Drying adsorption tower convenient for maintenance

A dry adsorption, access door technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient replacement of activated carbon, inconvenient replacement, etc., to save maintenance time, convenient replacement, and maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

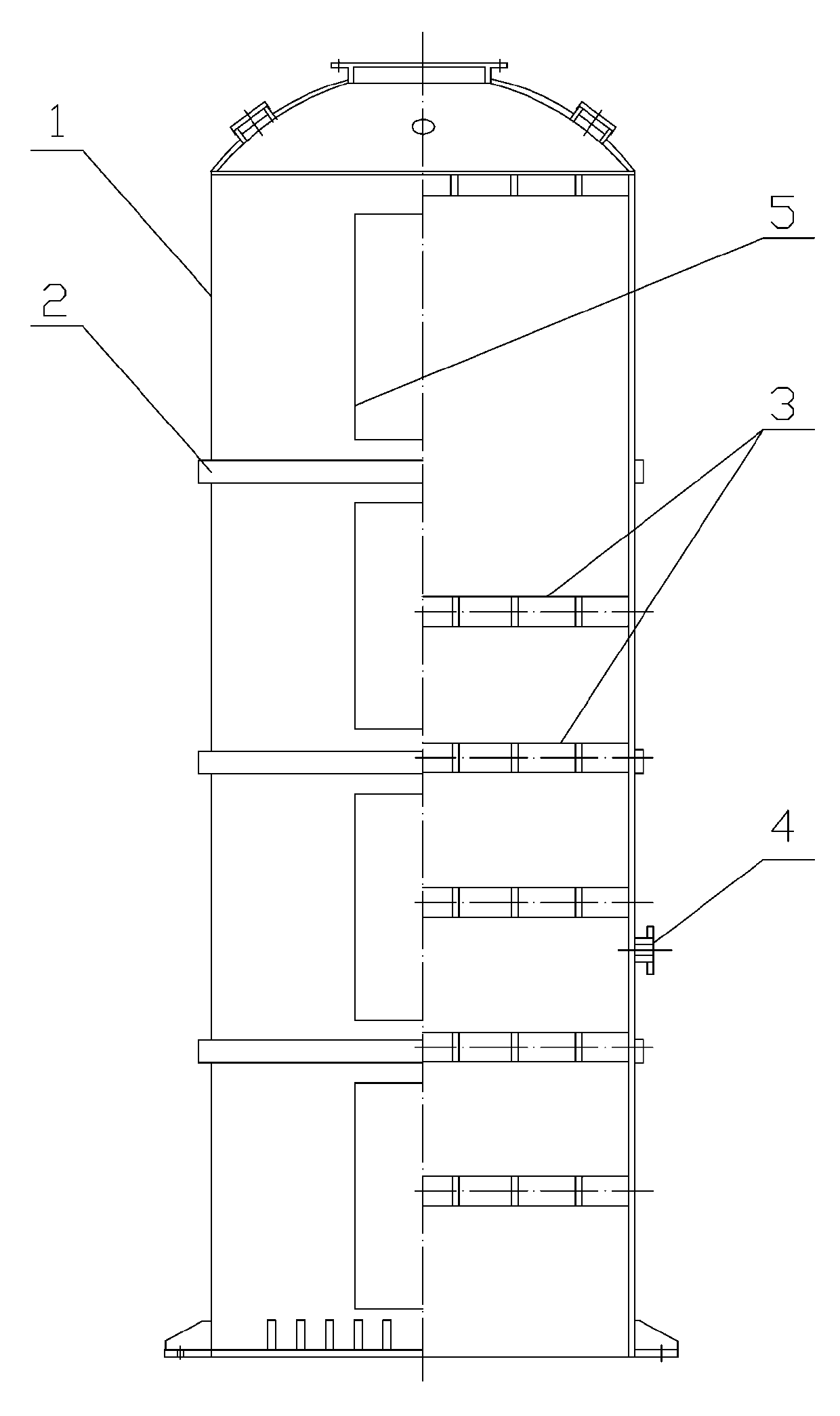

[0009] See figure 1 , The present invention has a cylinder 1, on which several layers of reinforcing hoops 2 are evenly distributed, several layers of evenly distributed shelves 3 are arranged in the cylinder 1, and on the cylinder 1 corresponding to each layer of shelves 2 are arranged above The activated carbon injection port 4 is characterized in that: an inspection door 5 is opened between every two layers of reinforcement hoop 2 on the cylinder body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com