Hammering closing repair method for fatigue crack of steel bridge

A fatigue crack and repair method technology, applied in bridge maintenance, bridge, bridge reinforcement, etc., can solve problems such as unsuitable for steel bridges, complex structures, etc., achieve the effect of changing the stress intensity factor, improving the stress situation, and increasing the fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

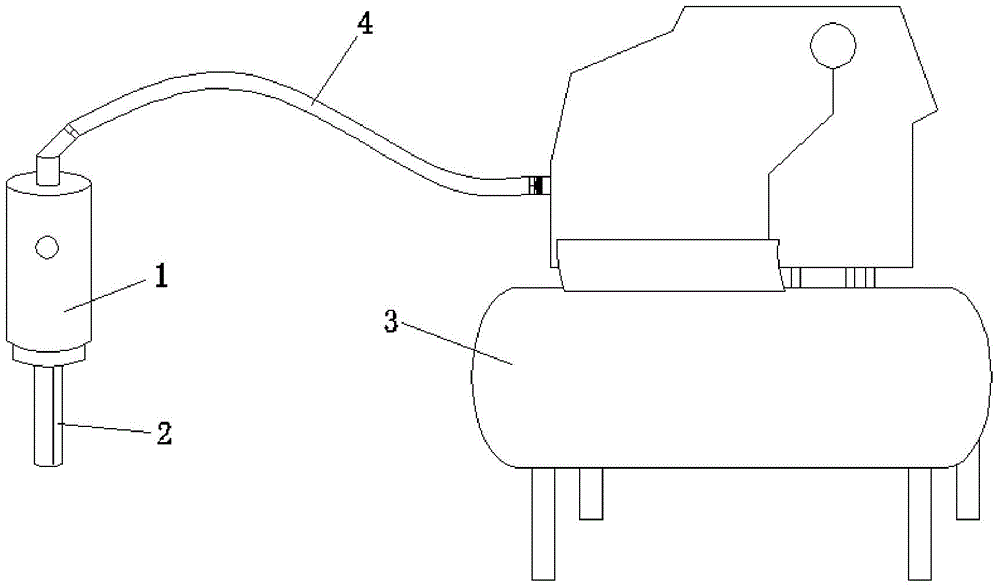

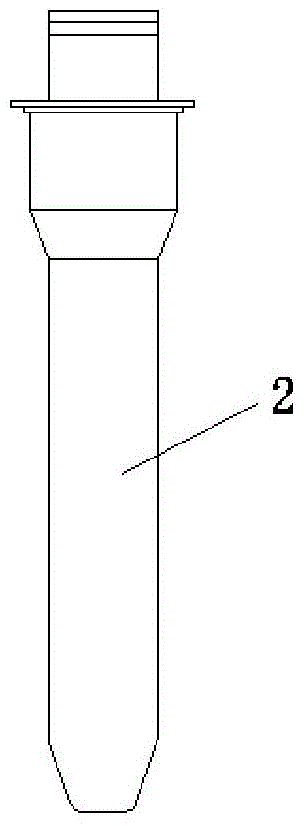

[0031] like figure 1 and figure 2 As shown in Fig. 1, the equipment for repairing steel bridge fatigue cracks by hammering closed cracks mainly includes pneumatic hammer 1, striker 2, and air compressor 3. The pneumatic hammer 1 is connected to the air compressor 3 through the air conduit 4 , and the striker 2 is inserted into the pneumatic hammer 1 to form a whole with the pneumatic hammer 1 . The air compressor 3 adopts a small portable air compressor to deliver the compressed air to the pneumatic hammer 1 to drive the striker 2 to perform hammering movement up and down, and to apply a hammering load to the surface of the steel plate 5 with fatigue cracks 7 . The specific working parameters of the air compressor 3 and the pneumatic hammer 1 vary according to the strength of the steel plate 5 to be processed.

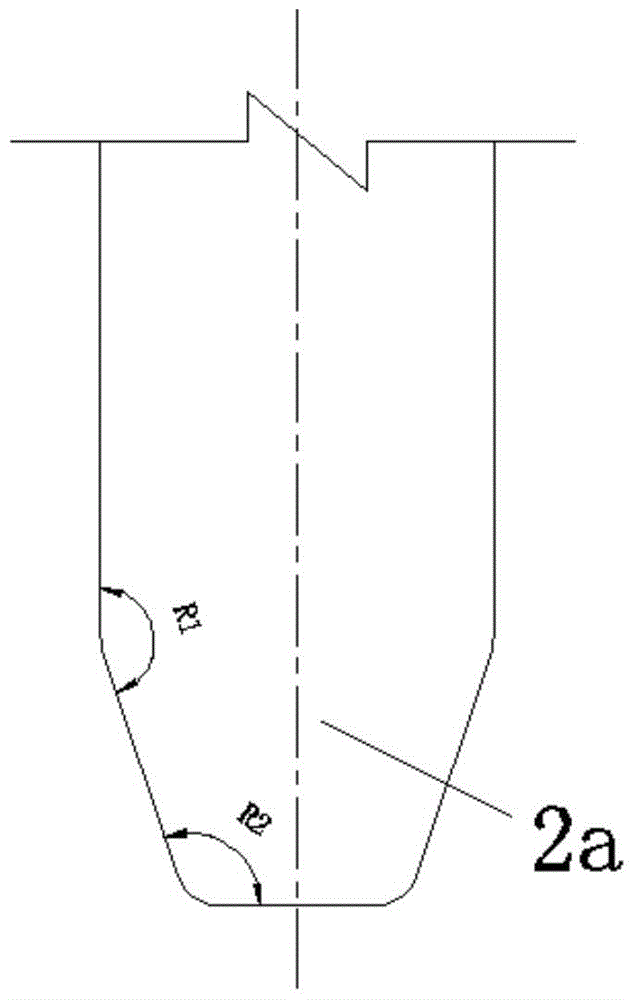

[0032] As shown in Figure 3, the striker head 2a is in the shape of an inverted trapezoid with an area of 4mm×5mm, which can increase the hammering strength 13a u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap