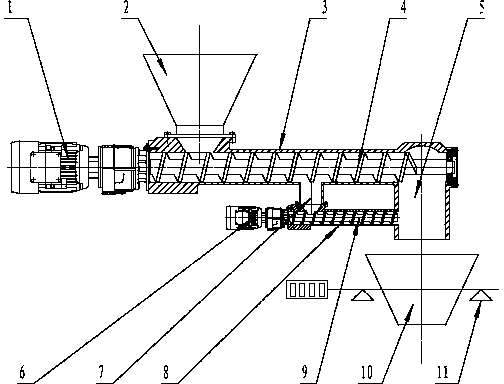

Double-step type metering screw conveyor

A metering screw and conveyor technology, which is applied in transportation and packaging, loading/unloading, packaging, etc., can solve the problems of formula raw material waste, feeding metering accuracy error, large feeding amount, etc., and achieve simple and convenient control procedures Precise feed and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the accompanying drawings, the raw material storage bucket (2) is fixed on the upper part of the large metering screw cylinder (3), the large metering screw drive motor (1) is fixed on the rear of the large metering screw cylinder (3), and the large metering screw motor (1 ) to drive the large metering screw feeding screw (4) to rotate, to transport the material from the raw material storage hopper (2) to the discharge port (5) and directly fall into the electronic scale hopper (10), when the load cell ( 11) When it is detected that the material in the electronic scale hopper (10) is close to the full scale of the set value, the large metering screw drive motor (1) stops working, and the small metering screw motor (6) fixed on the lower part of the large metering screw cylinder (3) ) to drive the small metering screw feeding screw (9) to rotate in the small metering screw barrel (8), conveying the material from the transition pipe (7) to the feeding port (5) and direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com