A photon energy boiler energy saving and environmental protection device

A technology of photon energy, energy saving and environmental protection, applied in the direction of combustion method, gas fuel burner, combustion type, etc., can solve the problems of low combustion rate of boilers, waste gas emission pollution, low thermal efficiency, etc., to improve combustion efficiency, promote fission, improve Effects of Heat Transfer and Thermal Injection Velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

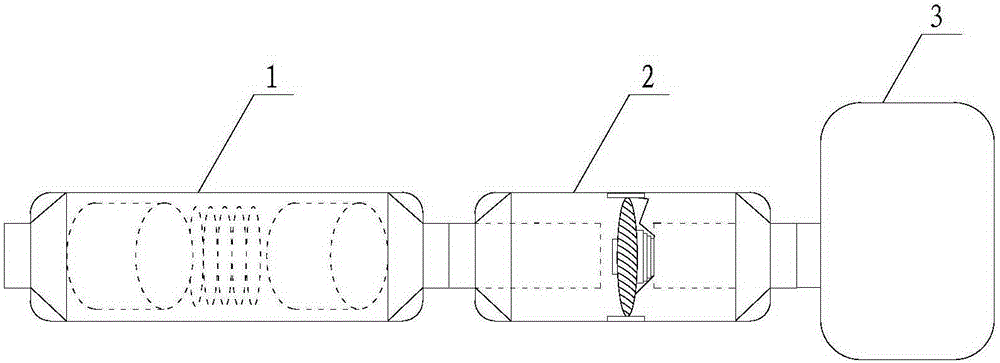

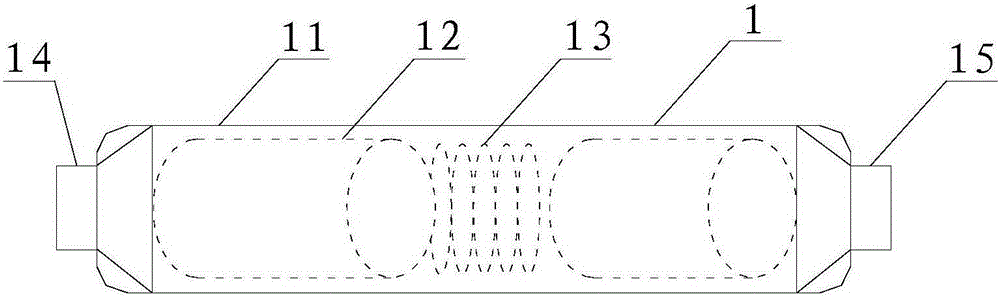

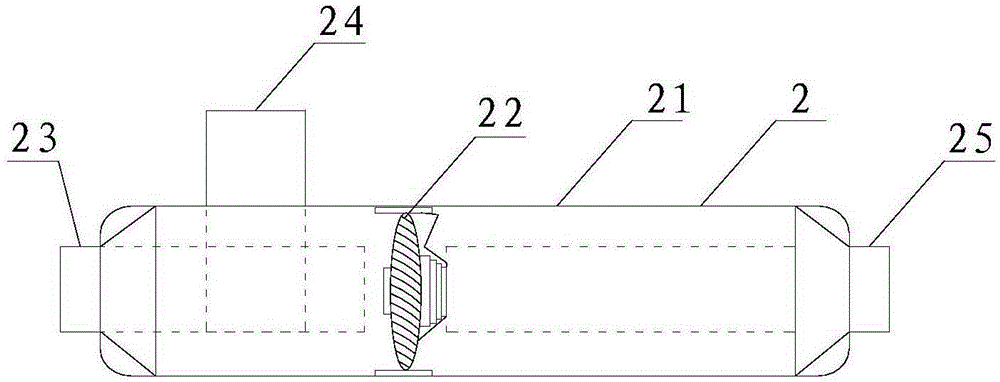

[0019] see Figure 1 to Figure 5 ,in figure 1 The structure of an energy-saving and environmental protection device for a photon energy boiler proposed by the present invention; figure 2 Yes figure 1 The enlarged view of the structure of the fuel gas pretreatment device described in; image 3 Yes figure 1 An enlarged view of the structure of the premixing device described in .

[0020] like figure 1 , figure 2 and image 3 As shown, a photon energy boiler energy saving and environmental protection device is characterized in that it includes a fuel gas pretreatment device 1, a premixing device 2 and a combustion chamber 3, and the fuel gas pretreatment device 1 includes a casing 11, a ceramic chip 12 and a spring 13. One end of the casing 11 is provided with a fuel gas inlet 14, the other end of the casing 11 is a fuel gas outlet 15, the ceramic chips 12 are arranged inside the casing 11, and the ceramic chips 12 are arranged between the ceramic chips 12. Spring 13; t...

Embodiment 2

[0038] An embodiment of a ceramic chip provided by the present invention is: the components and proportions of the ceramic chip are: 15% of zirconium-cerium oxide solid solution, 4% of manganese oxide, 3% of cobalt oxide, 4% of titanium oxide, 6% of chromium oxide %, lanthanum oxide 4%, iron oxide 2%, yttrium oxide 3%, molybdenum sulfide 5%, silicon carbide (or silicon oxide or silicon nitride or silicon acetate) 25%, tourmaline 25%, adhesive 4%.

[0039] The above materials (except lanthanide rare earth elements and zirconium-cerium oxide solid solution) are ball-milled to 1000 mesh and mixed, calcined at a temperature of 750 degrees for 10 hours, and then ball-milled to 2000 mesh again. It is prepared by the method, and then the adhesive is added for stamping and molding, and then it is calcined at 1232 degrees.

Embodiment 3

[0041] The second embodiment of a ceramic chip provided by the present invention is: the components and proportions of the ceramic chip are: 12% of zirconium cerium oxide solid solution, 5% of manganese oxide, 3% of cobalt oxide, 5% of titanium oxide, Chromium 6%, lanthanum oxide 5%, iron oxide 5%, yttrium oxide 2%, molybdenum sulfide 7%, silicon carbide (or silicon oxide or silicon nitride or silicon acetate) 20%, tourmaline 30%, adhesive 5 %.

[0042] The above materials (except lanthanide rare earth elements and zirconium-cerium oxide solid solution) are ball-milled to 480 mesh and mixed, calcined at 900 degrees for 8.5 hours, and then ball-milled to 1800 mesh again. It is prepared by the method, and then the adhesive is added for stamping and molding, and then it is calcined at 1180 degrees.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap