Leather brush-off finishing processing technology

A leather and color coating technology, which is applied in the field of leather color rubbing and finishing treatment, can solve the problems of poor treatment effect and inability to form multi-color effects, etc., and achieve the effect of long retention time and high aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The leather color rubbing and finishing treatment technology includes the following steps:

[0018] ①, the ratio of the treatment liquid

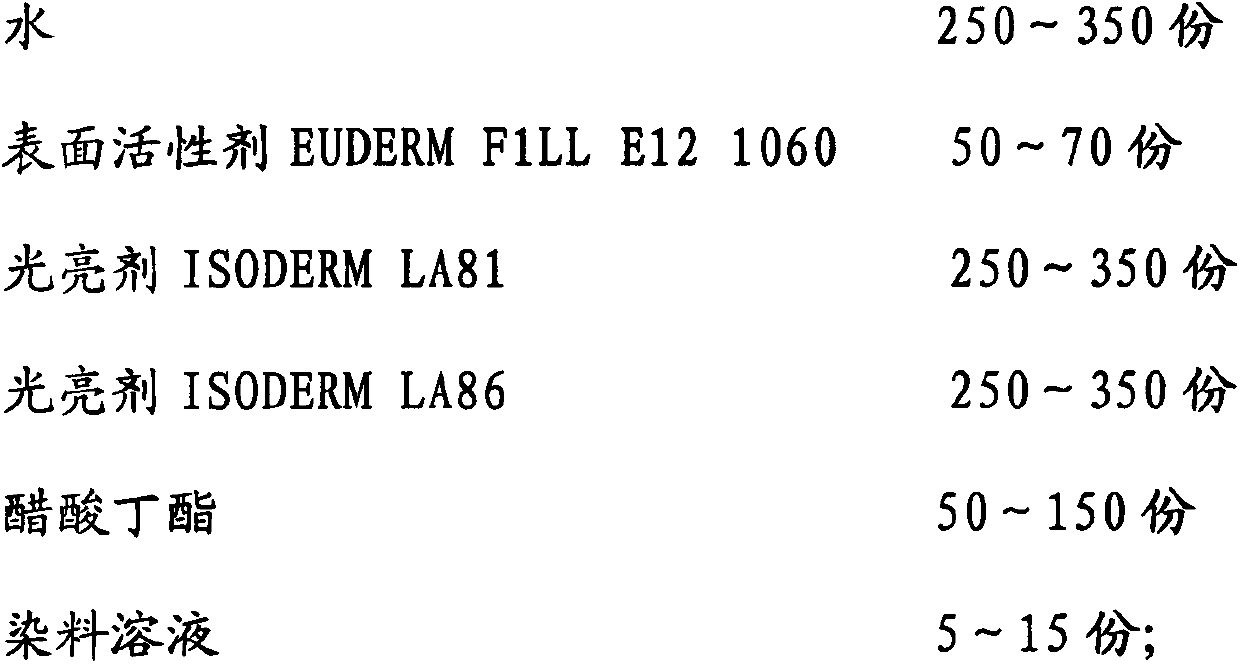

[0019] Based on processing 1 part by weight of leather to be treated, the treatment solution includes the following raw materials by weight:

[0020]

[0021] It should be noted that the raw materials involved in the above are all commercially available grades.

[0022] ② Preparation of treatment solution

[0023] Mix and stir water, surfactant EUDERM F1LL E121060, brightener ISODERM LA81, brightener ISODERM LA86, butyl acetate and dye solution, and transport them to the spraying equipment;

[0024] ③, color rubbing and finishing treatment

[0025] Flatten the leather to be treated, spray it with spraying equipment, iron it at 100°C and then polish it with a polishing cloth wheel;

[0026] ④. Repeat step ③ for 2 times.

Embodiment 2

[0028] The leather color rubbing and finishing treatment technology includes the following steps:

