Multi-layer impact non-ferrous metal fine grinding machine

A non-ferrous metal and grinding machine technology, which is applied in the field of multi-layer impact non-ferrous metal fine grinding machine, which can solve the problems of complex production, affecting efficiency, and failure of grinding bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

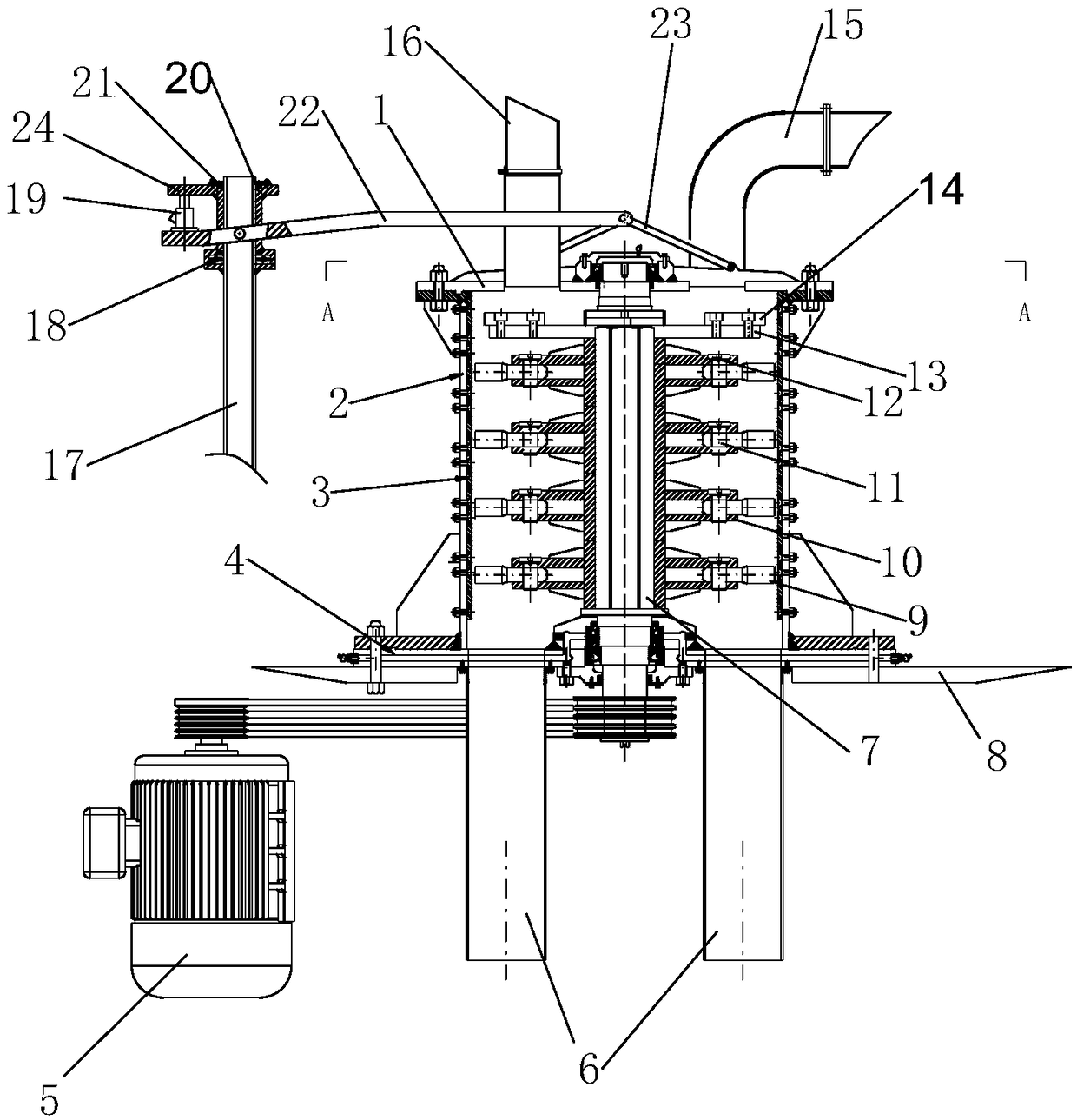

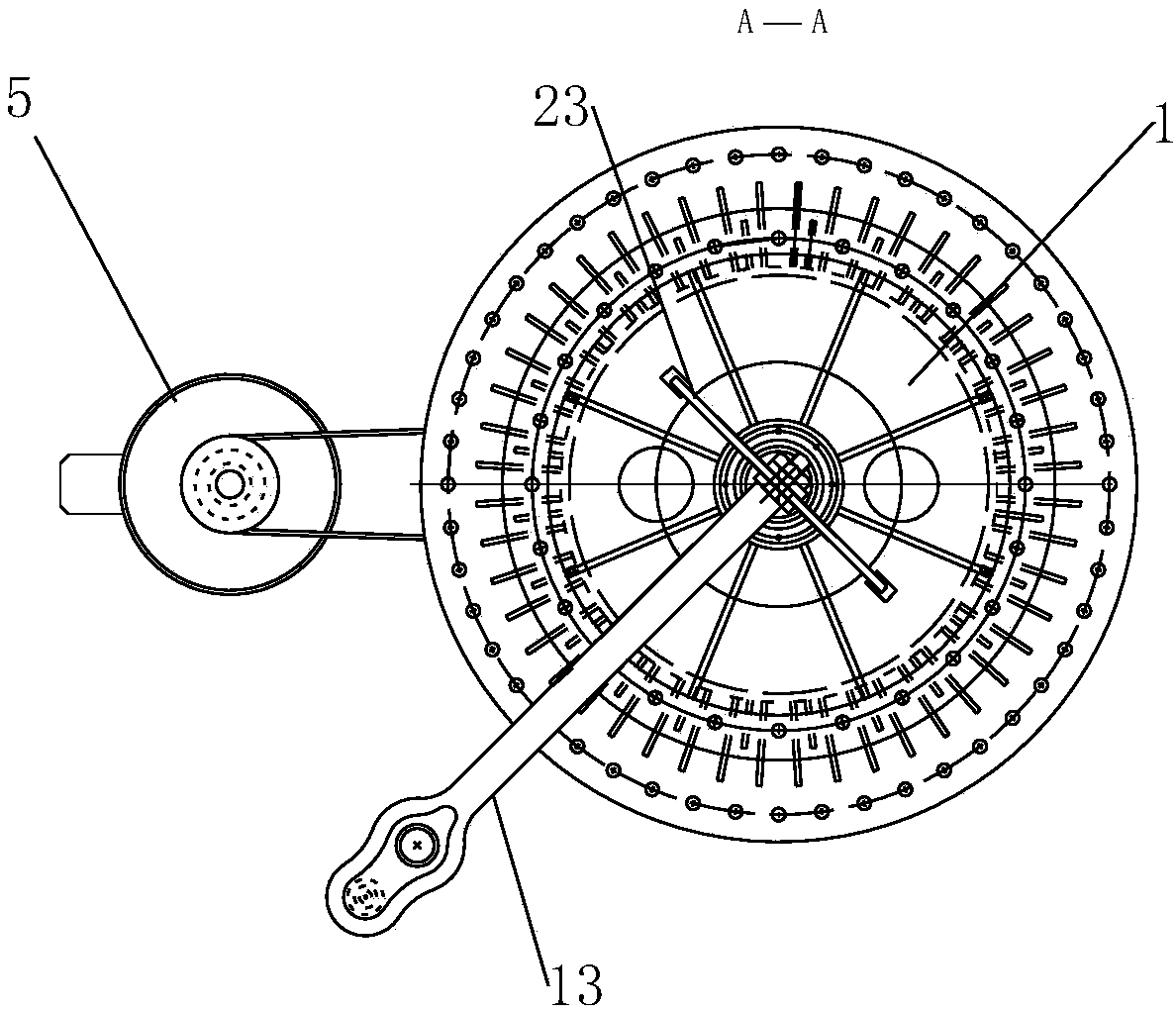

[0021] The present invention as Figure 1-5 As shown, it includes a cylindrical grinding machine body 2, the top of the grinding machine body is provided with an upper bearing seat cover 1, and the bottom is provided with a lower bearing seat 4, and the upper bearing seat cover is provided with a feed port 15, and the lower bearing seat The seat is provided with a discharge port 6;

