating capacity; the cost of using the battery also increases.

[0023] The input torque of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com