[0029] ①, the ratio of the treatment liquid

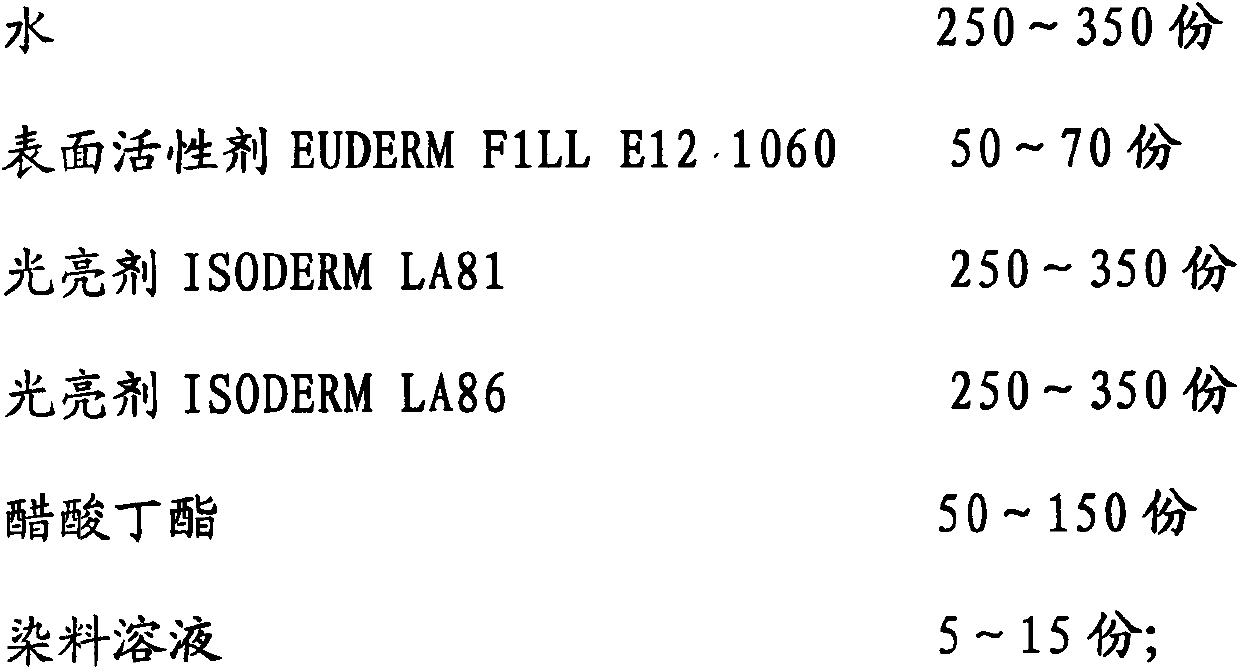

[0030] Based on processing 1 part by weight of leather to be treated, the treatment solution includes the following raw materials by weight:

[0031]

[0032] It should be noted that the raw materials involved in the above are all commercially available grades.

[0033] ② Preparation of treatment solution

[0034] Mix and stir water, surfactant EUDERM F1LL E121060, brightener ISODERM LAg1, brightener I SODERM LA86, butyl acetate and dye solution, and transport them to the spraying equipment;

[0035] ③, color rubbing and finishing treatment

[0036] Flatten the leather to be treated, spray it with spraying equipment, iron it at 100°C and then polish it with a polishing cloth wheel;

[0037] ④. Repeat step ③ 3 times.

Embodiment 3

[0039] The leather color rubbing and finishing treatment technology includes the following steps:

[0040] ①, the ratio of the treatment liquid

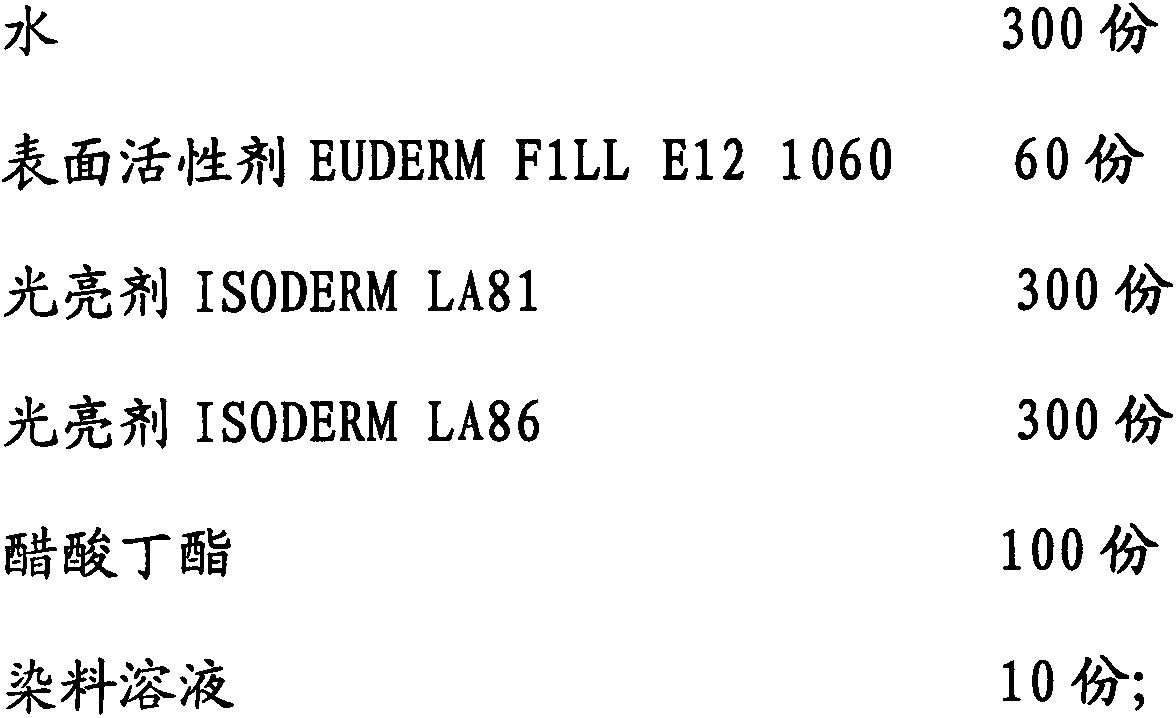

[0041] Based on processing 1 part by weight of leather to be treated, the treatment solution includes the following raw materials by weight:

[0042]

[0043] It should be noted that the raw materials involved in the above are all commercially available grades.

[0044] ② Preparation of treatment solution

[0045] Mix and stir water, surfactant EUDERM F1LL E121060, brightener ISODERM LA81, brightener ISODERM LA86, butyl acetate and dye solution, and transport them to the spraying equipment;

[0046] ③, color rubbing and finishing treatment

[0047] Flatten the leather to be treated, spray it with spraying equipment, iron it at 100°C and then polish it with a polishing cloth wheel;

[0048] ④. Repeat step ③ 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com