Ventilation method for high-temperature mine mining area

A ventilation method and mining area technology, applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve problems such as unfavorable cooling, and achieve the effect of good ventilation and cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

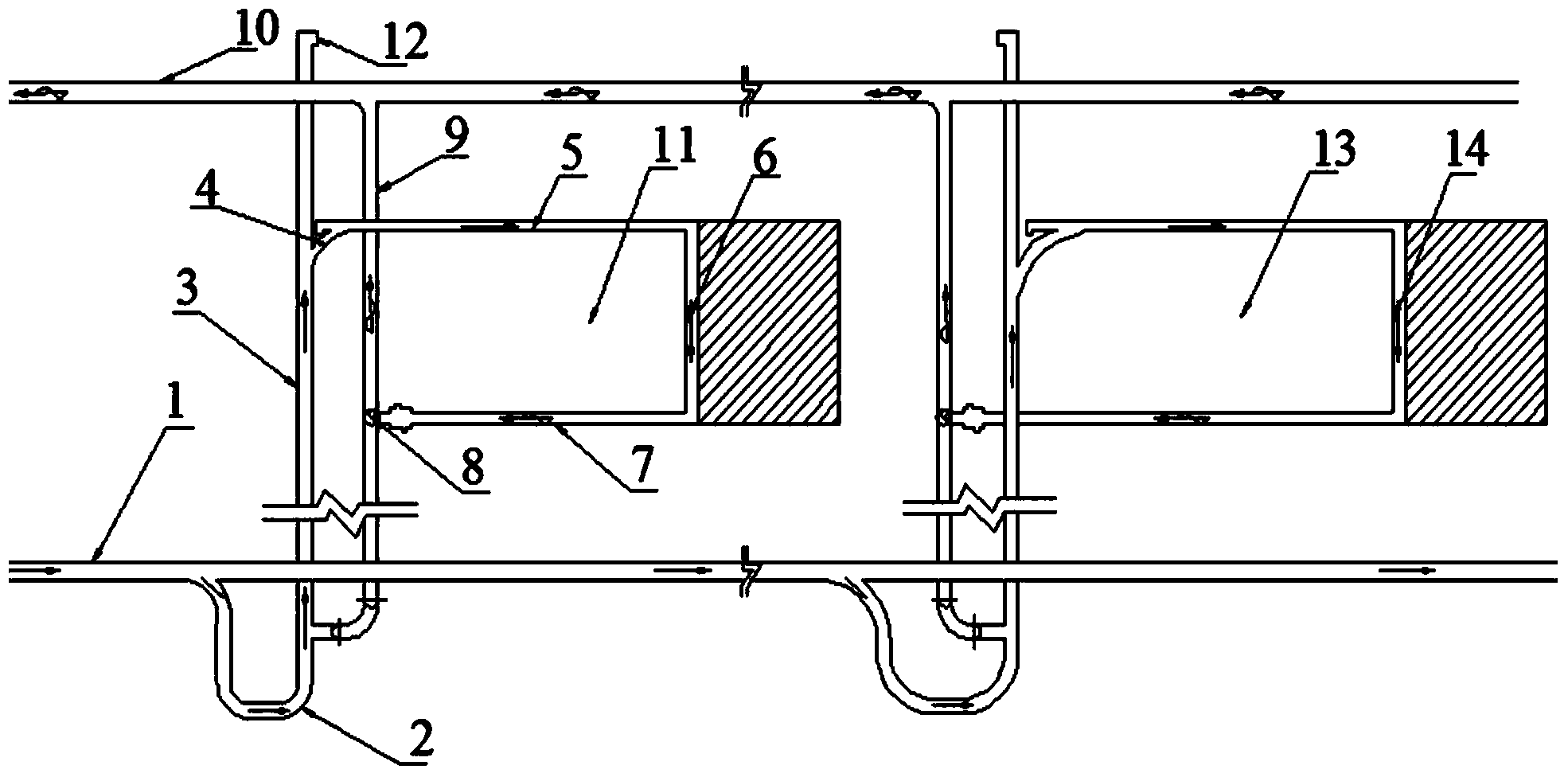

[0030] like figure 1 As shown in the figure, the front mining area 11 and the rear mining area 13 of the adjacent mining areas are arranged in the single-wing production mode; Go up the mountain 3, pass through the central parking lot 4 of the former mining area, enter the track (air intake) level lane 5 of the coal mining working face in the former mining area, enter the coal mining working face belt conveyor (return air) level lane 7 of the former mining area through the working face 6, and enter The transporter (return air) in the front mining area goes up the mountain 9, merges into the centralized return air alley 10, and finally returns to the ground through the general return air shaft of the mine; the coal mining face 6 in the front mining area and the coal mining face 14 in the rear mining area are Downward ventilation, the direction of wind flow is consistent with the direction of coal flow.

[0031] The high-temperature mine mining area ventilation method of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com