A composite photonic film for multiple development and preparation method thereof

A multi-development, photonic technology, applied in chemical instruments and methods, optics, optical components, etc., can solve unseen problems and achieve the effect of good diffuse reflection performance, optimized hardness and flexibility, and high front light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

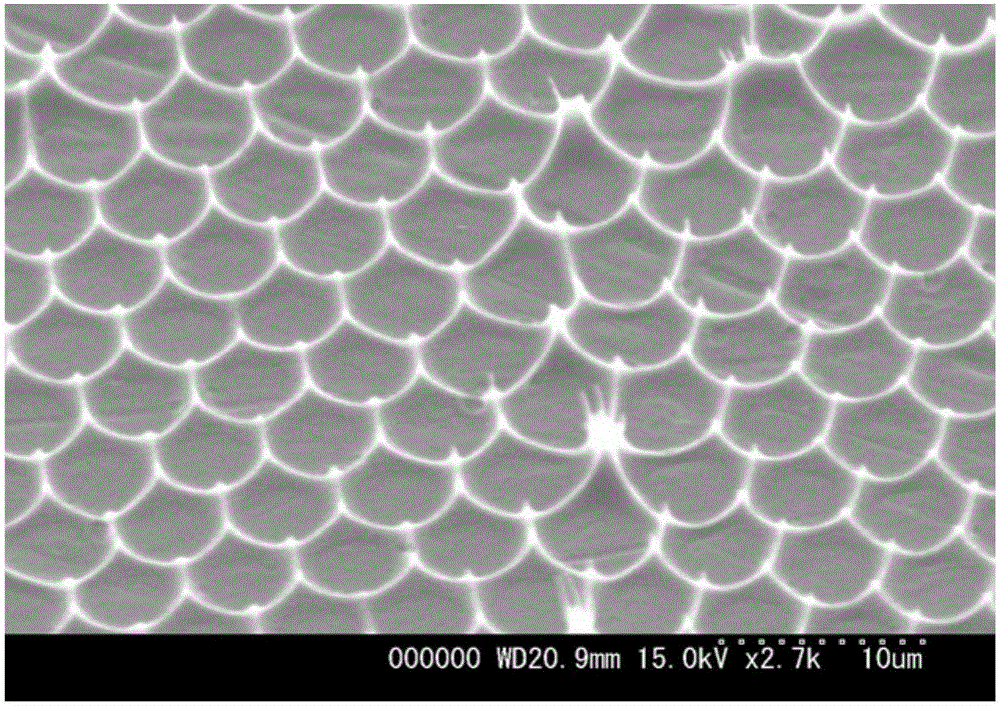

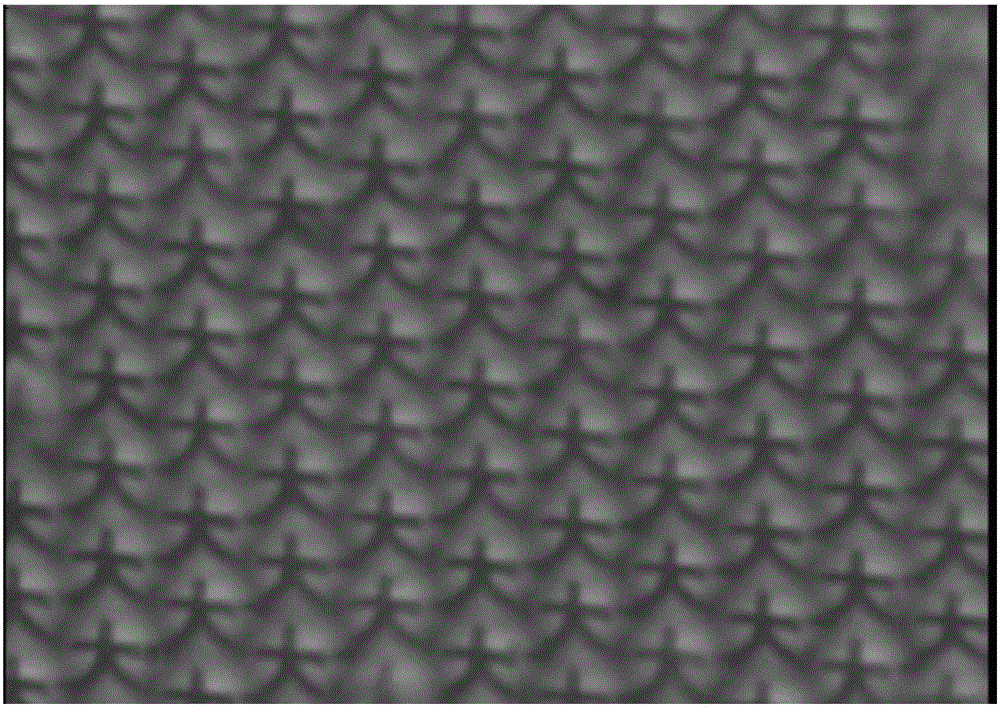

[0026] The chloroform solution of the PMMA of configuration 1g / L and PB mixture, PMMA and PB are configured according to the mass ratio 1:1 ratio, add the amphoteric copolymer polydodecyl acrylamide group that mass ratio is PMMA mass 1 / 2 in the solution- 6-acrylamidocaproic acid or copolymer polymethacrylmethacryloyloxyethyl-N,N-dimethyl-N-propanesulfonate amine salt-block-acrylamide until dissolved. Take the above solution at room temperature and place it in a petri dish with a diameter of 9cm. Methacryloxyethyl-N,N-dimethyl-N-propanesulfonic acid amine salt-block-acrylamide is 0.25g / L. The humid air flow with a relative humidity of 50% is blown to the surface of the solution at a speed of 4L / min, and soon an opaque film layer is formed on the surface of the polymer solution. After ten minutes, the solvent evaporates completely, and the film layer remains in the culture medium. The bottom of the dish; the surface of the ordered porous film is irradiated with ultraviolet rays...

Embodiment 2

[0029] The chloroform solution of the PMMA of configuration 1g / L and PB mixture, PMMA and PB are configured according to mass ratio 1:3 ratio, add the amphoteric copolymer polydodecyl acrylamide group that mass ratio is PMMA quality 1 / 2 in solution- 6-acrylamidocaproic acid