Portable pneumatic cold blast valve for incinerator tail gas treatment system

A technology for exhaust gas treatment and incinerator, which is applied in the field of parts and components, can solve the problems of complex structure and laborious operation of the cold air valve, and achieve the effects of compact structure, safe operation and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

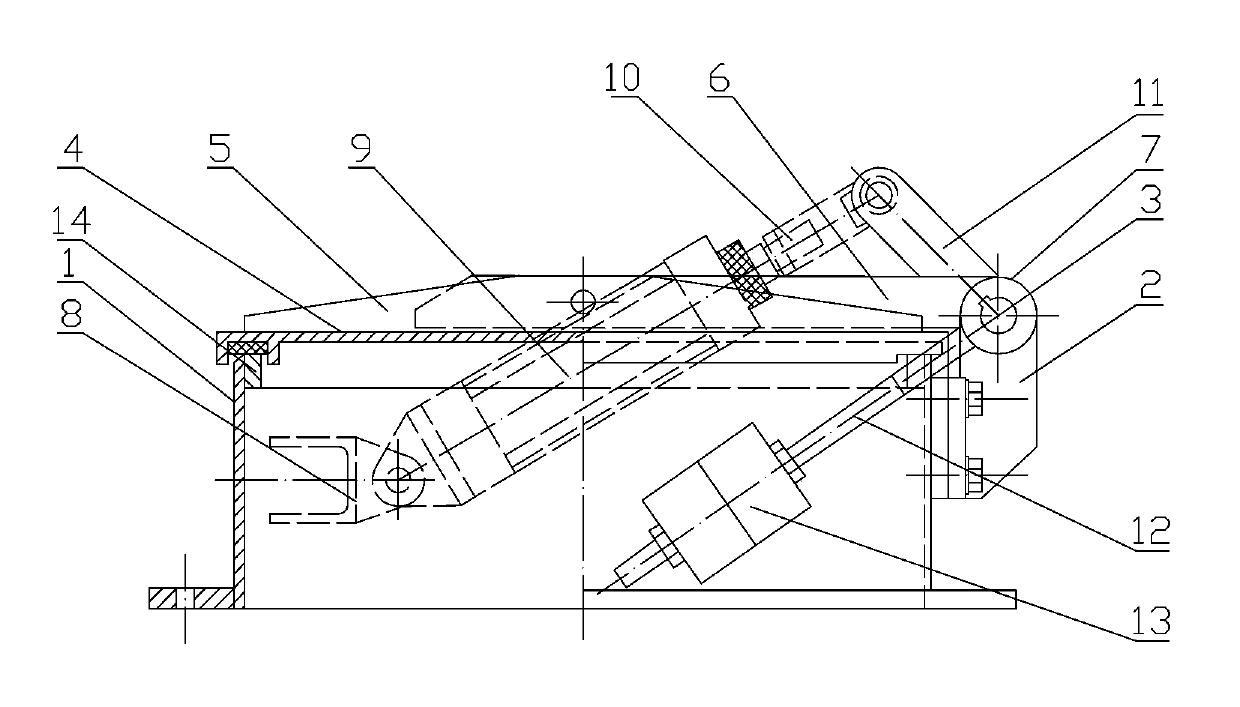

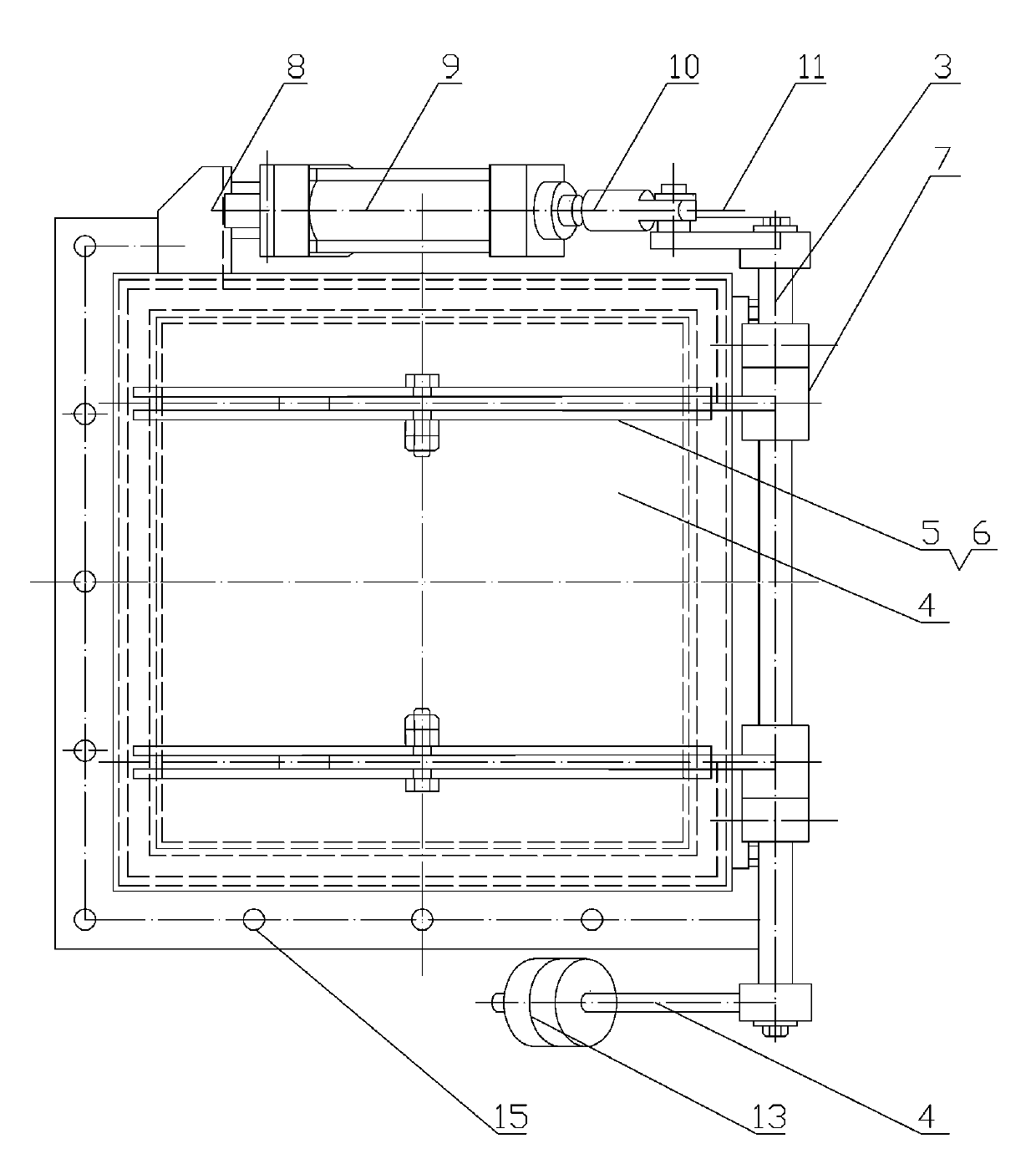

[0013] see figure 1 , figure 2 , the present invention has a housing 1, a shaft support 2 is welded on one side of the housing 1, and a main shaft 3 is fixed on the shaft support 2; There is a sealing strip 5, which is sealed and connected with the upper part of the housing 1. A rib plate 5 is formed on the upper surface of the gland 4. The rib plate 5 is connected with a flip rocker arm 6 by bolts. One end of the flip rocker arm 6 is welded with a shaft sleeve 7. The axle sleeve 7 is worn on the main shaft 3, especially: a cylinder support 8 is welded on the side adjacent to the main shaft 3 on the housing 1, the cylinder support 8 is equipped with a cylinder 9, and the cylinder piston head 10 is connected with a connecting rod. Bar 11, the other end of connecting rod 11 is hinged with an end of main shaft 3; On the other end of main shaft 3, counterweight bar 12 is housed, and counterweight block 13 is housed on counterweight bar 12.

[0014] In this embodiment, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com