Ignition device of small gasoline engine generator

A gasoline generator and ignition device technology, applied in engine ignition, spark ignition controller, engine components, etc., can solve the problems of affecting the direction of cooling air, poor ventilation and cooling effect, large space, etc., to achieve good ventilation and cooling effect, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

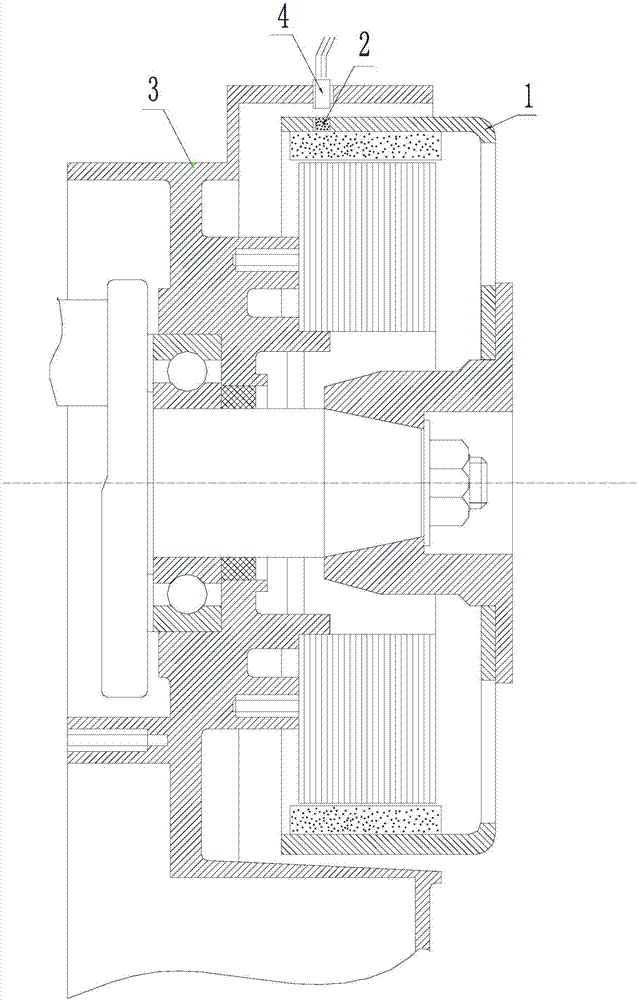

[0013] according to figure 1 The ignition device for a small gasoline generator includes a rotor 1 and a gasoline case body 3. The rotor 1 is installed in the gasoline case body 3, and is characterized in that: the outer circumference of the rotor 1 is equipped with a small magnet 2. A small hole is provided on the outer side of the circumference of the rotor 1, and the small magnetic steel 2 is embedded in the small hole. The diameter of the small hole is determined according to the diameter of the small magnetic steel. The inner side of the gasoline case body 3 corresponds to the small magnetic steel 2 There is a Hall element sensor 4, and the small magnetic steel 2 and the Hall element sensor 4 cooperate with each other to generate an induction signal for controlling the ignition system of the gasoline engine for ignition.

[0014] The working principle of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com