or copolymer polymethacrylmethacryloyloxyethyl-N,N-dimethyl-N-propanesulfonate amine salt-block-acrylamide until dissolved. Take the above solution at room temperature and place it in a petri dish with a diameter of 9cm. Methacryloyloxyethyl-N,N-dimethyl-N-propanesulfonic acid amine salt-block-acrylamide is 0.125g / L. The humid air flow with a relative humidity of 50% is blown to the surface of the solution at a speed of 4L / min, and soon an opaque film layer is formed on the surface of the polymer solution. After ten minutes, the solvent evaporates completely, and the film layer remains in the culture medium. dish bottom. The surface of the ordered porous membrane is irradiated with ultraviolet rays, and t...

Embodiment 3

[0032] The chloroform solution of the PMMA of configuration 5g / L and PB mixture, PMMA and PB are configured according to mass ratio 1:1 ratio, add the amphoteric copolymer polydodecyl acrylamide group that mass ratio is PMMA quality 1 / 2 in solution- 6-acrylamidocaproic acid or copolymer polymethacrylmethacryloyloxyethyl-N,N-dimethyl-N-propanesulfonate amine salt-block-acrylamide until dissolved. Take the above solution at room temperature and place it in a petri dish with a diameter of 9cm. Methacryloxyethyl-N,N-dimethyl-N-propanesulfonic acid amine salt-block-acrylamide is 1.25g / L. The humid air flow with a relative humidity of 50% is blown to the surface of the solution at a speed of 4L / min, and soon an opaque film layer is formed on the surface of the polymer solution. After ten minutes, the solvent evaporates completely, and the film layer remains in the culture medium. dish bottom. The surface of the ordered porous membrane is irradiated with ultraviolet rays, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com