A spherical roller bearing inner ring raceway grinder device and method thereof

A technology of bearing inner ring and spherical roller, applied in abrasive surface adjustment device, grinding machine, grinding machine parts and other directions, can solve the problems of low productivity and low grinding precision, and achieve cost saving, quality assurance, and improvement The effect of grinding accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

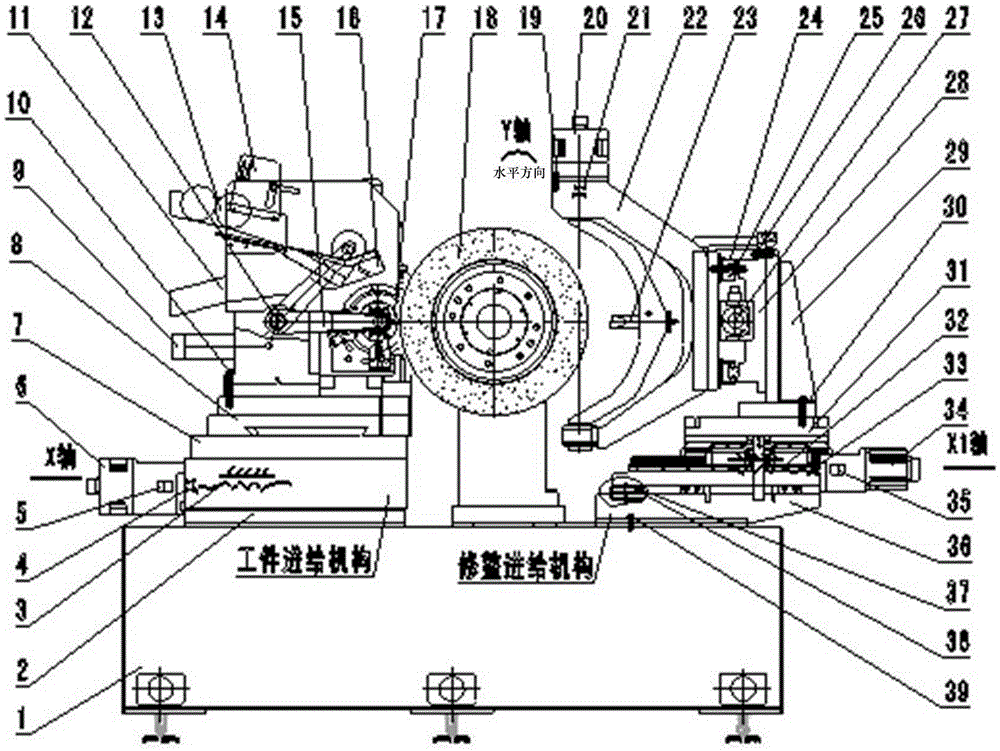

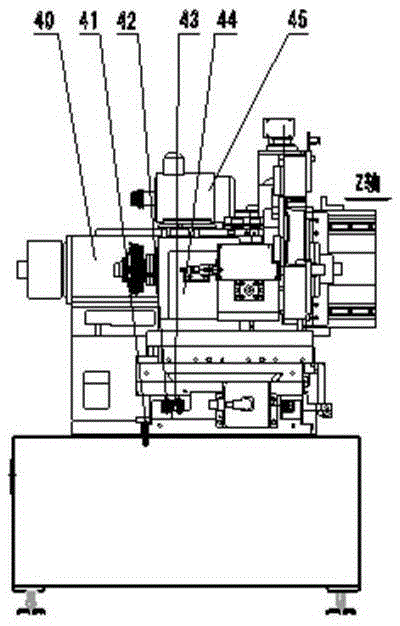

[0018] like figure 1 and figure 2 As shown, the spherical roller bearing inner ring raceway grinder device includes a bed 1, a workpiece feeding mechanism, a dressing compensation mechanism, a grinding wheel 18, and a grinding wheel shaft 40. The workpiece feeding mechanism includes a workpiece lower carriage 2, a first Ball screw 3, first screw bearing 4, first coupling 5, first servo motor 6, workpiece upper carriage 7, slide plate 8, oil cylinder 9, first hexagon socket head cap screw 10, feeding channel 11, upper and lower Material mechanism 12, feeding channel 13, material distribution rack 14, manipulator 15, material block 16, workpiece 17, eighth hexagon socket head screw 41, ninth hexagon socket head screw 42, first guide rail 43, workpiece shaft 44, motor 45 , the trimming compensation mechanism includes a second hexagon socket head cap screw 19, a fourth servo motor 20, a bearing 21, a bow bracket 22, a bow shape trimmer 23, a third guide rail 24, a third hexagon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com