Preparation method and product of cemented sand and gravel with slurry and vibration

A technology of cemented sand and gravel and sand and gravel, applied in the field of improving the existing dam construction method, can solve the problems of high cost, slow construction progress, poor environmental protection performance, etc., and achieve the effects of low cost, improved construction efficiency, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] For ease of understanding, when we use natural sand and gravel from the source of material as the material to prepare a dam engineering protective layer with a design requirement of an impermeability level of W8 and a frost resistance level of F200, we will give an example of the implementation of the present invention. For example, the technical solution of the present invention will be explained in detail.

[0062] Among them, the natural sand and gravel in this embodiment, the sand ratio of the coarsest gradation, the finest gradation and the average gradation of the sand and gravel materials are 10.3%, 28% and 18%, respectively.

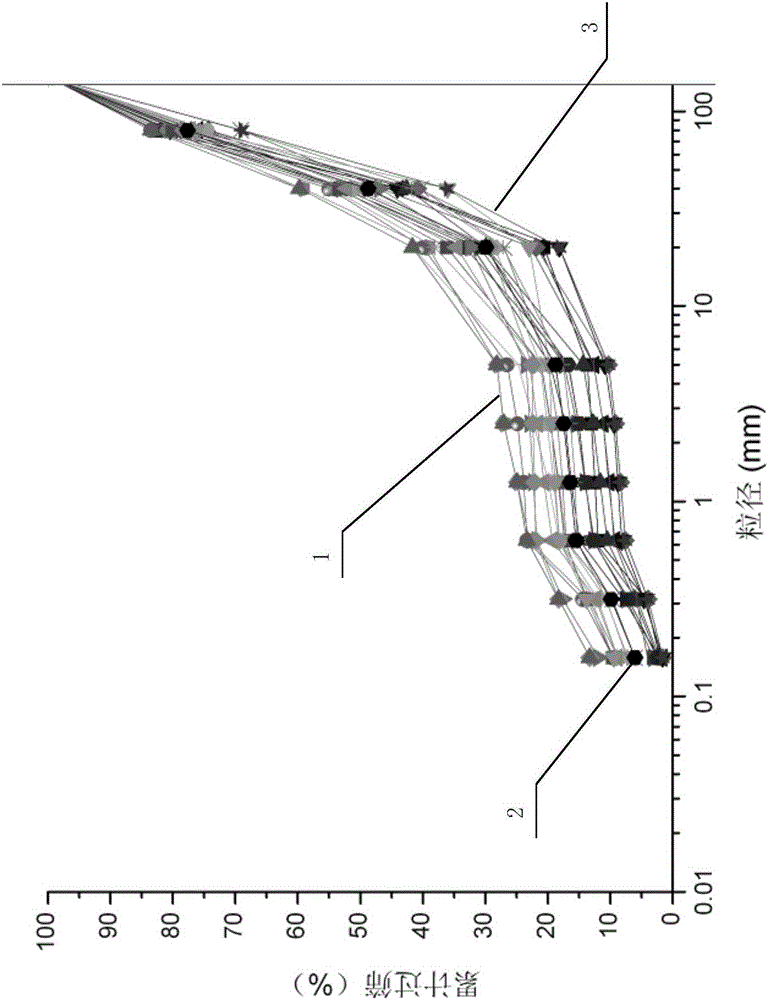

[0063] Remove particles with a particle size of 150mm or more, and draw the envelope curve of the natural sand and gravel gradation curve based on the finest, average and coarsest gradations of the natural sand and gravel samples collected (22 in this example) (See figure 1 ), the finest gradation 1, the average gradation 2, and the coarsest gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com