Automatic protection type multipath motormeter pointer crimping device and method

An automatic protection type, automotive instrument technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of automotive instrument crushing and other problems, and achieve the effect of preventing the pointer from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

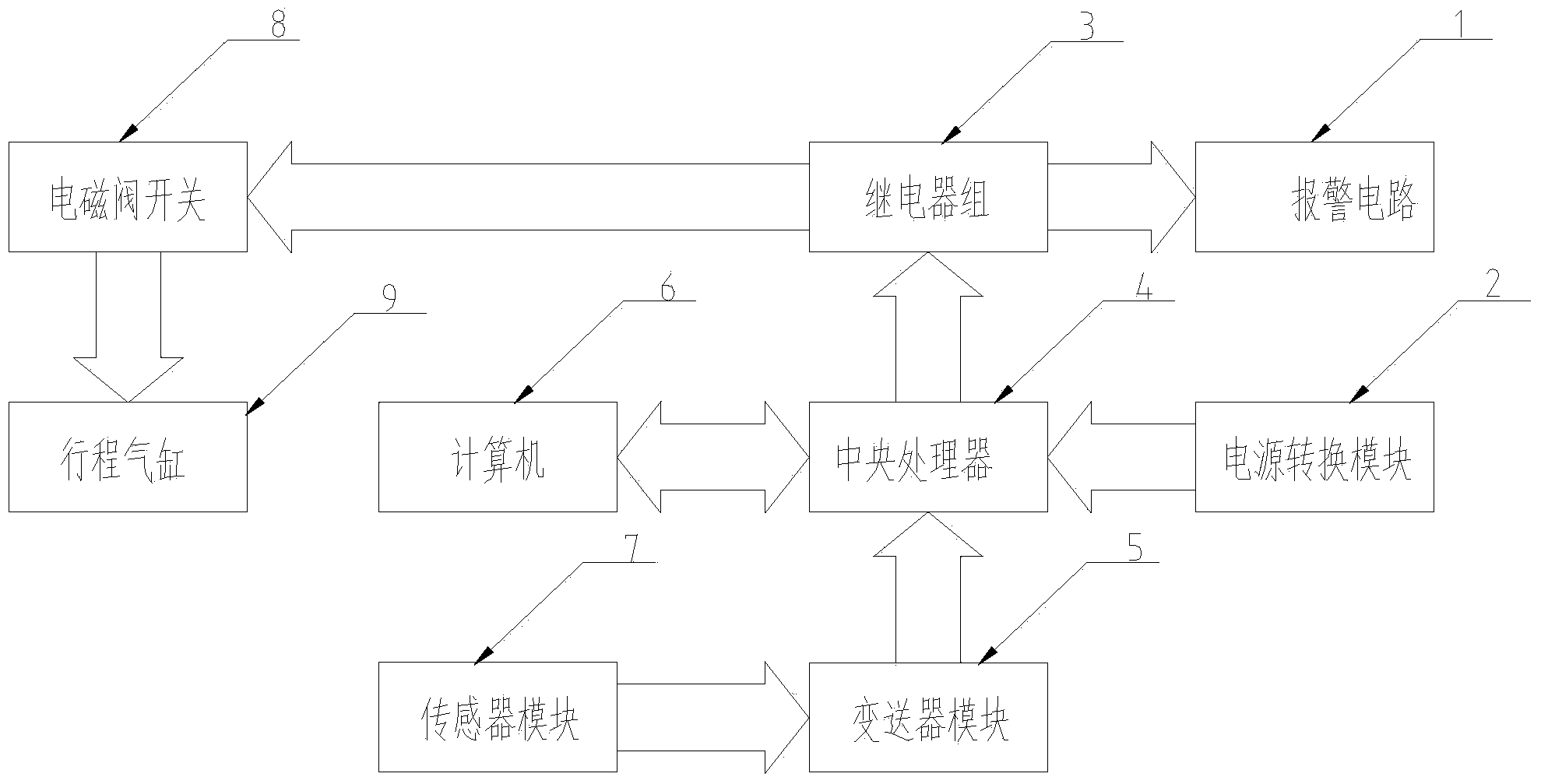

[0013] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the automatic protection type multi-channel automobile meter pointer crimping device described in this embodiment, the device includes an alarm circuit 1, a power conversion module 2, a relay group 3, a central processing unit 4, a transmitter module 5, a computer 6. Sensor module 7, solenoid valve switch 8 and stroke cylinder 9;

[0014] The alarm control signal input end of the alarm circuit 1 is connected to a switch signal output end of the relay group 3, the other switch signal output end of the relay group 3 is connected to the switch control signal input end of the solenoid valve switch 8, and the control signal input of the relay group 3 connected to the control signal output terminal of the central processing unit 4, the detection pressure signal output terminal of the sensor module 7 is connected to the analog signal input terminal of the transmitter module 5, and the digital signal...

specific Embodiment approach 2

[0015] Embodiment 2. This embodiment is a further description of the auto-protective multi-channel automotive instrument pointer crimping device described in Embodiment 1. The sensor module 7 is realized by a pressure detection circuit.

[0016] The device adopts electronically controlled mechanical pressing, which effectively monitors the pressure during the pressing process of the pointer and strictly limits the pressing position. The pressing process is convenient and easy to operate, and all hands are pressed at one time. It greatly improves the product qualification rate and saves manpower.

specific Embodiment approach 3

[0017] Specific Embodiment 3. This embodiment is a further description of the automatic protection type multi-channel automobile instrument pointer crimping device described in specific embodiment 1 or specific embodiment 2. The central processing unit 4 is realized by PLC technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com