Apparatus and methods for manufacturing components

A component and equipment technology, applied in the field of fiber composite components, can solve the problems of expensive and time-consuming processing cycles, achieve precise positioning, simplify side sealing, and improve repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

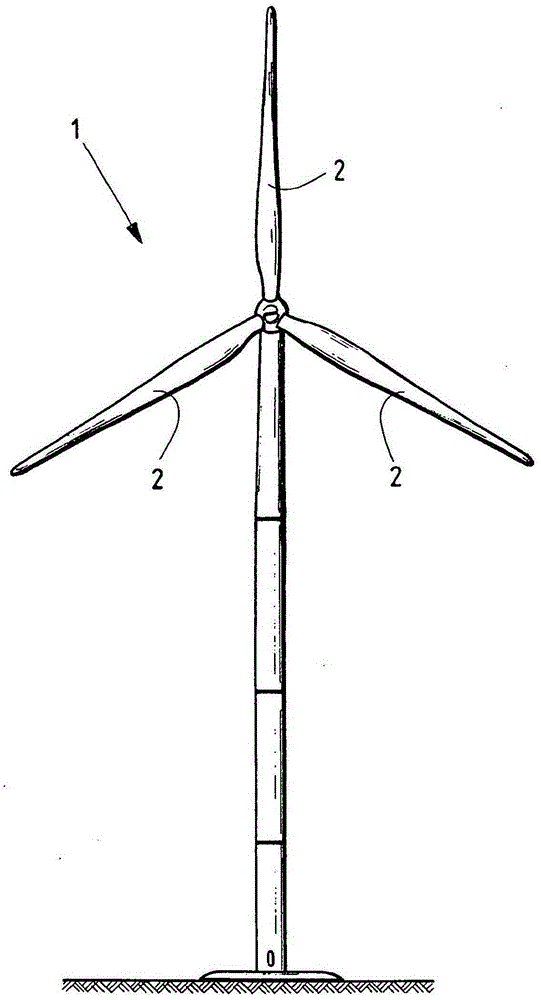

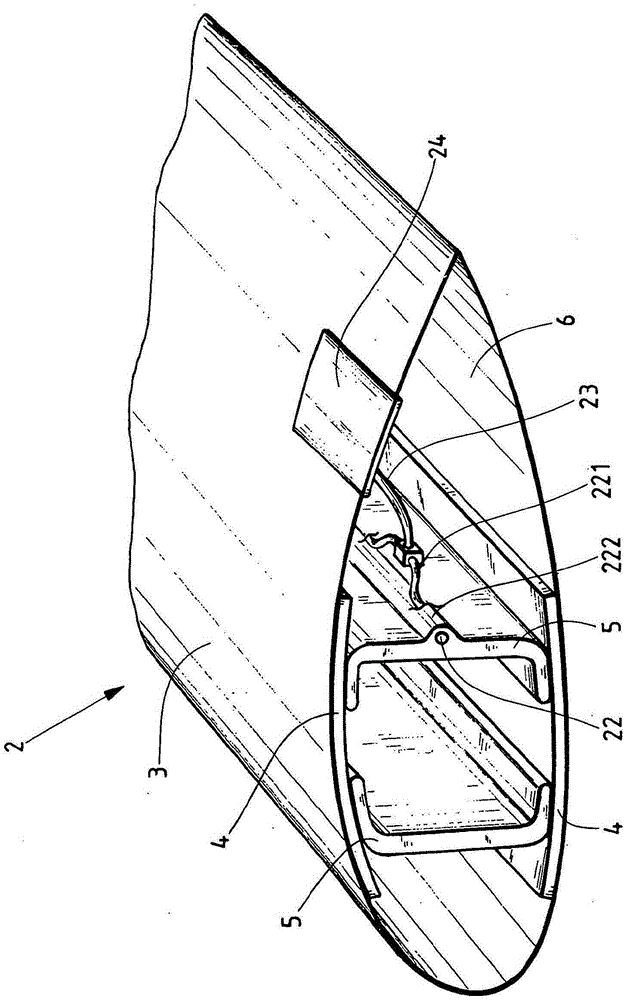

[0042] figure 1 A typical wind turbine 1 with three rotor blades 2 is shown, wherein the invention is not limited to a wind turbine of the type shown as an example. A perspective section view of one of the rotor blades 2 is at figure 2 shown in .

[0043] The supporting structure of the exemplary rotor blade 2 consists of two rotor blade strips 4 and two rotor blade webs 5 , which are bonded to form a spar box. This spar box supports the rotor blade shell 3 , which determines the aerodynamic properties of the rotor blade 2 . In the rear hollow space of the rotor blade 2, the rear box 6 is shown as part of the lightning protection device.

[0044] The lightning protection system comprises a receiver 24 which is incorporated in the rotor blade casing 3 so as not to impair the aerodynamic properties of the rotor blade 2 . The receiver 24 is grounded via a connecting cable 23 and a lightning cable 22 extending longitudinally in the rotor blade.

[0045] The lightning protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com