Vertical folding mechanism of folding machine

A stacking machine and vertical folding technology, which is applied in the direction of folding thin materials, sending objects, thin material processing, etc., can solve the problems of inaccurate position, deviation, and inability to move synchronously with the belt on the drawing creases, and achieve convenient installation , Easy and quick operation, accurate position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

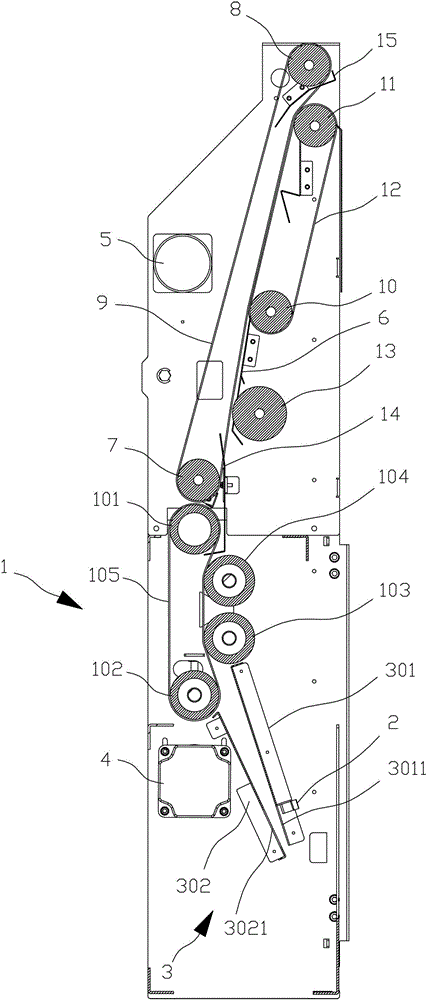

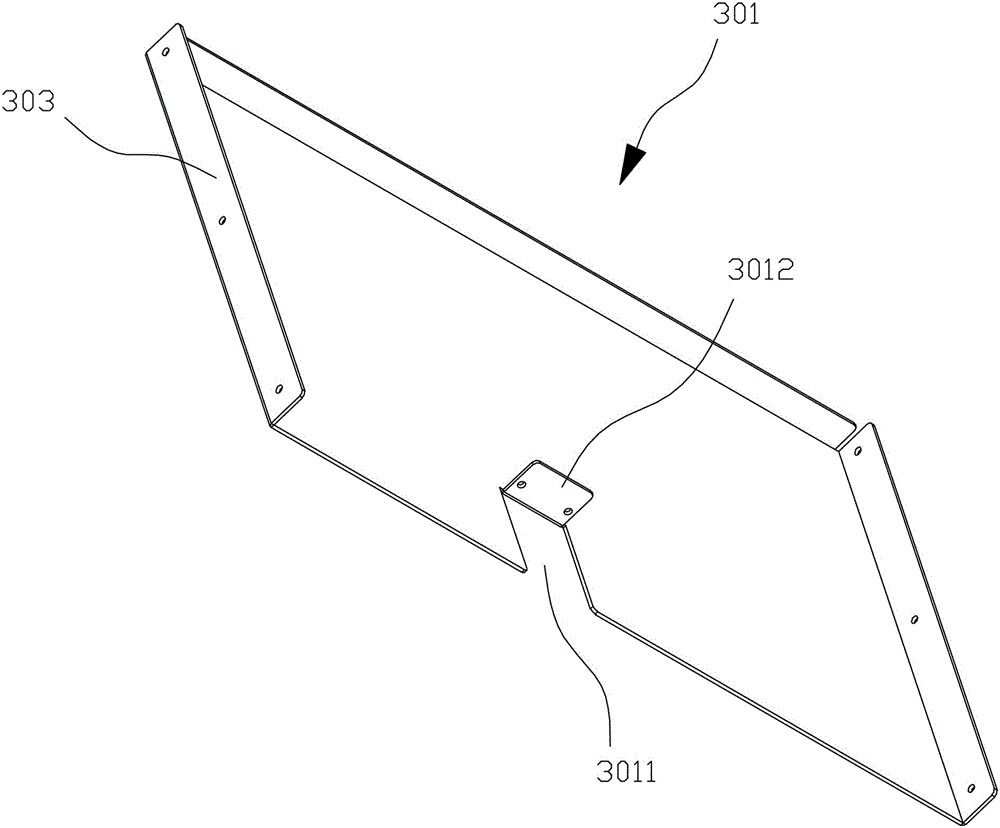

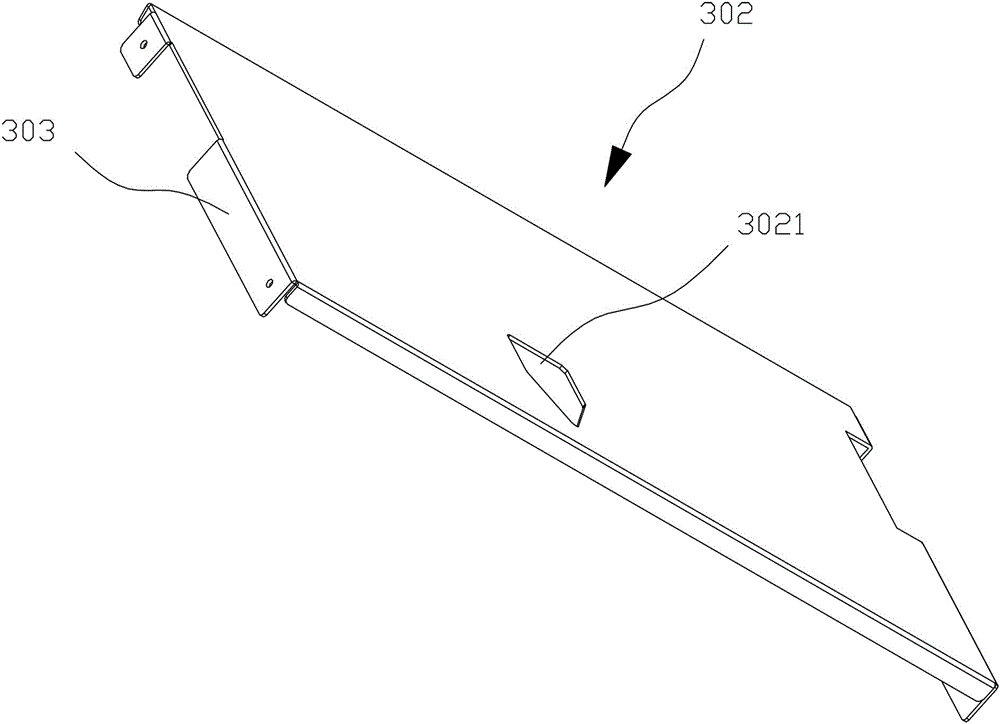

[0022] The vertical folding mechanism of the folding machine of the present invention includes a folding part 1 , a sensor 2 and a guiding part 3 .

[0023] Described origami part 1 comprises driving roller 101, driven roller 102, first auxiliary roller 103, second auxiliary roller 104 and belt 105, and belt 105 is closely matched with the periphery of driving roller 101 and driven roller 102, and first auxiliary roller 103 and the second secondary roller 104 are all in close contact with the outer surface of one side of the belt 105, the first secondary roller 103 is close to the passive roller 102, and the second secondary roller 104 is close to the driving roller 101, that is, as figure 1 As shown in , the passive roller 102 is positioned directly below the driving roller 101, the first secondary roller 103 is positioned directly b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap