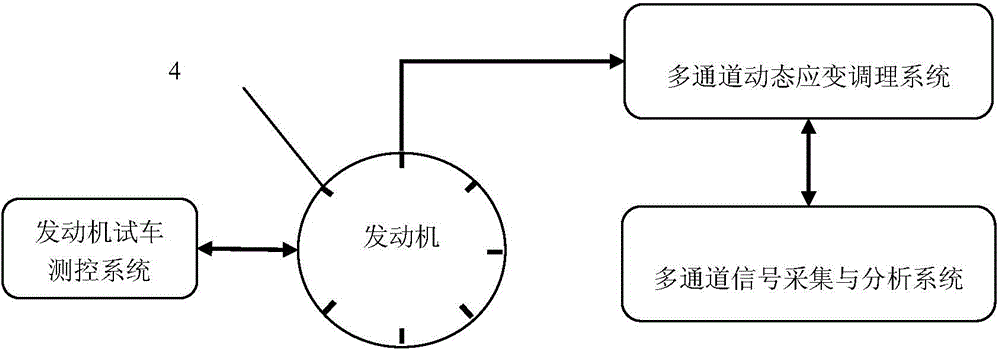

Dynamic stress testing method for stator vane under operating state of gas turbine engine

A technology of engine operation and gas turbine, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of difficult realization of dynamic test conditions, and achieve the effect of real test data, complete information, and real and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

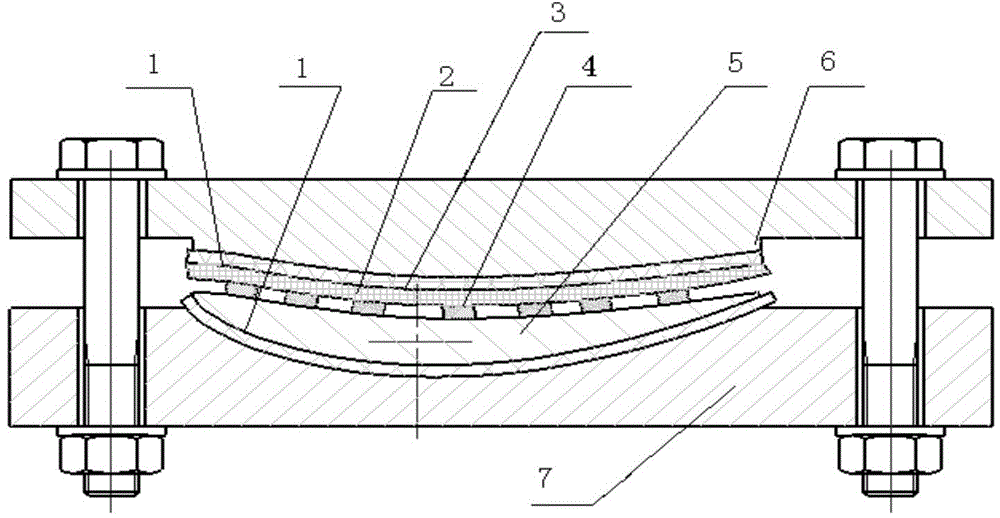

[0013] 1. Determine the sticking position of the strain gauge. Using modal tests and simulation calculations, the cloud map of the stress distribution of the guide vane or the stator blade under the actual constraint conditions is given, and the maximum stress area of the stress distribution on the cloud map is selected, combined with the actual location of the defect problems such as cracks or missing pieces of the blade to be analyzed , determine the pasting position of the strain gauge, and then paste the strain gauge on the leaf pot and the leaf back of the blade respectively according to the determined position;

[0014] 2. Sticking and curing of strain gauges. Since the blades are installed in the engine casing, the temperature inside the casing is generally close to 200°C during operation, and there are high pressure and flow velocity, so the strain gauges must be firmly pasted, otherwise if the engine falls off during the working process It will cause a safety hazar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com