Slip sheet expander

A technology of expander and sliding vane, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., which can solve the problem of increased friction power consumption of sliding vanes, straining the cylinder, and failure to realize the sliding vane expander without initial rotation. Start-up and other problems, to achieve the effect of miniaturization and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

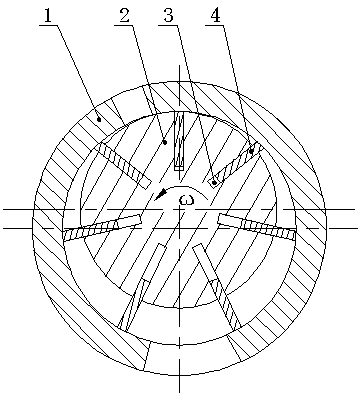

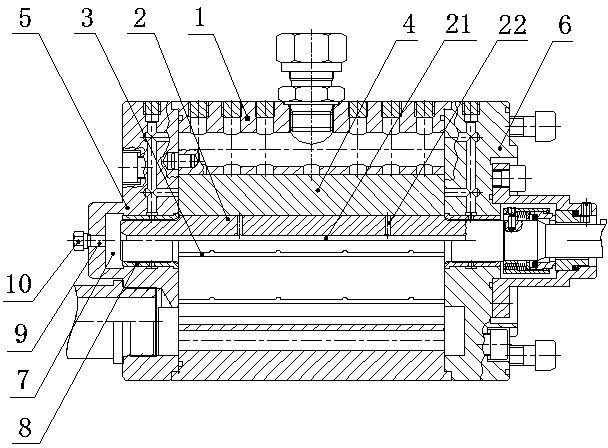

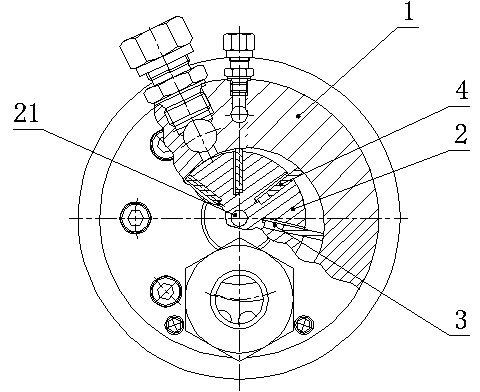

[0023] Such as figure 2 and image 3 As shown, the present invention includes a stator 1 containing a cylinder and a rotor 2 installed eccentrically in the stator cylinder. One side of the stator 1 is equipped with an exhaust end cover 5, and the other side of the stator 1 is equipped with an output shaft end cover 6. The inner side of the end cover 5 has a bearing positioning groove 7, and a bearing sleeve 8 is installed in the bearing positioning groove 7. One end of the rotor shaft is movably fitted on the bearing sleeve 8, and the other end of the rotor shaft protrudes from the output shaft end cover 6 to output power. The slot 3 is equipped with a sliding piece 4 that slides radially, the bearing positioning groove 7 of the exhaust end cover 5 is provided with a fluid through hole 9, and the end face of the rotor shaft located in the bearing positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com