Weft monitoring method and weft monitoring device for fluid jet loom

A fluid jetting and weft insertion device technology, applied in looms, textiles, papermaking, textiles, etc., can solve problems such as poor fabric quality, and achieve the effect of simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

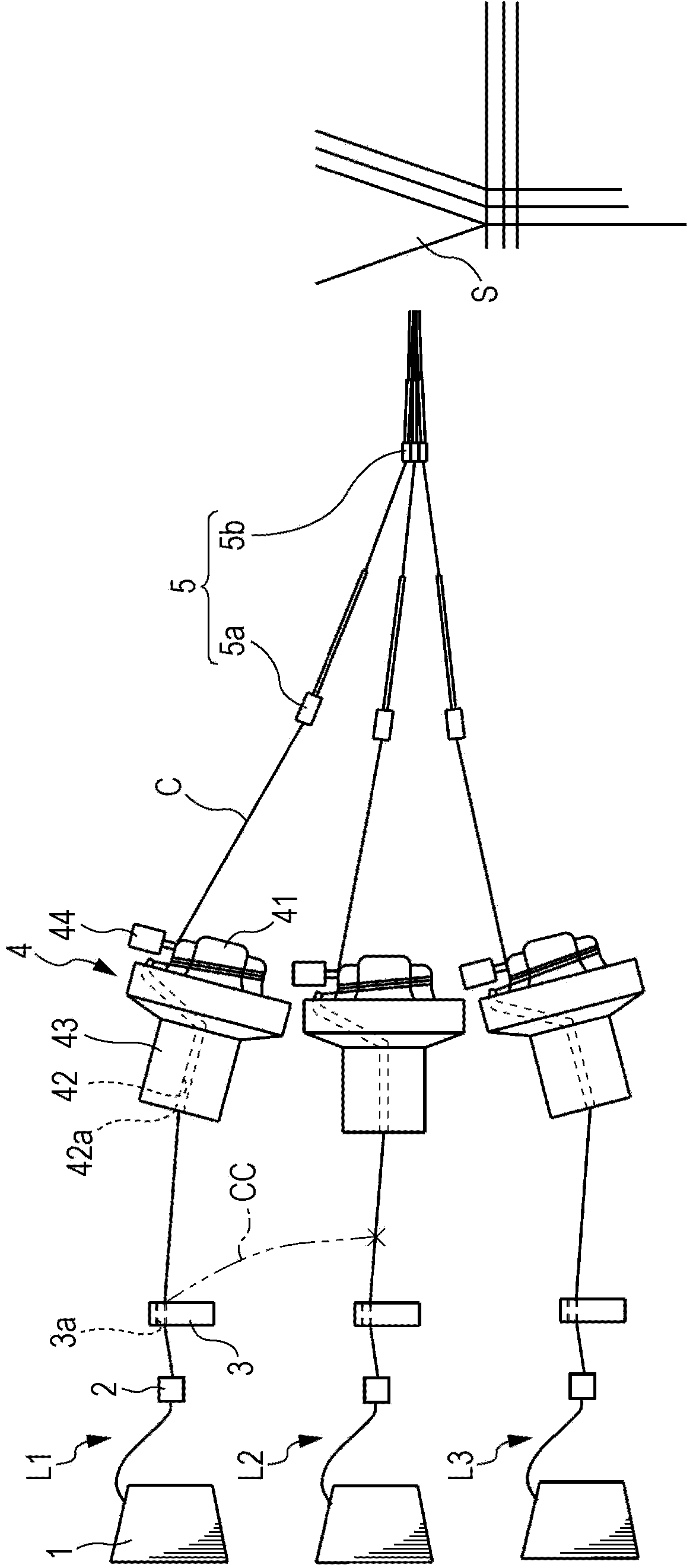

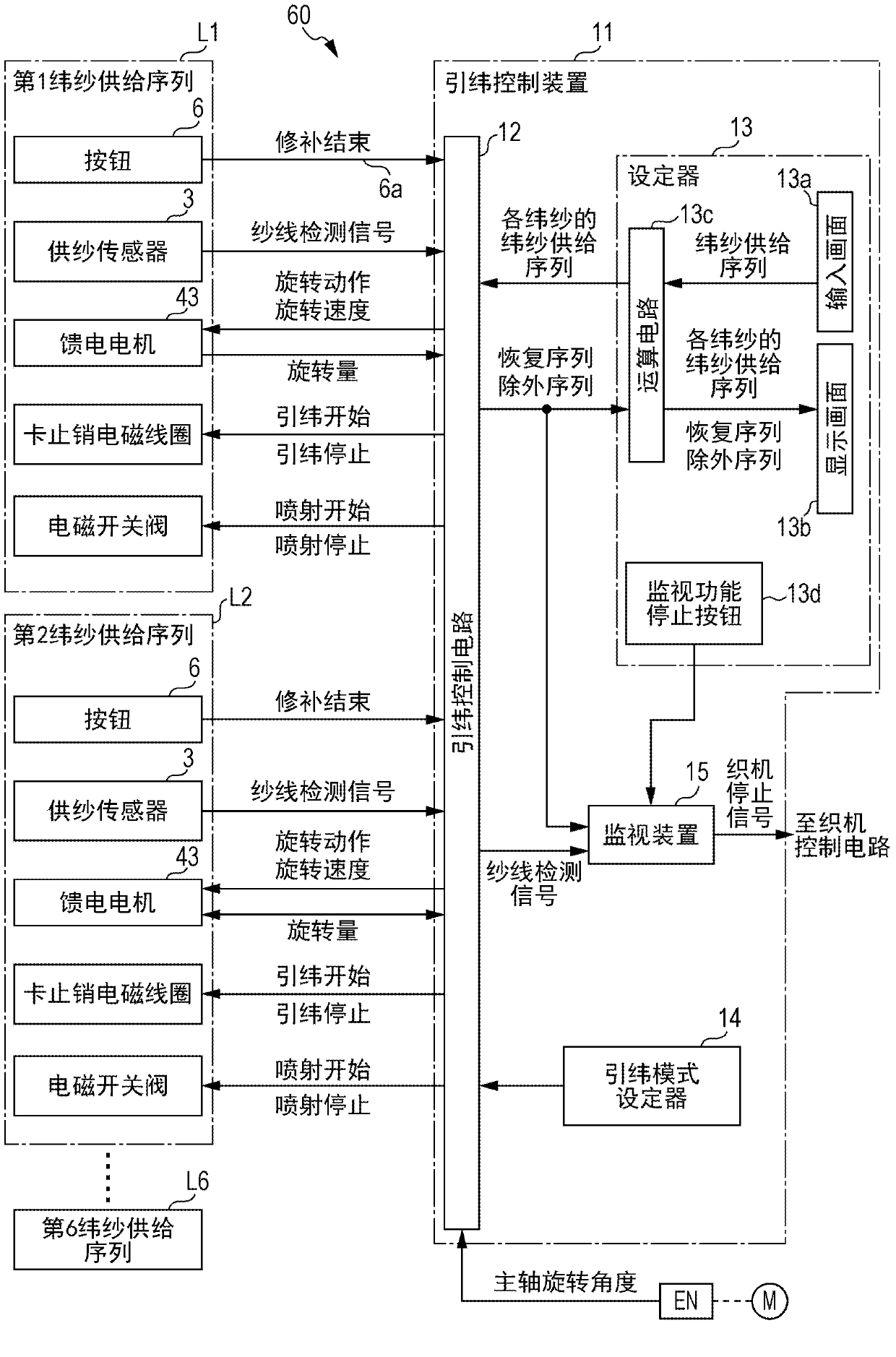

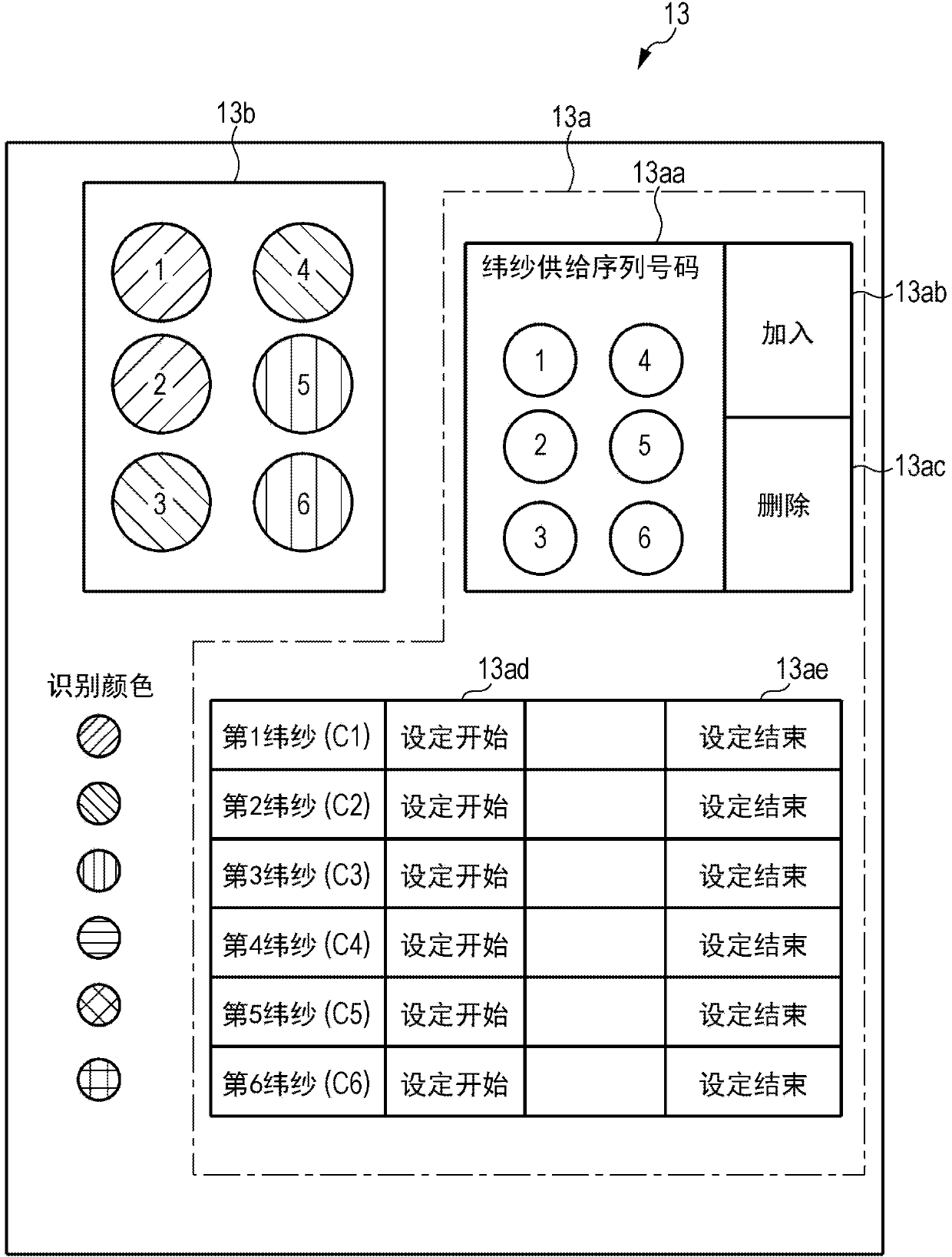

[0028] exist figure 1 In FIG. 2 , an example of a basic structure of a weft insertion device 60 used in an air jet loom as an example of a fluid jet loom to which the present invention is applied is shown in schematic form from a structural plane. The weft insertion device 60 of this example is a multi-color weft insertion device 60 that can insert a plurality of different types of weft yarns C according to a preset weft insertion pattern. In more detail, it is equipped with a sequence of 6 groups of weft yarn supply sequences ( L1-L6) come as a 6-color weft insertion device 60 of a plurality of weft yarn supply sequences L. in, figure 1 It is a figure viewed from the side of the weft insertion device 60, and the six sets of weft yarn supply sequences L1-L6 are respectively arranged in three sets on the near side and the back side. On this basis, figure 1 Only three sets of weft yarn supply sequences L1-L3 on the front side are shown in . Also, the plurality of weft yarn su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com