Plug connector for fluid lines and retainer for such a plug connection

A plug-in connection, fluid conduit technology, applied in mechanical equipment, couplings, etc., can solve problems such as disadvantage and small assembly space, and achieve the effect of comfortable and reliable automatic or one-hand assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] For the following description, it needs to be emphasized that the present invention is not limited to these embodiments, and therefore is not limited to all or more features in the described combination of features; in fact, every single sub-component in any embodiment A feature still has inventive significance when it is separated from all other sub-features described together, whether it exists alone or in combination with any feature in another embodiment.

[0081] In the different figures, the same components are assigned the same reference numerals and therefore generally only need to be described once each.

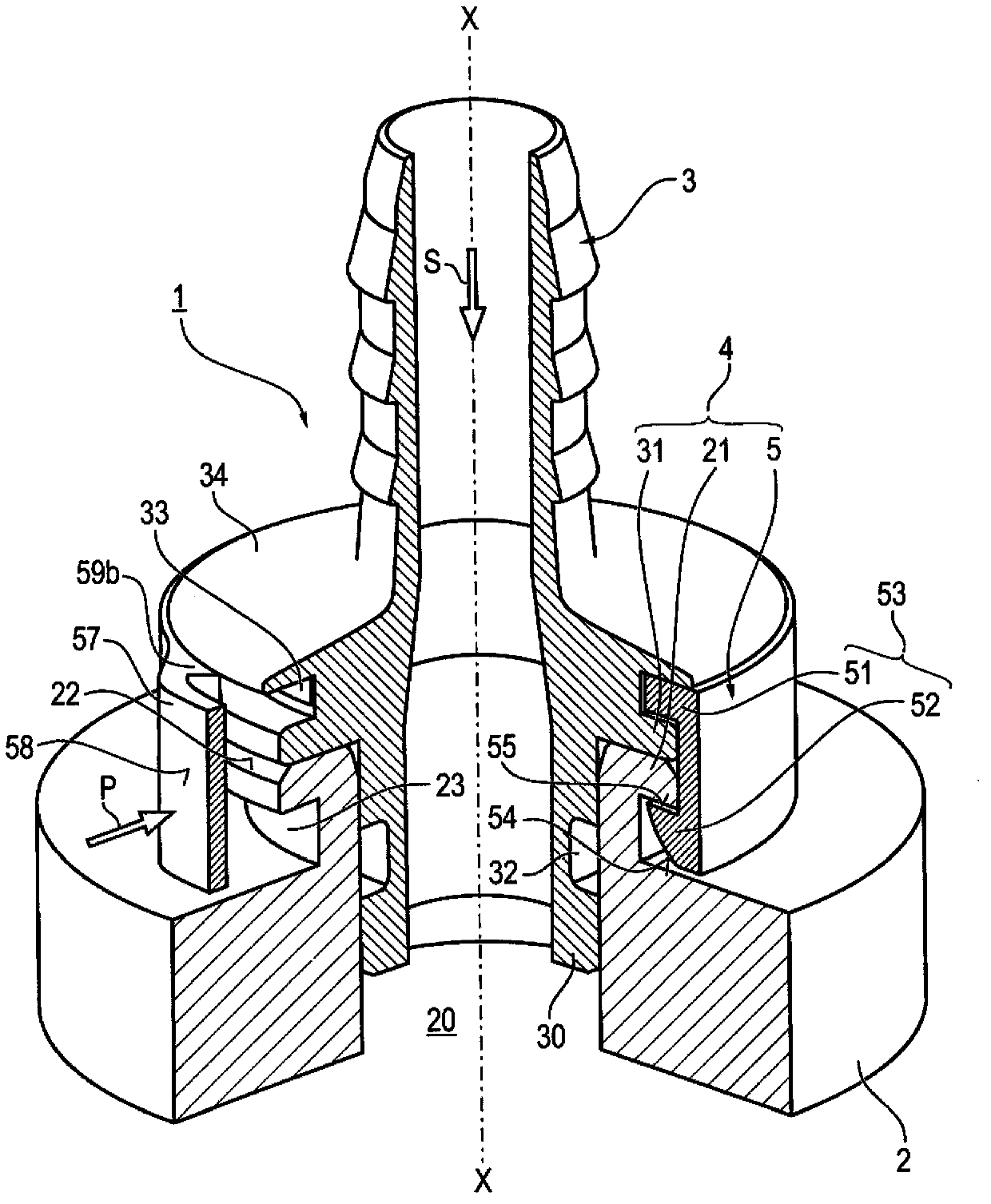

