High-frequency brake test platform control system

A braking experiment, high-frequency technology, applied in the testing of mechanical components, testing of machine/structural components, force/torque/work measuring instruments, etc., can solve the problem of small output force, poor heat resistance, small electromechanical coupling coefficient, etc. problems, to achieve the effect of eliminating waste and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

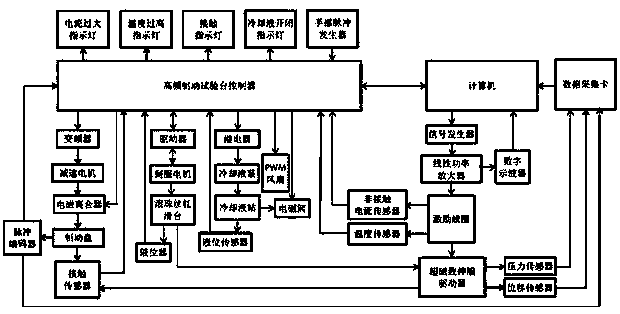

[0010] exist figure 1 The control system of the high-frequency braking test bench includes the high-frequency braking test bench controller, computer, data acquisition card, frequency converter, geared motor, electromagnetic clutch, brake disc, contact sensor, pulse coder, drive, servo Motor, ball screw slide, limiter, relay, coolant pump, coolant station, liquid level sensor, solenoid valve, PWM fan, non-contact current sensor, temperature sensor, signal generator, linear power amplifier, digital oscilloscope , excitation coil, giant magnetostrictive driver, pressure sensor, displacement sensor, overcurrent indicator light, overtemperature indicator light, contact indicator light, coolant on / off indicator light, hand pulse generator, high frequency braking experiment The controller is connected with the PWM fan, electromagnetic valve, electromagnetic clutch, manual pulse generator, coolant on and off indicator light, contact indicator light, over-temperature indicator light, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com