System and method for controlling numerical-control grinding machine for forming convexity of inner ring of conical bearing

A technology for forming grinding machines and tapered bearings, which is applied to grinding automatic control devices, grinding machine parts, manufacturing tools, etc. It can solve problems affecting the shape of the machined surface, deformation of the grinding wheel shape, waste of lubricating oil, etc., and achieve quality assurance , to eliminate the effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

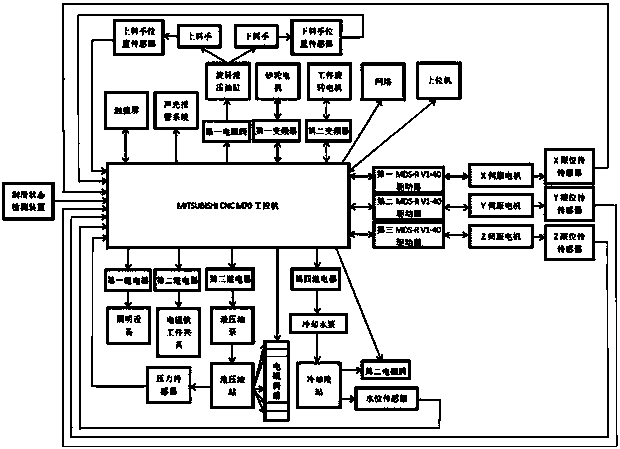

[0010] like figure 1 As shown, the control system of the CNC tapered bearing inner ring crown forming grinder includes the position sensor of the loading hand, the loading hand, the unloading hand, the position sensor of the unloading hand, the touch screen, the sound and light alarm system, the rotary hydraulic cylinder, and the first solenoid valve. , second solenoid valve, solenoid valve group, grinding wheel motor, first frequency converter, second frequency converter, workpiece rotating motor, upper computer, first MDS-R V1-40 driver, second MDS-R V1-40 driver, The third MDS-R V1-40 driver, X servo motor, X limit sensor, Y servo motor, Y limit sensor, Z servo motor, Z limit sensor, MITSUBISHI CNC M70 industrial computer, the first relay, Second relay, third relay, fourth relay, lighting equipment, electromagnet workpiece fixture, hydraulic oil pump, cooling water pump, pressure sensor, hydraulic oil station, second solenoid valve, first solenoid valve, solenoid valve grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com