Double water circuit cooling zone melting induction coil

A technology of induction coils and cooling zones, applied in the field of induction coils, can solve the problems of unstable coil upper surface structure, unreasonable, uneven distribution of thermal field in silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

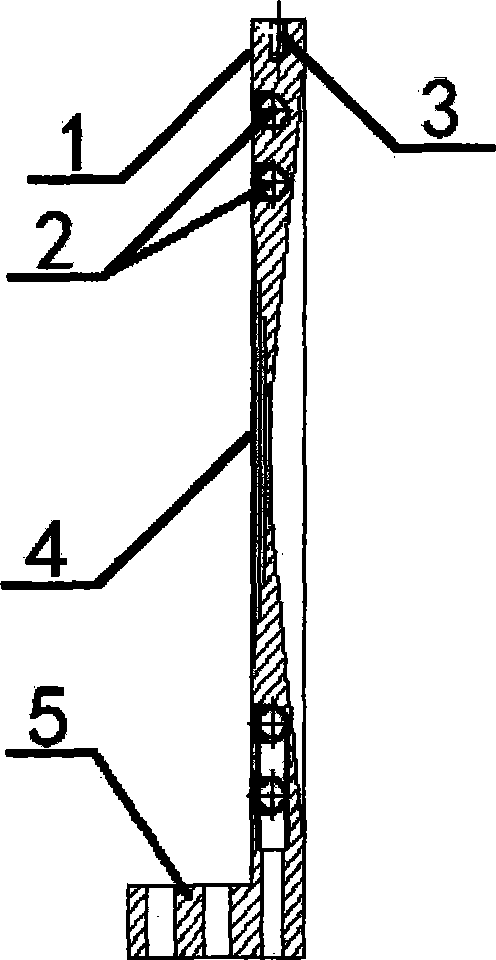

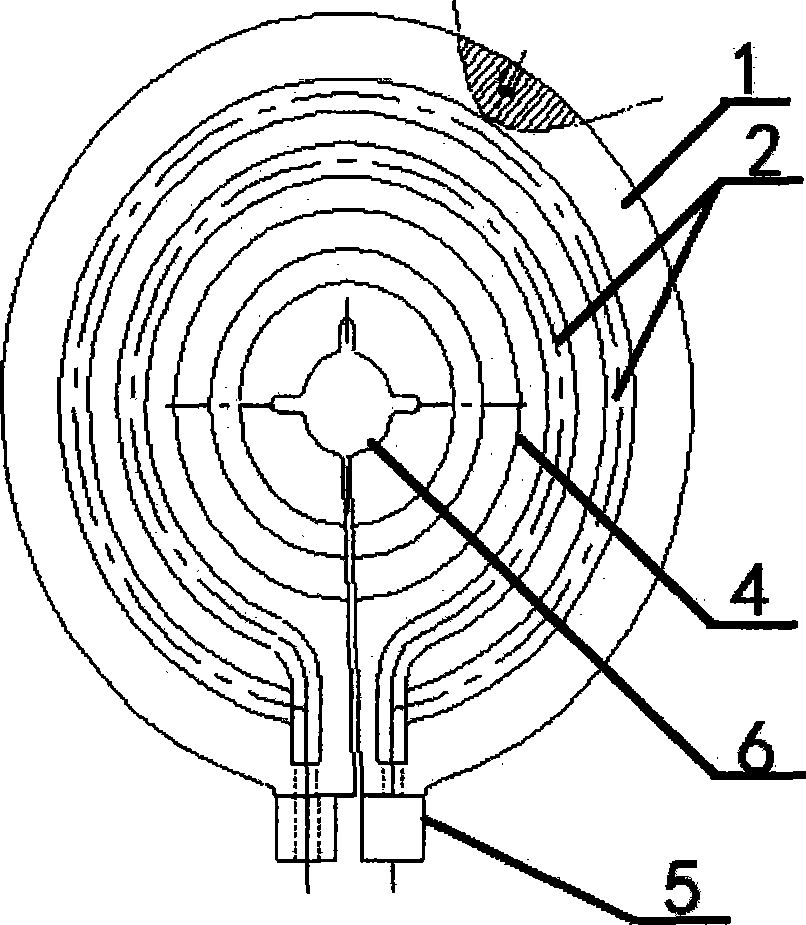

[0012] Such as Figure 1-2 As shown, the melting induction coil in the dual-water cooling zone described in the embodiment of the present invention includes a single-turn coil plate 1, and the single-turn coil plate 1 is composed of a coil current-gathering ring 4 and a cooling water pipe 2 inside and outside the coil, and is a flat single-turn coil. structure, in which the inner and outer cooling water pipes 2 are double-layered and welded on the periphery of the concentrating ring 4 and the nozzle extends to the position of the connecting flange 5 at the end of the single-turn coil plate 1; the edge of the single-turn coil plate 1 is provided with grounding holes 3. An inner circular hole 6 is set at the center of the flow collecting ring 4, where the upper surface of the flow collecting ring 4 is provided with three steps, and the diameter of the circle from the first step on the outside to the third step on the inside is step by step At the same time, the slope formed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com