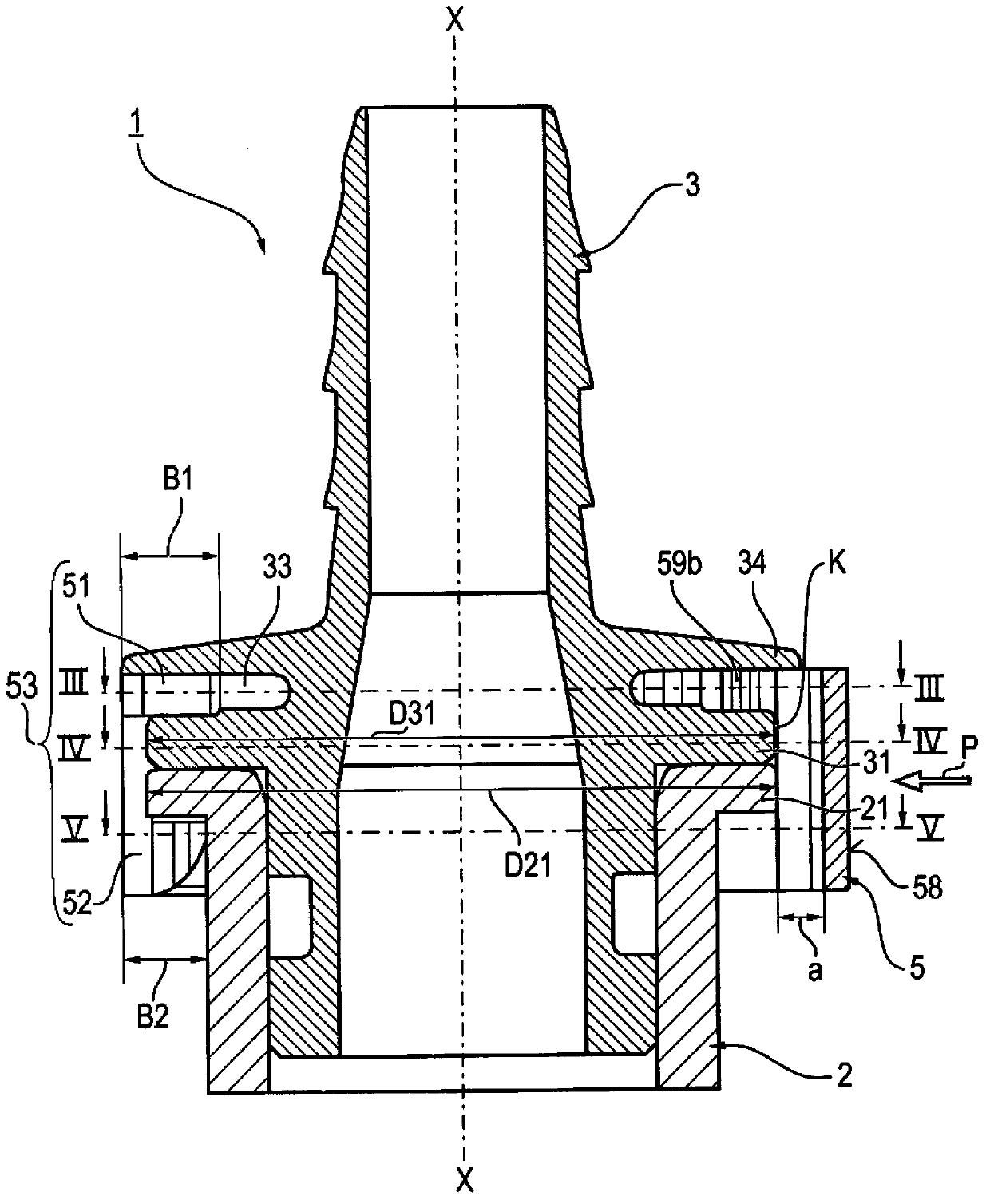

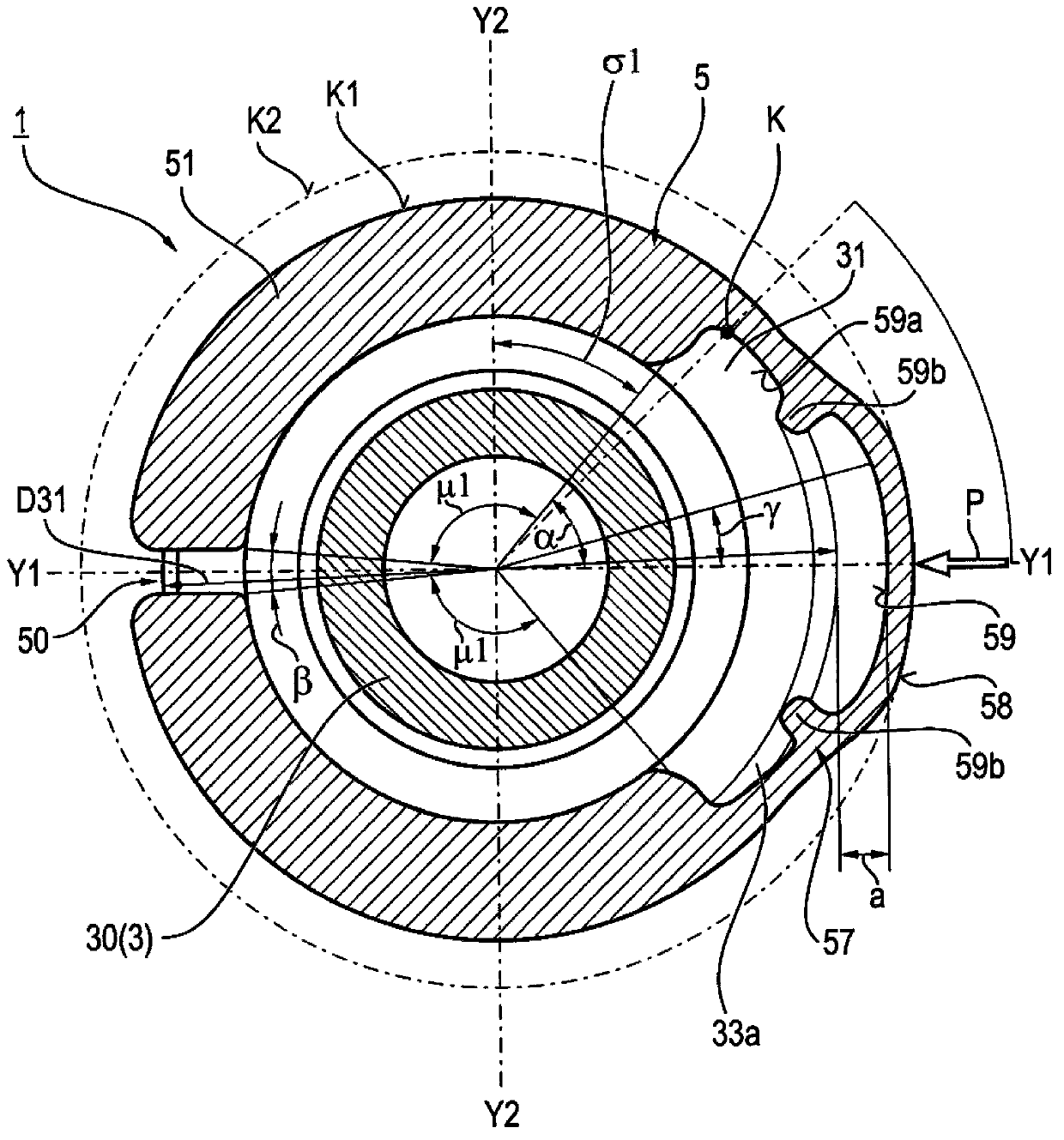

[0082] The plug-in connector 1 according to the invention, which is especially useful for connecting fluid conduits, comprises two coupling parts 2, 3 which can be plugged together, said coupling parts being figure 1 are inserted into each other in the assembled state shown in , and in this state can be releasably locked together coaxially with each other by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com