Automatic fixing device for container

A technology for fixing devices and containers, which is applied in the field of containers, can solve problems such as low efficiency, reduce danger, missing locks, etc., and achieve the effects of improving loading efficiency, improving transportation safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

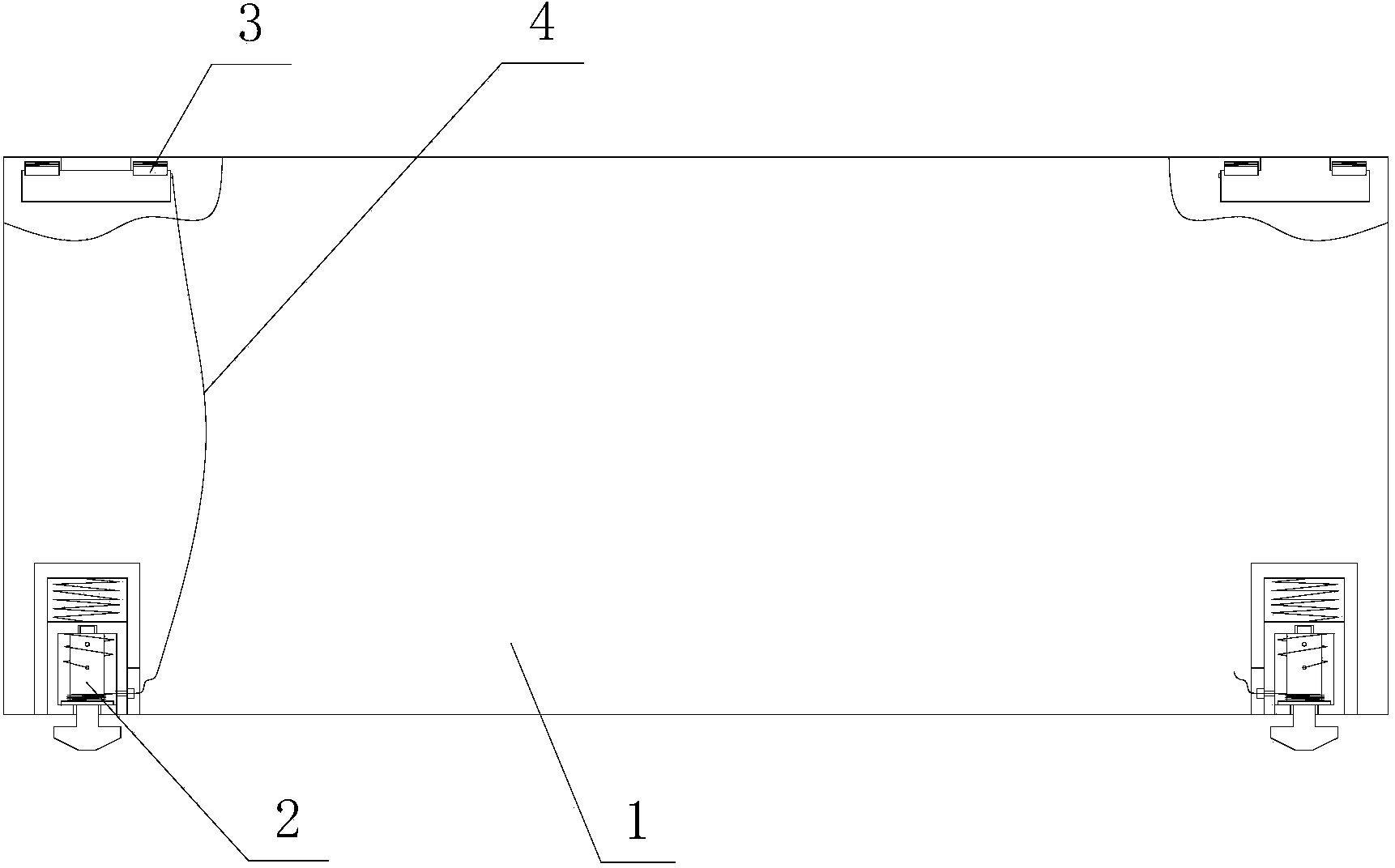

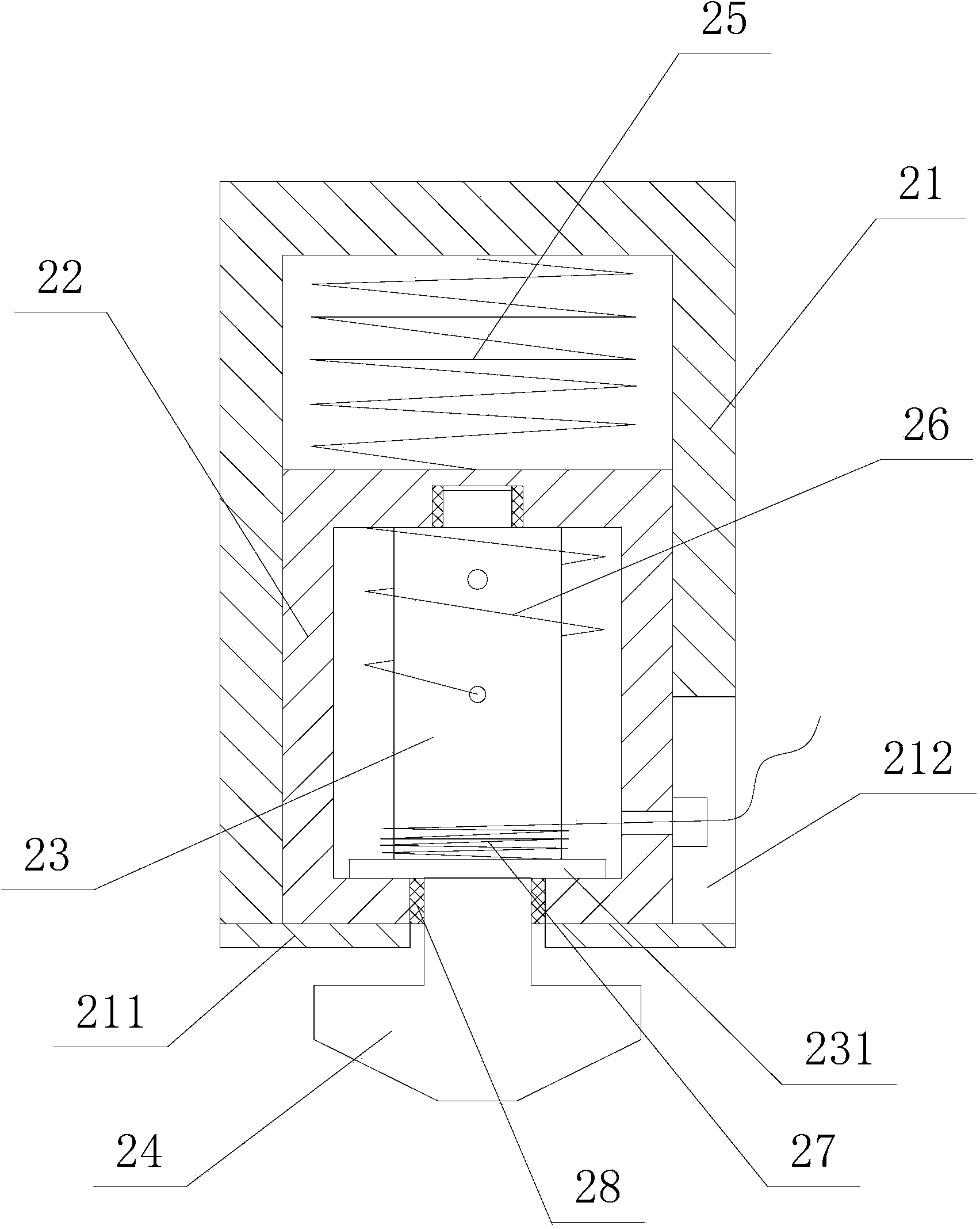

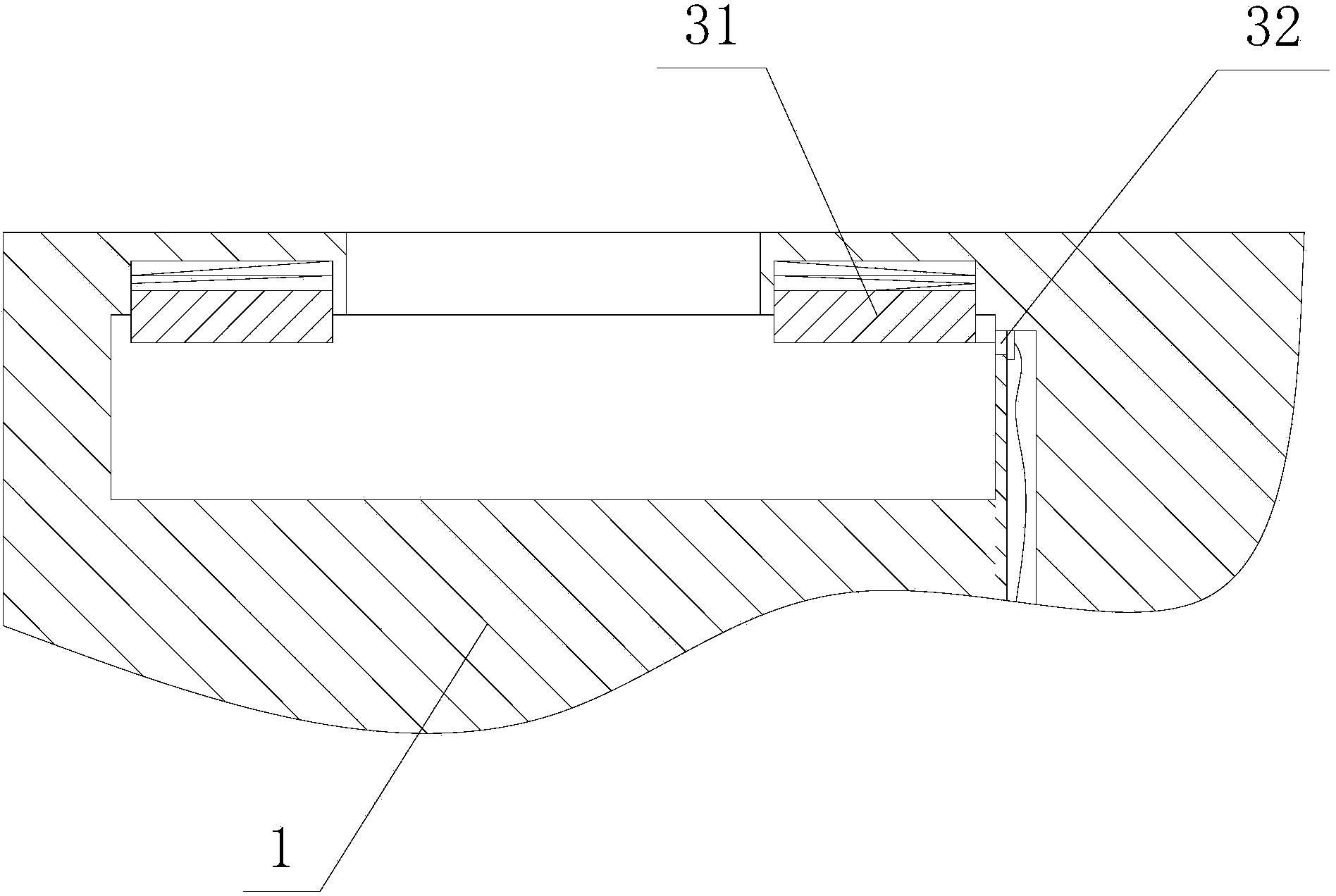

[0017] refer to Figure 1 ~ Figure 4 , the present invention provides an automatic container fixing device, comprising a container body 1, a locking device 2 is fixed on the bottom of the container body 1, and a fastening device 3 is fixed on the top of the container body 1, and the fastening device 3 communicates with the lock through a brake wire 4. The locking device 2 is connected, and the locking device is driven to act by pulling the brake line through the fastening device, so as to achieve the purpose of locking or unlocking. The locking device 2 includes an outer sleeve 21, an inner sleeve 22, a rotating shaft 23 and a lock head 24. The inner sleeve 22 is slidingly fitted in the outer sleeve 21, and a compression spring 25 is arranged on the upper surface of the inner sleeve 22, and the compression spring makes the inner sleeve move downward, and the rotating shaft 23 is installed in the inner sleeve rotatably. 22, and a torsion spring 26 is provided between the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com