Concentric pipe heat tracing natural gas exploitation method and special tubular column

A mining method and technology for natural gas, which are applied in the fields of production of fluids, earthwork drilling, wellbore/well components, etc., to achieve the effects of protecting gas layers, improving production time, and reducing the intensity of workover operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The process steps of the concentric tube heat tracing natural gas mining method of the present invention are as follows:

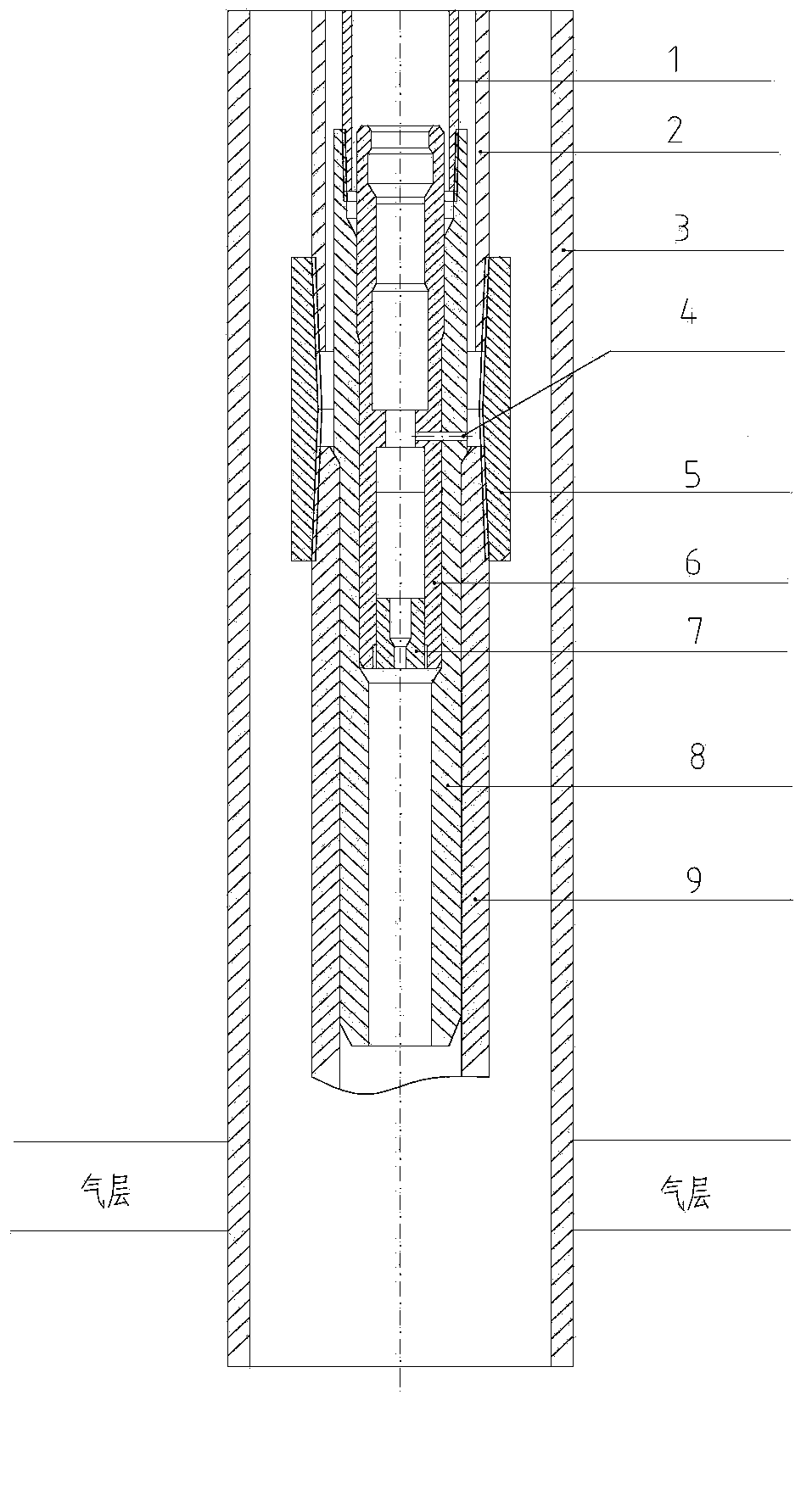

[0020] The first step is to assemble and lower the concentric tube heat tracing gas injection gas recovery process string. like figure 1 As shown, the concentric tube heat tracing gas injection gas production process string consists of tubing string 1, tubing string 2, casing string 3, connecting nipple 5, downhole choke main body 6, downhole choke nozzle 7, downhole choke flow device support body 8 and support body 9, the above-mentioned tubing string 2 is placed in the casing string 3, and the tubing string 2 is threadedly connected with the support body 9 through the connecting pup joint 5; the above-mentioned tubing string 1 is placed in the tubing string 2, and the tubing string The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com