[0022] The center of the grinding machine body is provided with a rotating rotating shaft 7, on which several hammerhead seats 10 are arranged, and several hammerheads 9 are connected on the hammerhead seat, and the inner wall of the grinding machine body is provided with a wear-resistant liner 3;

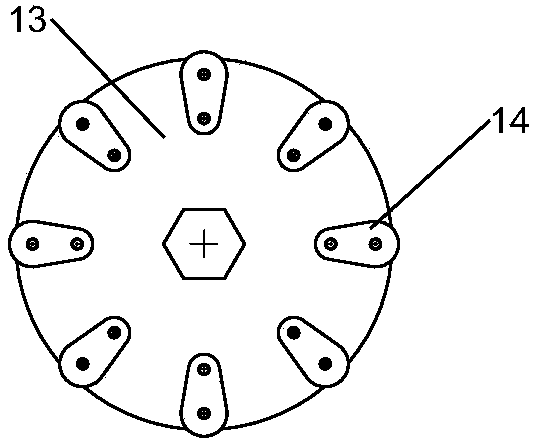

[0023] The rotating shaft is provided with a distributing disc 13, which is located above the uppermost hammer seat on the rotating shaft, and a plurality of grinding bodies 14 are evenly distributed on the circumference of the top surface of the distributing disc.

[0024] The hammer head seat is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com